The Future of Reloading: How 3D Printed Bullet Feeder Guide to Change Efficiency

For competitive shooters and avid reloaders, speed and accuracy are crucial. The arduous process of putting bullets into a case alone can be an important bottleneck. Input Bullet Feeder Guide – A key component designed to simplify this step. Although traditionally made of metal or purchased in ready-made units 3D printing technology The fundamental change in how these tools are designed, produced and utilized. This innovation is more than just a novelty. This is a leap to enhance performance for anyone who is serious about reloading efficiency.

Limitations of traditional approaches: Why changes are needed

Historically, bullet feeder guides were produced in mass or handmade in fixed designs. This presents a challenge:

- Limited customization: Business guides are usually universal and designed for "Average" Bullet shape and caliber. They often struggle with specialized projectiles (such as long stern matching bullets or flat points) or unique loading pressure components.

- Cost and accessibility: Processing metal guides can be expensive, and custom manufacturing requires a lot of time and skill.

- Weight and Complexity: Metal conduits, while durable, increase the weight of the pressure assembly.

- Slow iteration: Perfecting the design based on user feedback or changes in bullet type is a slow, expensive process.

3D Printing: A Guide to Customizing the Perfect Bullet Feeder

Selective laser melting (SLM), metal jet fusion and advanced polymer printers have authorized engineers and shooters to overcome these limitations:

Unrivaled customization: This is 3D printed crown jewelry. Company engineers Great A guide to tailor-made feeder can be designed:

- Exact bullet configuration file: Perfectly accommodates lead round nose (LRN), full metal jacket (FMJ), hollow dot (HP), Spitzer, Wadcutter change or custom lathe into bullets.

- Specific caliber and press: Reload media models and caliber designs for your precise reload, ensuring seamless integration and optimal functionality.

- User Ergonomics: Adjust angle, height and feed path according to the operator’s preferred workflow.

Rapid prototype and iteration: The power of additive manufacturing shines here. Design defects identified during the test can be modified overnight in the CAD file. Compared to traditional CNC machining, new, improved iterations can be printed in hours or days and ready for testing in hours or days, greatly accelerating the development cycle. Greatlight’s advanced SLM printers make this fast turnaround a reality.

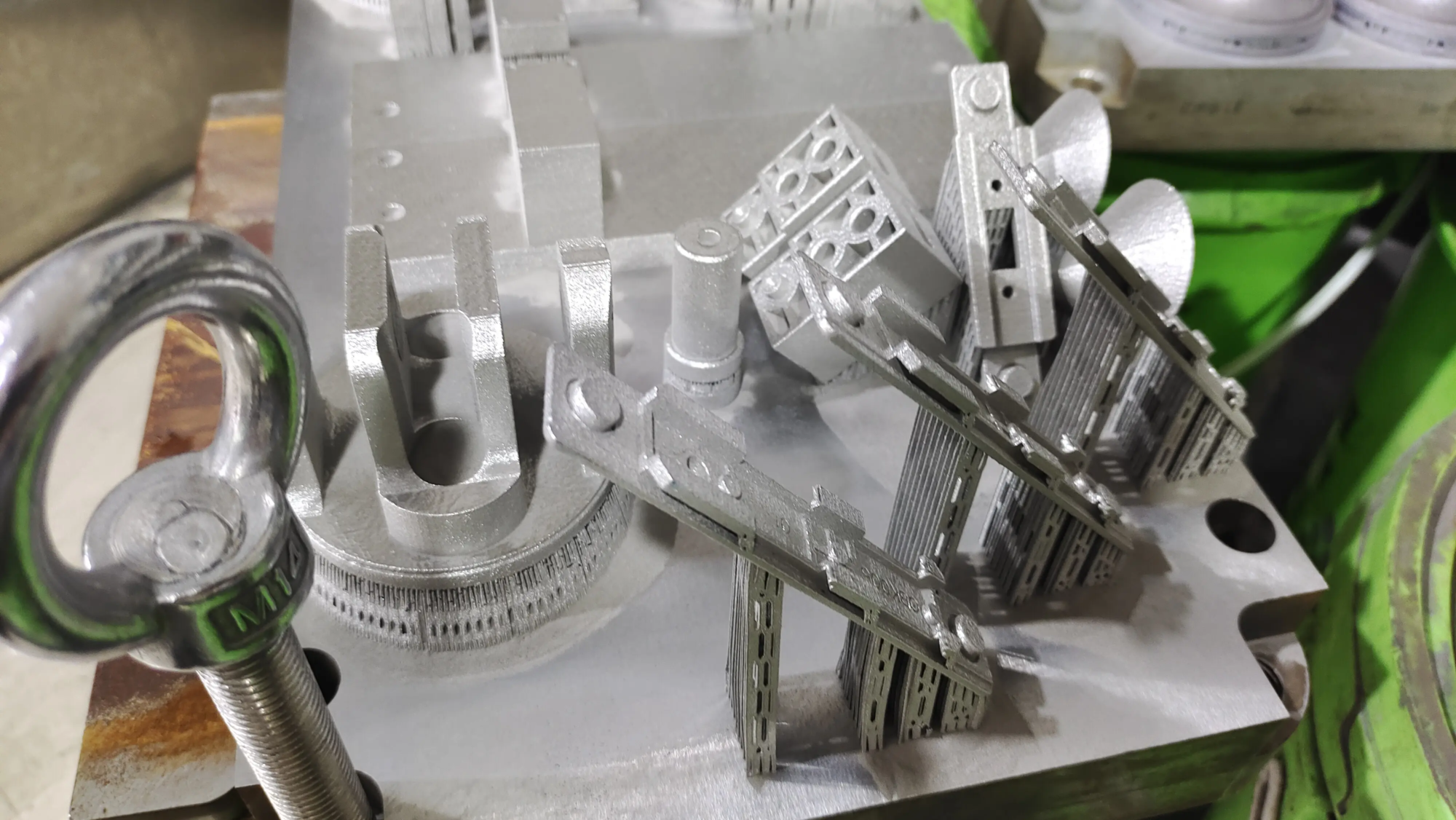

Lightweight accuracy: Printing guides can use internal lattice structures or optimized topological designs that maintain excellent stiffness and durability while significantly lighter than their actual core metal counterparts. This reduces news inertia and fatigue.

Material versatility: According to requirements, the guide can be printed in:

- Powerful polymers (PLA+, nylon, PETG): Ideal for cost-effective, lightweight solutions, especially for amateurs.

- Stainless steel (316L, 17-4PH): For unparalleled durability, wear resistance and massive reloading environments.

- Aluminum alloy (ALSI10MG): Provides excellent strength to weight ratio and good corrosion resistance.

- Titanium alloy (TI6AL4V): The ultimate strength and lightness, albeit with higher costs.

- Cost-effective: Eliminating complex machining setups and tools can significantly reduce production costs, especially for complex geometries or low to medium production volumes. Customization is no longer too expensive.

Great Benefits: Bring your custom feeder guide to your life guide

Turning a custom bullet feeder guide design into a high performance reality requires professional expertise and technology. This is Rapid prototyping Expertise:

- Advanced SLM technology: Our state-of-the-art selective laser melting (SLM) printers can make complex, intensive metal guides from over 30 metal powders, with incredible dimensional accuracy and mechanical properties matching or exceeds traditional manufacturing.

- Engineering level: Our team is more than just operators; they are engineers who understand ballistics, reload mechanics, and materials science. We work together to perfect the design for optimal performance and manufacturability.

- End-to-end production: From initial design consultation (CAD support) and material selection to precise AM manufacturing and comprehensive One-stop post-processing (including key steps such as heat treatment, pressure relief, grinding, CNC finish of critical surfaces, and passivation of stainless steel), Greglight manages the entire workflow.

- Quick customization: We specialize in research "Quick lead parts." How many days do you need a prototype or a quick customization guide? Our optimization process and capacity make it possible.

- Material flexibility: In addition to common alloys, we also process many technical metals to meet specific strength, weight or environmental requirements.

Real-world impact: accurate achievement of efficiency

Use unique 6mm matching bullets to consider a highly competitive shooting game, unusually long. Ready-to-use plastic guides are always clogged, slowing down reloading and causing frustration. Cooperate with it Greatwe designed a stainless steel (17-4ph) guide:

- Complete customization: The inner profile matches the smooth profile of the bullet very well.

- Optimized feed path: Minimize friction and ensure consistent vertical orientation.

- High-end interface: Print critical contact density increases and completes to smooth surfaces.

- Lightweight power: The internal fill mode reduces weight without sacrificing rigidity.

result? Eliminate jam, faster loading times, and enhanced consistency – directly helping to better scores on the radiator.

Conclusion: Precision Solution Evolution

The 3D-printed bullet feeder guide reflects how advanced manufacturing can transform shooting sports and precision decoration. It moves from universal tradeoffs to tailor-made perfection. Agility Rapid prototypingespecially with the ability to quickly and cost-effectively produce robust metal parts through SLM technology, enabling shooters and engineers to solve specific challenges with unprecedented efficiency.

For enthusiasts who demand peak performance and seek a variety of competitive advantages, embracing custom 3D printing solutions is no longer futuristic and practical. Great Standing at the forefront of this development, equipped with cutting-edge technology and deep engineering expertise. We can turn your vision of the perfect reload accessories into a faster and more affordable feature reality than ever before. Unlock the potential for custom efficiency on reload benches.

FAQ: 3D Printed Bullet Feeder Guide

Is the 3D printed bullet feeder guide durable enough?

- Absolutely. They are extremely durable when printed with high-quality engineering practices and appropriate materials, especially through metals such as SLM stainless steel or aluminum, or reinforced polymers such as nylon or PA-CF. The metal printing guide provides wear resistance and strength comparable to machined parts. Polymer guides are sufficient for many applications, but naturally have limitations in high-volume or high-clothing scenarios.

How much does a custom 3D printed bullet feeder guide cost?

- Costs vary widely based on complexity, size, material and post-processing requirements. Simple polymer design is very economical. Metal printing guides using advanced technologies such as SLM are more investment-oriented, but provide a high life and performance reason for serious users. Great Provide competitive, transparent quotes based on your specific design and needs.

What information do I need to provide to customize the guide?

- Key details include:

- Bullet Specifications: Detailed drawings, CAD models (ideal) or precise physical dimensions/caliber/profile details.

- By manufacturing and model: A specific bullet feeding station or death connects it to (e.g., Dillon, Hornardy, Lee).

- Material preference: Cost/weight polymer, metal durability (discuss options with us).

- Functional requirements: Need any special features?

- Key details include:

How long does it take to get a custom 3D printing guide?

- Rapid prototyping greatly reduces lead time. Simple polymer concepts can be reversed in a few days. Complex metal designs printed by SLM, including necessary post-processing, are usually employed 1-2 weeksmuch faster than custom parts in traditional manufacturing. Great priority "Quick lead parts" The timeline is critical.

Can I print bullet feeder guide on my desktop FDM printer?

- Yes, you can print functional prototypes with hard plastics such as nylon, PLA+ or PETG or low-volume usage guide. This is perfect for testing and lightweight use. However, for reusable reloads, consistent feeding and lifespan (especially larger calibers or repeated operations), metal printing guides, made by professionals Great Using SLM technology is superior. Under pressure, desktop printing may wear or deform rapidly.

- Is this 3D printed gun part legal?

- Important: Always comply with all federal, state and local laws. bullet Feeder Guide It is usually considered a reload tool attachment, no Regulated gun components. It does not interact with the shooting mechanism. However, definitions and regulations vary by jurisdiction. Great Strictly produce components of legal applications and advise customers to fully understand and comply with all applicable laws regarding the manufacture and possession of any firearm-related items.