ISO 9001 Factory

ISO 9001 Factory

Great Light is the source factory of metal 3D printing and a one-stop service platform for Industrial-grade Metal 3D Printing, providing customized 3D printing services and comprehensive solutions for nearly 100 materials.

Click here to upload or drag and drop your model to the canvas.

Click here to upload or drag and drop your model to the canvas.

The model is too large and has been resized to fit in the printer's build tray. [Hide]

The model is too large to fit in the printer's build tray. [Hide]

The model is too large, a fitting printer is selected. [Hide]

The model is too small and has been upscaled. [Hide]

Warning: The selected printer can not print in full color [Hide]

Warning: obj models with multiple meshes are not yet supported [Hide]

Warning: Unsupported DXF entity [Hide]

Warning: could not arrange models [Hide]

X:

×

Y:

×

Z:

cm

X:

×

Y:

×

Z:

cm

Model Stats:

| Material Volume: |

cm3

cm3 |

| Support Material Volume: |

cm3

cm3 |

| Box Volume: | cm3 |

| Surface Area: | cm2 |

| Model Weight: |

g

g |

| Model Dimensions: |

x x

cm |

| Number of Polygons: | |

| Number of Shapes: | |

| Total Path: |

cm

cm |

| Print Time (hh:mm:ss): |

|

Unit Price:

Great Light offers 3D Printing and low volume manufacturing. We’ve boiled our innovation process down to four simple steps that work.

Upload your part to see if it’s eligible.

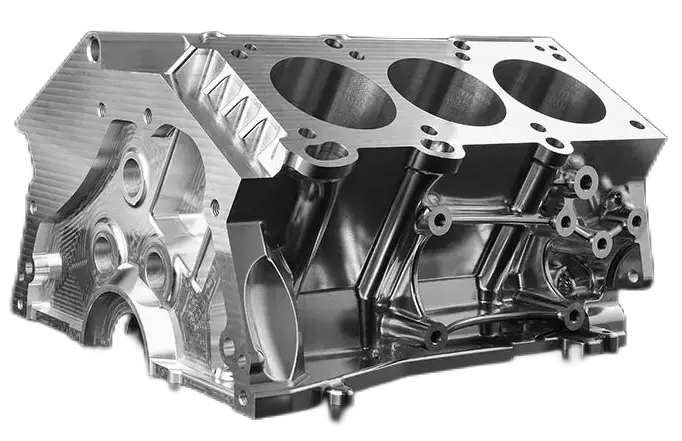

Faster, easier, higher quality on-demand manufacturing of metal parts

Features:

Austenitic stainless steel, with high strength and corrosion resistance, can be reduced to low temperature in a wide temperature range. The overall performance of this steel is better than 310 and 304 stainless steel. 316L stainless steel also has good resistance to chloride corrosion.

Application areas:

Auto parts, household appliances, electromechanical equipment

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥560MPa | ≥480MPa | ≥30% | ≥90HV |

| Heat Treated Properties | ≥530MPa | ≥380MPa | ≥32% | ≥230HV |

Features:

A typical casting alloy with good casting properties, used for printing thin walls and complex geometric designs. This alloy contains silicon/magnesium, which significantly enhances strength and hardness, while also having good dynamic properties.

Application areas:

Auto parts, household appliances, electromechanical equipment

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥290MPa | ≥200MPa | ≥5% | ≥65±5HBW |

| Heat Treated Properties | ≥430MPa | ≥260MPa | ≥3% | ≥120±5HBW |

Features:

It has the advantages of reducing molding cycle, improving product quality, and making the mold temperature field more uniform. It can print the front and rear cores, inserts, sliders, guide pillars and hot runner water jackets of injection molds.

Application areas:

Mould, Automobile

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥950MPa | ≥900MPa | ≥5% | ≥32HRC |

| Heat Treated Properties | ≥1090MPa | ≥1000MPa | ≥10% | ≥48HRC |

Features:

This famous light alloy is characterized by good mechanical properties, strong corrosion resistance, low weight and good biocompatibility. It is the most widely used material for many engineering parts and biomedical implants.

Application areas:

1. Lightweight structures and parts (such as structural parts and aircraft engine parts used in the aerospace field, automotive parts, etc.).

2. Biomedical implants (such as bone plates, trabeculae, porous structures and other orthopedic implants).

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥900MPa | ≥800MPa | ≥2% | ≥200HBC |

| Heat Treated Properties | ≥1000MPa | ≥900MPa | ≥4% | ≥294HBC |

Features:

It has high tensile strength, fatigue strength, creep strength and fracture strength at 700℃; high oxidation resistance at 1000℃; stable chemical properties at low temperatures; and good welding performance.

Application areas:

Steam turbines, liquid fuel rockets, cryogenic engineering, acidic environments, nuclear engineering.

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥900MPa | ≥650MPa | ≥10% | ≥253HBC |

| Heat Treated Properties | ≥980MPa | ≥700MPa | ≥12% | ≥283HBC |

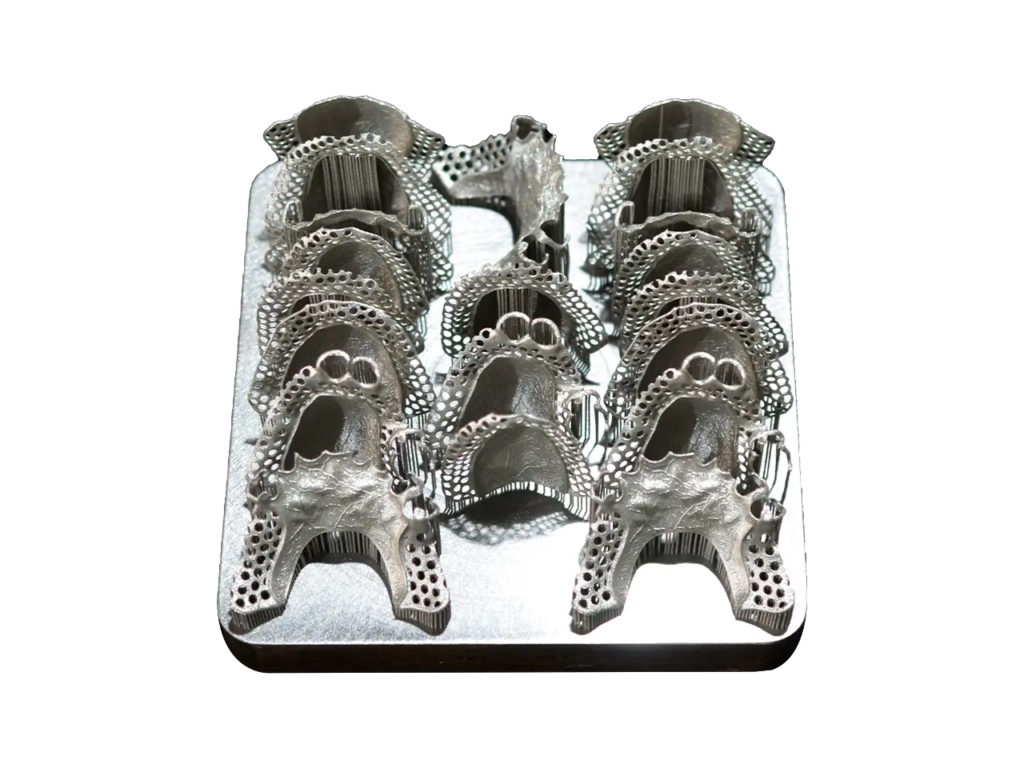

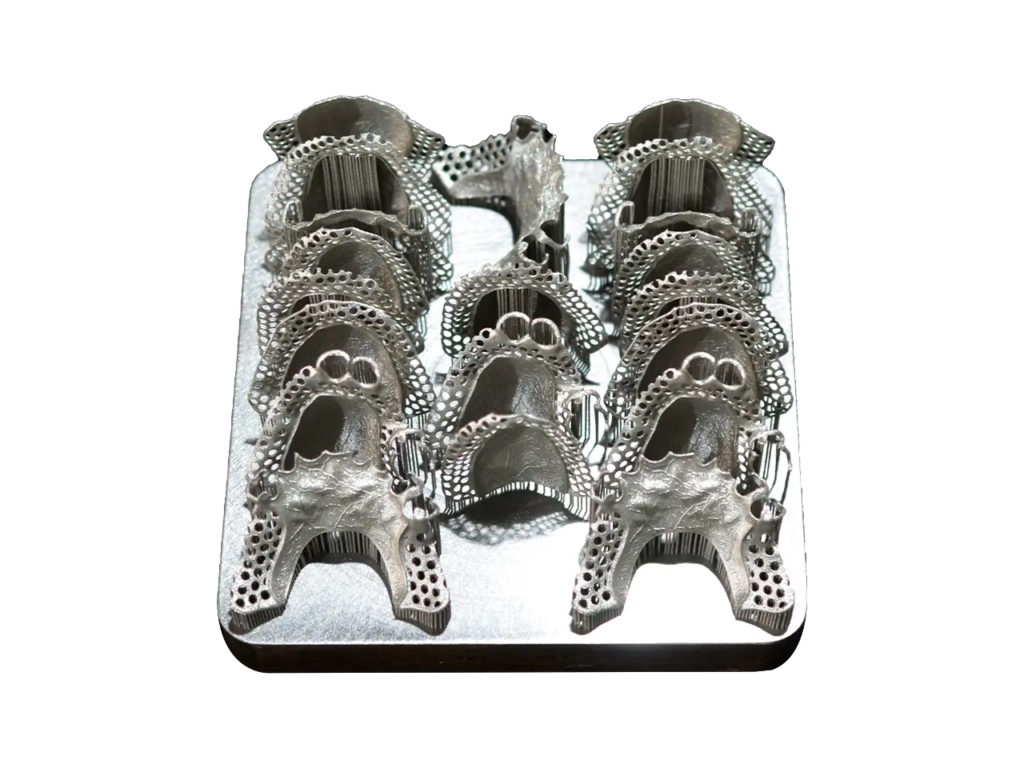

Features:

Cobalt-chromium alloy refers to a high-temperature alloy with cobalt and chromium as the main components. It has excellent corrosion resistance and mechanical properties. The parts made of it are high-strength, high-temperature resistant, and have outstanding biocompatibility.

Application areas:

Medical field (such as orthopedic implants, dental crowns, stents, etc.).

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥900MPa | ≥750MPa | ≥5% | ≥228HBC |

| Heat Treated Properties | ≥1000MPa | ≥900MPa | ≥10% | ≥328HBC |

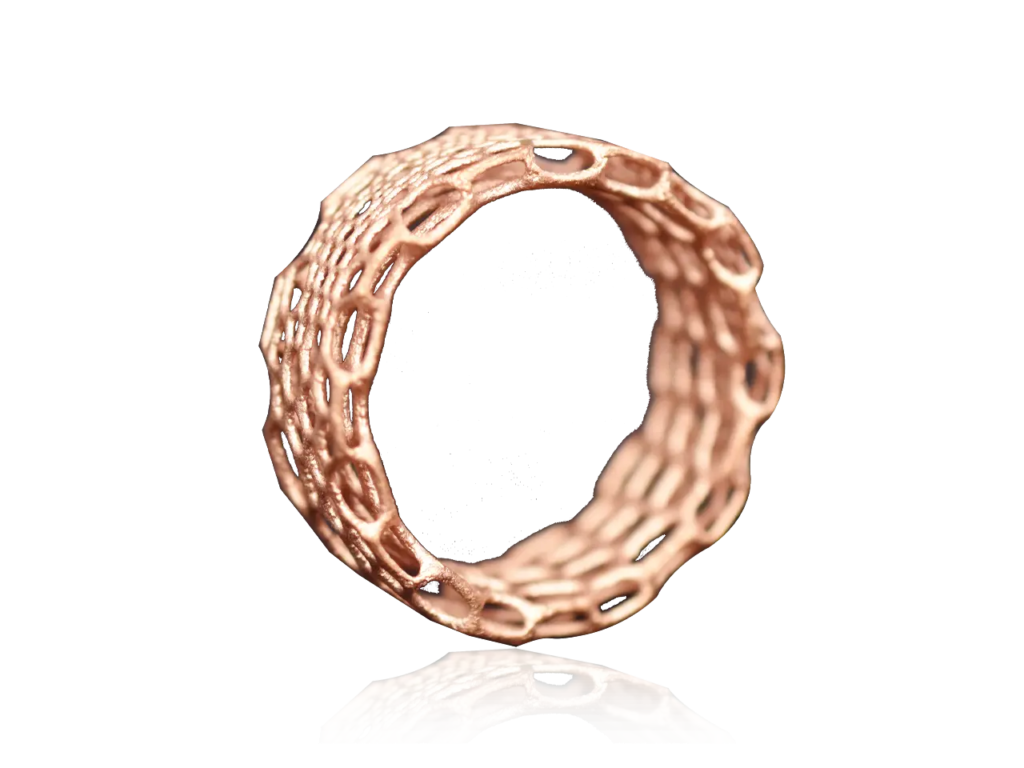

Features:

Bronze with tin as the main alloying element. The tin content is generally between 3% and 14%, and it is mainly used to make elastic components and wear-resistant parts.

Application areas:

Electrical wires, engine coils, printed circuits, roofing materials, plumbing materials, heating materials, jewelry, etc.

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥150MPa | ≥90MPa | ≥2% | ≥34HBC |

| Heat Treated Properties | ≥230MPa | ≥130MPa | ≥5% | ≥48HBC |

Features:

Chromium bronze is a copper alloy containing 0.4% to 1.1% Cr. Chromium bronze is widely used in high-temperature conductive and wear-resistant parts of electrical equipment.

Application areas:

Motor commutators, collector rings, high temperature switches, welding machine electrodes, rollers, clamps, brake discs and discs used in bimetallic form, and other parts requiring high thermal conductivity, electrical conductivity, and high thermal strength.

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥240MPa | ≥90MPa | ≥2% | ≥34HBC |

| Heat Treated Properties | ≥300MPa | ≥160MPa | ≥5% | ≥48HBC |

Faster, easier, higher quality on-demand manufacturing of metal parts

Features:

Austenitic stainless steel, with high strength and corrosion resistance, can be reduced to low temperature in a wide temperature range. The overall performance of this steel is better than 310 and 304 stainless steel. 316L stainless steel also has good resistance to chloride corrosion.

Application areas:

Auto parts, household appliances, electromechanical equipment

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥560MPa | ≥480MPa | ≥30% | ≥90HV |

| Heat Treated Properties | ≥530MPa | ≥380MPa | ≥32% | ≥230HV |

Features:

A typical casting alloy with good casting properties, used for printing thin walls and complex geometric designs. This alloy contains silicon/magnesium, which significantly enhances strength and hardness, while also having good dynamic properties.

Application areas:

Auto parts, household appliances, electromechanical equipment

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥290MPa | ≥200MPa | ≥5% | ≥65±5HBW |

| Heat Treated Properties | ≥430MPa | ≥260MPa | ≥3% | ≥120±5HBW |

Features:

It has the advantages of reducing molding cycle, improving product quality, and making the mold temperature field more uniform. It can print the front and rear cores, inserts, sliders, guide pillars and hot runner water jackets of injection molds.

Application areas:

Mould, Automobile

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥950MPa | ≥900MPa | ≥5% | ≥32HRC |

| Heat Treated Properties | ≥1090MPa | ≥1000MPa | ≥10% | ≥48HRC |

Features:

This famous light alloy is characterized by good mechanical properties, strong corrosion resistance, low weight and good biocompatibility. It is the most widely used material for many engineering parts and biomedical implants.

Application areas:

1. Lightweight structures and parts (such as structural parts and aircraft engine parts used in the aerospace field, automotive parts, etc.).

2. Biomedical implants (such as bone plates, trabeculae, porous structures and other orthopedic implants).

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥900MPa | ≥800MPa | ≥2% | ≥200HBC |

| Heat Treated Properties | ≥1000MPa | ≥900MPa | ≥4% | ≥294HBC |

Features:

It has high tensile strength, fatigue strength, creep strength and fracture strength at 700℃; high oxidation resistance at 1000℃; stable chemical properties at low temperatures; and good welding performance.

Application areas:

Steam turbines, liquid fuel rockets, cryogenic engineering, acidic environments, nuclear engineering.

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥900MPa | ≥650MPa | ≥10% | ≥253HBC |

| Heat Treated Properties | ≥980MPa | ≥700MPa | ≥12% | ≥283HBC |

Features:

Cobalt-chromium alloy refers to a high-temperature alloy with cobalt and chromium as the main components. It has excellent corrosion resistance and mechanical properties. The parts made of it are high-strength, high-temperature resistant, and have outstanding biocompatibility.

Application areas:

Medical field (such as orthopedic implants, dental crowns, stents, etc.).

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥900MPa | ≥750MPa | ≥5% | ≥228HBC |

| Heat Treated Properties | ≥1000MPa | ≥900MPa | ≥10% | ≥328HBC |

Features:

Bronze with tin as the main alloying element. The tin content is generally between 3% and 14%, and it is mainly used to make elastic components and wear-resistant parts.

Application areas:

Electrical wires, engine coils, printed circuits, roofing materials, plumbing materials, heating materials, jewelry, etc.

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥150MPa | ≥90MPa | ≥2% | ≥34HBC |

| Heat Treated Properties | ≥230MPa | ≥130MPa | ≥5% | ≥48HBC |

Features:

Chromium bronze is a copper alloy containing 0.4% to 1.1% Cr. Chromium bronze is widely used in high-temperature conductive and wear-resistant parts of electrical equipment.

Application areas:

Motor commutators, collector rings, high temperature switches, welding machine electrodes, rollers, clamps, brake discs and discs used in bimetallic form, and other parts requiring high thermal conductivity, electrical conductivity, and high thermal strength.

| Molding Process And Status | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation After Fracture (%) | Hardness (HBC) |

|---|---|---|---|---|

| Printing Performance | ≥240MPa | ≥90MPa | ≥2% | ≥34HBC |

| Heat Treated Properties | ≥300MPa | ≥160MPa | ≥5% | ≥48HBC |

One of the Best Rapid Prototyping Companies from China, Great Light 3D Printing Center is an ISO 9001:2015 certified manufacturer, specializing in custom metal and plastic parts. With advanced metal 3D printing technologies, we can rapidly produce complex parts directly from your 3D designs. Whether you need high-performance components for aerospace, automotive, or medical applications, our metal 3D printing services offer quick turnaround times and unparalleled precision. We can manufacture prototypes and final products using a variety of materials, including stainless steel, aluminum alloy, titanium alloy, and mold steel, and deliver finished parts in just a few days.

Affordable Price

Precision and Accuracy

Consistent Quality

Increased Productivity

Active client with positive reviews

We provide turnkey solutions for new products from concept to 3D Printing rapid prototyping and low-volume manufacturing, CNC machining, die casting, post-processing to assembly.

Unlock limitless design possibilities with our cutting-edge 3D Printing Processing Services—where precision meets speed to bring your ideas to life in metal and plastic!

Empower your innovation with our state-of-the-art 3D printers—precision, reliability, and performance tailored to elevate your creations!

Discover and trade high-quality 3D models effortlessly—your one-stop solution for bringing creative ideas to life!

Fuel your 3D printing projects with top-grade supplies—premium materials and accessories designed for superior performance and flawless results!

Great Light’s quality service policy: Keep improving, craft each product with craftsmanship, ensure excellent quality and efficient service, and meet the diverse needs of customers.

Here’s what our satisfied customers have to say about how we met their needs, Their words speak louder than ours.

Designer

Thrilled with the fast 3D Printing production and top-notch parts! Excellent service and flawless surface finishes. Great job!

Business Owner

The level of expertise of their engineers and their ability to complete these projects in a short period of time is commendable and worthy of recognition.

Designer

The results were outstanding. We were manufacturing a large housing component for an aerospace application with extremely complex hole geometry.

Business Owner

Had a great experience with GreatLight! Alice’s communication and dedication were excellent, and the product quality exceeded expectations. Highly recommend!

Businessman

They handled all aspects of this turnkey project quickly, professionally, and cost-effectively. We look forward to working with them again on future projects.

Business Owner

This is the most professional 3D Printing service provider I have ever worked with and it has been a pleasure to work with them since day one. I have been in procurement for over 15 years and have worked on many projects with suppliers from all over the world.

Business Owner

I have been with them from the beginning and have seen this progress and I am very satisfied. Thanks again to all of you and everyone else behind the scenes for doing a great job.

Business Owner

Great Light can handle your parts whether you need a few parts or over 10,000 end-use units. Check out the variety of custom 3D Printing services we offer to take your designs from concept to reality quickly and accurately.

Firstly, our team will inspect all incoming material. Secondly, our QC team will inspect parts during machining and the finished parts after all machining completed.

Please contact us via our online platform or Email, and send us your drawings of 2D and 3D (.STEP or .IGE file) and detail requirements. Then we will analyse your part design and submit competitive price to you.

Yes, we can support making prototypes with 3D Printing process for your assembly and testing before high volume production.

We normally ship samples via DHL, UPS or FedEX . For the shipping of mass production order, we usually arrange it by sea or by air.

Factory is about 7,600 square meters, With 150 employees, Equipped with large high-precision 5-Axis, 4-Axis, 3-Axis CNC Machining centers, Lathes, Milling machines, Grinders, Spark machines, Vacuum mold machines, SLM 3D Printers, SLA 3D Printers, SLS 3D Printers and other peripheral equipment precision equipment 127 sets, With 3 wholly-owned manufacturing factories, Is a production enterprise specializing in precision processing of rapid prototyping handboard models.

Our engineering and sales teams will provide one-on-one quote support for your project. Typically, for similar parts, CNC lathes cost 15% less to machine than standard 3-axis CNC milling. In contrast, the cost of 5-axis machining increases, continuous 5-axis CNC milling typically costs over 20% higher than an indexed 5-axis machine (also referred to as 3+2 milling), and about double that of a standard 3-axis mill. To achieve the most cost-effective CNC machined parts, larger production runs are recommended to spread the cost of machine setup.

SLM Metal 3D Printer Maximum Printing Size: 1530×1530×1650mm

Worktable Diameter Φ400 mm. All can be processed, and larger sizes can also be consulted by engineers

The reasons for selecting SLM (Selective Laser Melting) metal 3D printing lie in its unique technical advantages and broad application scenarios. Below is a professional explanation:

SLM technology melts metal powder layer by layer using a laser, enabling the direct production of complex metal parts. Compared to traditional manufacturing methods, SLM can fabricate intricate geometries such as internal cavities, lattice structures, and flow channels, which are crucial in aerospace, medical, and automotive fields. Additionally, its precision can reach the micron level, meeting the demands of high-accuracy parts.

SLM technology employs layer-by-layer melting, resulting in minimal material waste compared to subtractive manufacturing. Unused metal powder can be recycled, significantly reducing production costs. This advantage is particularly notable when working with expensive materials such as titanium alloys, aluminum alloys, and stainless steel.

SLM metal 3D printing eliminates the need for molds, enabling the swift transition from design to final product. This significantly shortens development cycles, providing greater flexibility, especially during iterative design and testing phases.

Parts manufactured with SLM can achieve a density of over 99%, with mechanical properties that are on par with or superior to traditionally forged parts. Combined with a variety of alloy powders (e.g., titanium alloys, nickel-based alloys), SLM components excel in strength, hardness, and corrosion resistance, making them ideal for high-performance applications.

In traditional processes, manufacturing complex parts often requires multiple steps and tools. SLM can complete production on a single machine, significantly reducing the need for expensive fixtures and the coordination of multiple devices. This makes SLM particularly suitable for customized, small-batch, high-precision production, offering exceptional cost-effectiveness.

SLM technology aligns with modern industry’s pursuit of green manufacturing. Its low material waste, high resource utilization, and reduced carbon emissions make it a vital technology for sustainable development in manufacturing.

In conclusion, SLM metal 3D printing stands out as an ideal choice for precision processing due to its high precision, efficiency, adaptability, and superior material performance, helping businesses gain significant advantages in competitive markets.

The surface finish of parts produced by SLM (Selective Laser Melting) metal 3D printing is a critical consideration for engineers and manufacturers. While SLM is renowned for its ability to produce complex geometries and high-strength metal components, the as-printed surface finish typically has a distinct texture due to the inherent characteristics of the process. Below is a professional explanation of the factors influencing the surface finish, its characteristics, and options for improvement.

The as-printed surface finish of SLM parts is generally rougher compared to components produced by traditional manufacturing methods like CNC machining. This roughness is caused by several factors:

Several variables in the SLM process impact surface finish:

To meet aesthetic or functional requirements, post-processing is often applied to SLM parts. Common methods include:

The choice of surface finish improvement depends on the application. For internal channels or hard-to-reach areas, abrasive flow machining or chemical polishing might be ideal. For components where mechanical performance is critical, machining may be combined with polishing to ensure smooth surfaces and optimal functionality.

In summary, while the as-printed surface finish of SLM parts has a characteristic rough texture, it can be tailored through process optimization and post-processing to meet stringent industrial requirements, balancing aesthetics, functionality, and cost-effectiveness.

Impressed by the fast delivery and top-quality 3D Printing parts! Your team's efficiency and personalized service were outstanding. Excited for future collaborations!