The Rise of the 1000mm 3D Printer Revolution: Unlocking unprecedented manufacturing freedom

The world of additive manufacturing is undergoing an earthquake shift. Over the years, the size limitations of conventional 3D printers have downgraded the technology to prototype smaller components or complex detailed parts. Although this limitation is invaluable for a particular application, it hinders its potential to revolutionize mass production and end-use parts manufacturing. enter 1000mm 3D printer revolution – Advances that change the size of the game, destroying the barriers to scale. These industrial behemoths, with one cubic meter (1000mm x 1000mm x 1000mm) or even greater build volumes, fundamentally redefine the possibilities in design, prototyping and production.

Why is the 1000mm transformative function

The build volume of 1000mm is not only linearly expanded; this is a paradigm shift that enables completely new possibilities:

- Integration: Instead of designing complex structures into multiple smaller components that have to be hard-pressed (introducing potential points of failure and alignment issues), it is now possible to print entire functional components or large monolithic parts in a single run. Think of a considerable sizeable aerospace house, car chassis parts or architectural elements.

- Most delivery times are reduced: Traditional methods such as CNC machining or casting large components involve multiple settings, a wide range of tools and lengthy machining times. Large additive manufacturing industries have significantly cut these lead times, accelerating product development cycles and time to market. Now it can be achieved in a few days for weeks or months.

- Design free release: The limitations of subtraction manufacturing are fundamentally gone. Engineers can take advantage of composites, organic geometry optimized for weight loss, fluid dynamics or thermal management without worrying about tool path access or welding seams. Even on a large scale, internal channels, lattice structures and topological optimization forms become practical.

- Tools and Mold Revolution: Traditionally, creating a large number of tools, fixtures, fixtures, and molds is expensive and slow. 1000mm 3D printers can quickly produce these basic manufacturing aids, often with improved performance characteristics such as conformal cooling channels, which greatly reduce cycle time in injection molding.

- Small body/most economic production: For industries that require large but low-volume parts (e.g., aerospace, defense, energy), additive manufacturing at this scale is economically feasible, bypassing the massive upfront costs of traditional tools.

Overcoming the Giant’s Challenge: Large-scale Accuracy

Large-scale printing is not without obstacles. Successful printing on 1000 mm volume requires complex solutions to maintain precision, structural integrity and surface quality:

- Thermal management: Preventing uneven thermal gradients during printing (especially the key in metals) is critical to avoiding warping, rupture and residual stress. Advanced closed-loop thermal control systems and optimized scanning strategies are crucial.

- Mechanical stability: The printer frame itself must be very rigid to maintain the positional accuracy of its entire huge envelope, eliminating vibrations even in high-speed laser motion.

- Material consistency: Ensuring uniform material properties throughout a large build requires accurate powder distribution (in SLM), consistent laser power density, and inert atmosphere integrity throughout the chamber.

- Process control and monitoring: Complex in-situ process monitoring (e.g., melt pool monitoring, layer imaging) is for real-time detection and compensation of potential defects in such an important construction.

- Post-processing integration: Processing, reducing, stress relief, heat handling and finishing large parts requires dedicated equipment and expertise to seamlessly integrate with the printing process.

Great Advantage: Mastering Giant Scale

This is where Greatlight rises to the forefront of the 1000mm revolution. As a professional rapid prototyping manufacturer with extensive expertise, we have more than just large printers. We master the entire ecosystem required for successful large-scale additive manufacturing.

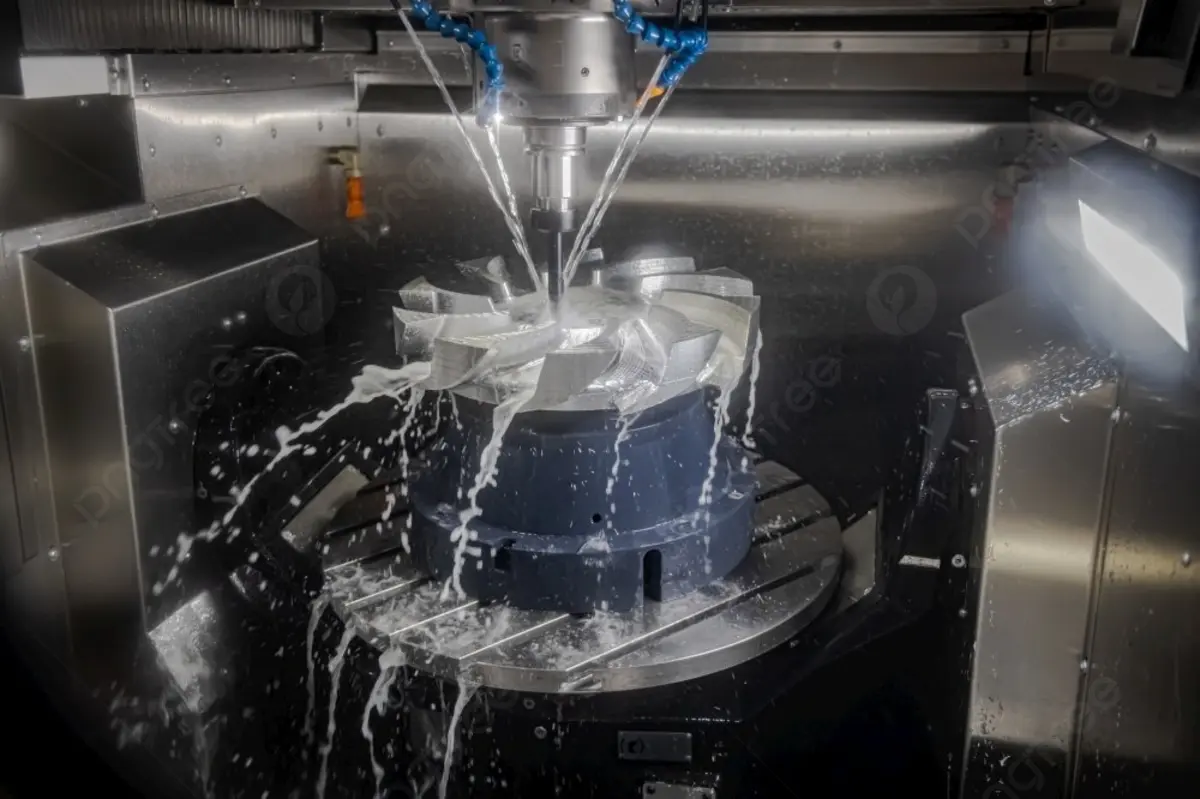

- Advanced SLM technology: At our core, we deploy the cutting-edge Selective laser melting (SLM) machine. These systems utilize high-power lasers to selectively fuse high-quality metal powder layer by layer, resulting in a completely dense, high-strength metal parts traditionally manufactured components. Our advanced SLM devices are specially designed to meet the needs of 1000mm volume to ensure stability, accuracy and repeatability.

- End-to-end solution provider: Gregtime is more than just a printer. We provide a Comprehensive one-stop serviceseamlessly manage your project from the initial CAD model to the final production-ready part:

- Expert DFAM consultation: Our team works with you to optimize additive manufacturing designs at scale to maximize profits and printability.

- Material expertise: We use a wide range of high-performance metal alloys (aluminum, titanium, stainless steel, inconel, tool steel, copper) and can support customized material requests for professional applications. "Most materials can be quickly customized and handled."

- Precision post-processing: Recognizing that prints are just the beginning, we offer integrated finishing services including CNC machining, heat treatment, relief, stress relief, hip joints), surface finishes (processing, grinding, polishing, polishing, blasting), EDM and inspection (CMM, CMM, CT-SCANNING). This ensures that dimensional accuracy and final mass quality meet the strictest tolerances.

- Quick turnaround: Enable with streamlined process and industrial scale equipment "Fast" Even for large, complex components, it can speed up your innovation cycle.

- Solve complex rapid prototype problems: Our expertise is to deal with the most difficult rapid prototyping challenges, especially large, complex metal parts. We combine technical strength with in-depth process understanding into "Professional dissolution[e] Rapid prototyping of metal parts."

The industry has changed

The impact of accessible 1000mm 3D printing spans key departments:

- Aerospace and Defense: Large engine components (shell, combustion chamber), complex structural brackets, lightweight satellite parts and tools for composite coloring.

- Cars and Motorsports: Prototype chassis components, large tools, molds (including conformal cooling), end-use structural parts, custom brackets.

- Energy and Turbo Machinery: Large turbine blades, segments, casings, heat exchangers, and oil and gas components that require corrosion resistance and high strength.

- Industrial Machinery: Large robotic arms, pump housing, specialized fixtures and fixtures for large components.

- Architecture and Architecture: Structural nodes, custom architectural elements, functional prototypes for custom templates and tools.

- Tools and molding: Large-scale injection molds, mold molds and composite tools have integrated conformal cooling channels to greatly improve cycle time.

Conclusion: The future is very big, integration and additives

The emergence of reliable, precise 1000mm metal 3D printers marks a critical moment in industrial manufacturing. It goes beyond the limitations of the past, allowing for the creation of large, complex, high-performance components that were previously impossible, impractical, or overly expensive conventional approaches. The ability to consolidate components, embrace radical design freedom and accelerate production schedules unlocks immense value.

Greglight stands on the vanguard of this revolution. Through our commitment to industry-leading SLM equipment, deep materials science expertise, seamless end-to-end services including critical post-processing, and a customer-centric approach dedicated to solving complex prototype challenges, we empower innovators and manufacturers to embrace this new paradigm.

If your project requires uncompromising scale, without the complexity of the franchise, and speed without sacrificing quality, the era of large metal 3D printing is here. Gregtime is your partner to navigate this transformative landscape. Customize your precision fast prototyping parts now at the best prices!

FAQ – 1000mm 3D Printing Revolution and Greatlime

Q1: What parts can I actually create with a 1000mm 3D printer?

A1: There is almost nothing inside a 1 meter cubic envelope! This includes: large structural aerospace components, automatic chassis prototypes, turbine housings for energy, end-use industrial tooling/jigs/fixtures, injection molds and dies (including large-scale), architectural models/art pieces, functionally integrated assemblies that replace multi-part welded structures, heat exchanges, and bespoke large-format mechanical parts.

Question 2: How does Greatlight ensure the quality and accuracy of such a large printed metal parts?

A2: Quality assurance is multifaceted:

- Advanced equipment: We use high-precision industrial SLM printers designed specifically for a large number of stability.

- Process Monitoring: The in-situ monitoring system tracks melt pool and layer mass during printing.

- Material Control: Strict powder handling protocols ensure material consistency.

- Expertise on large printing parameters: Optimized scan mode and thermal management strategies can prevent warp lines.

- Comprehensive post-processing: Stress relief, precise CNC machining and rigorous inspection (CMM, CT scan if necessary) ensure dimensional accuracy and metallurgical characteristics meet specifications.

Q3: Which materials can be 3D printed at a ratio of 1000mm?

A3: We primarily specialize in metals: Aluminum alloys (like AlSi10Mg, Scalmalloy), Titanium Alloys (Ti6Al4V), Stainless Steels (316L, 17-4PH, 15-5PH), Nickel-based superalloys (Inconel 625, Inconel 718), Tool Steels (H13, Maraging Steel), and Copper alloys. "Most materials can be customized" When discussing specific project requirements.

Q4: How "Rapidly" Is it a rapid prototype turnover for large parts?

A4: And "Rapidly" For large, high-quality metal parts, our process optimizes the speed much faster than traditional large-scale manufacturing (forging, casting, extensive machining). Turnover depends to a large extent on the part size, complexity, material and required post-processing. We prioritize efficiency and provide a clear timeline in advance. Contact us for specific project estimates and use our experience "Fast" Customize and process.

Q5: Do you really handle all the required post-processing? What functions do you have?

A5: Absolute. Great offers a real One-stop solution:

- Support deletion

- Stress relief/heat treatment (annealing, solution treatment and aging, hips)

- Hot isostatic pressure (buttocks) to reduce porosity

- Accurate CNC machining (for final net shape and tolerance)

- Surface finishing: grinding, polishing, beads/sand explosion, shooting

- EDM (wire EDM and receiver EDM) for more complex details

- Inspection and Verification: CMM, Visual Inspection, Non-Destructive Test (as needed). This integration simplifies production and ensures consistency in quality.

Question 6: Why would I choose Greatlight instead of other rapid prototyping services for large metal printing?

A6: Gremight offers a unique combination:

- Specialization in large format: We focus on solving challenges for large parts.

- Advanced SLM core technology: Provide high density high strength metal parts.

- Proven end-to-end expertise: From expert DFAM consulting firms to complex printing to careful completion and inspection – "Professionally solve the problem of rapid prototyping of metal parts."

- Materials and custom flexibility: Tailor-made solutions for unique requirements.

- Competitive value: Provide high-quality industrial AM solutions "The best price"balance investment and innovation returns.

We are recognized "One of the best rapid prototype companies from China," Dedicated to making your ambitious projects come true at scale. Customize your precision parts now!