Like the official TCT asia cooperative media exhibition,3D printing resources libraryWe will continue to broadcast the entire coverage live on the exhibition site, offering you an immersive online online experience from the first point of view, so that viewers who cannot visit the scene can also understand the dynamics of the exhibition, innovative technologies and real -time popular products.

Stay listening, we will bring a more in -depth analysis and exclusive reports during the exhibition!

At the same time, we have carefully set the official information published by the main manufacturers.Overview of the protruding facts of this exhibitionHelp everyone enter the TCT Asia 2025 exposure in advanceKey exhibitions and technical trendsQuickly find the products you need to help you look at the exhibition effectively.

First of all, let’s see what is worth paying attention to3D print equipment. Here we will classify them according to the consumer public processes.

1. Founding of the cast deposit (FDM)

The speed greater than consumers and the multicolored have become standard, the next step is artificial intelligence

In 2025, 3D high -quality 3D printers fully entered the 2.0 era, and technological innovation entered a new step.

If someone always uses “the printing speed xxx times faster than the previous generation” as a marketing sales argument, it seems a bit innovative. In addition, if a manufacturer has not so far launched multicolored printers, this can be disadvantaged in increasingly ferocious competition. It is reported that Tuozhu, Chuangxiang 3D, Zongwei Cube and Magic Technology are already selling multicolored 3D printers, and Flash Casting, Prosen and Yuntu Chuangzhi are also about to launch new multicolored printing products.

At the TCT Asia exhibition this year,Three -dimensional creative(Boom number: 8.1 / 8E75) not only will bring the K2 combo plus the most sold K2 combo, but also the first exhibition of the affordable multicolored hi printer creation combo.Flash molding(Boom number: 8.1 / 8E10) In addition to continuing to present its flagship product from the farm, the new AD5X multicolored 3D printer will also be launched.

It should be mentioned thatHave the cool(Boom number: 8.1 / 8E30) This time, the new FDM product, Centauri Carbon, will also be launched. Although it is not a multicolored model, as a first high-speed corexy 3D printer, it is also a self-old. There are also iterative productsQIDI technology(Boom number: 8.1 / 8C16), its new QIDI Plus4 also deserves to be paid attention.

What is the development management of new generation technology for 3D -quality 3D printing?

I thinkArtificial Intelligence (AI)It is undoubtedly a tendency to pay attention. Currently, we have seen that it is only by entering text or images that we can generate 3D models with one click. The Makerworld, a subsidiary of Tuozhu, and the long cube -dimension makeronline, integrated this modeling function assisted by the AI. However, there are still many places that can still be autonomous via AI, including intelligent slicing, automatic error correction, material management, etc.

Industrial grade – Continue to find applications that replace traditional manufacturing

In the field of industrial 3D FDM printing, technological development always revolves around how to replace traditional manufacturing methods in specific application scenarios. Companies constantly optimize the processes, materials and production processes to meet the needs of various industries for high -resistance, high precision, low cost and lots production. Among them, “demanding the quantity or requiring the price” can be a question that manufacturers must think carefully. For many final companies, high equipment costs remain a major obstacle to their request.

Back to this exhibition, it is not difficult to see that foreign exhibitors have rarely seen them. One of the important reasons is that the relatively high price of imported equipment has made them lose their advantage in competition from the domestic market. During the economic slowdown period, we cannot hope to return to the past and “place an order for half a year”, but we should think about how to survive the “price” cycle “involved”.

On the industrial market, we will inaugurate new faces. In,Aplas(Arrow number: 8.1 / 8:90) closed its beginnings as a startup and will bring its new FFF 2.0 product from start to finish – the Blast X.

Extend the domestic market moreSuwei technology(8.1 / 8A22) will continue to participate in the exhibition this year and will bring improved high -speed machines such as the D1000 HS and D600 Pro2 HS. The launch of these new products also means that most industrial quality 3D printers have carried out a self-briopage speed. Likewise, we will meet old friends who have always been activeYuanzhu intelligent(Boom number: 8.1 / 8F83) andIntelligence of Yimai(Boom number: 8.1 / 8E66).

In addition to the joint industrial quality FDM printers, we will see more and more in this exhibition.FGF (manufacturing of modified particles) 3D printer. Due to the drop in material costs, the largest printing size and higher production efficiency, the FGF applications market continues to grow and demand on the market, including sculptures, bathrooms, furniture and other markets increases day by day.

Gold and three -dimensional stone(Arrow number: 7.1 / 7q15) will again be unveiled with its 3D printer of mature particle FGF-1800. It is understood that the cumulative sales of this device exceeded 100 million yuan, which is undoubtedly an enviable number.

Another manufacturer focusing on 3D printing of particles isLingke Huichuang(Boom number: 8.1 / 8B56), this time, they brought the FGF1500, which is also a machine per meter level. If you want an office level device, you can consider itGreat(8.1 / 8B64)Three -dimensional creative(Boom number: 8.1 / 8E75) G5 Ultra. Axis 4 CI uni-print is a 3D printer of super anticipated quad-axis particle, which is rare on the market.

This should be mentioned as a giant in injection molding machinesAbolgo(Boom number: 8.1 / 8A08) will also be displayed again FreeFormum based on molding technology without plastic mold, which is also printed with particles in the form of raw materials.

Then take a look3D printing in continuous fiberExcept for the familiar3D aneso(Boom number: 8.1 / 8A16),Collaborative high-technology(Boom number: 8.1 / 8C20) andThree -dimensional(Boom number: 8.1 / 8F12) In addition to continuing to participate in the exhibition, this exhibition will also inaugurate a new faceNanjing Yangtze Industrial Technology Research Institute Company(Boom number: 8.1 / 8D30) andTidimensional average fiber(Boom number: 8.1 / 8J24).

Among them, the continuous fiber 3D printer launched by the Institute of Technology has a maximum molding size of 1 cubic meter. In addition, we have also found different products based on extrusion 3D print technology.

These includeAdditive Liwan(Shell numberNanchang Innovation Institute of the University of Beijing(Boom number: 8.1 / 8C103) 3D printer for the functional material of extruded gradient,Three -dimensional ceramics(Boom number: 8.1 / 8A52) The integrated multi-process 3D printer (ceramic and printable metals), as well as printable ceramics and metals), as well asForestry(Boom number: 8.1 / 8E104) Autobio Ink Direct Writing 3D Printer Series.

2. Photocury 3D printer

Compared to 3D FDM printers, 3D optical hardening printers can achieve higher printing precision. This is mainly due to the use of liquid photosensitive resins as printing materials by photocurage technologies (such as SLA, DLP and LCD) and cure them the layer by layer per layer by layer, making the print layer, thinner, finer details and smooth surface quality.

2.1 – 3D printer LCD photocide

The 3D 3D printing LCD is a 3D printing technology that uses the display screen for liquid crystals (LCD) as a light source and uses ultraviolet light to heal and shape the layer of photosensitive resin by layer. Compared to SLA (Laser harvesting) and DLP (LOCS treatment) technologies (LCD 3D 3D printers are relatively low in manufacturing costs, they were therefore very popular on the consumption market and certain professional applications.

Today, LCD 3D printing technology has entered the 2.0 era, and the devices have become smarter and easier to use. The traditional 3D LCD printer has not only an automatic level in one click and automatic transfer functions of materials and withdrawal, but also incorporates advanced features such as integrated heating, air purifier, intelligent detection of foreign objects and printing failure detection. Even users can remotely monitor the printing process via the application at any time, considerably improving the convenience of use and printing the success rate.

Machines that are worth lending to includeHave the cool(Boom number: 8.1 / 8E30) Saturn 4 Ultra 16K,Prosan(8.1 / 8J57) Mighty Revo 10.1. In addition to basic equipment, there are also new 3D printing printers of professional quality.

For example:Smart rhsae(Boom number: 8.1 / 8F36) 3D 3D printer dental tips,HimalayasLarge Him-D300a size with stand number: 8.1 / 8D70, andAsahi and Sheng(Boom number: 8.1 / 8D78) MOBIUS3DP, a high speed high speed 3D printer.

2.2 – 3D printer DLP photocide

DLP 3D printing uses digital light treatment technology, and the main difference between IT and LCD 3D printing is the light source. DLP uses a digital projector to directly project UV light, while LCD 3D printing is based on a liquid crystal screen (LCD) as light source for clear shade imaging.

Now at TCT Asia exhibition,Fuzhi technologyIn addition to the DF2 + improved by Pull-Up with the stand number: 8.1 / 8E36), we will see more from the DLP 3D printer to flow. Among them, includingVertical and horizontal additives(Boom number: 8.1 / 8C78),Miracle intelligence(Boom number: 8.1 / 8A50) and startupsIntelligent Hengjia(Boom number: 8.1 / 8N55) and other products will be launched.

In addition to the conventional DLP3D printers, high-precision 3D printing micro-nano has also attracted more and more companies to participate. In addition to Xingsheng Precision that we have previously reported, we will also see the TCT Asia exhibition this yearMofang accuracy(Boom number: 8.1 / 8A05) andPrison(Boom number: 8.1 / 8E95) New 3D micro-nano printers are displayed on the site.

2.3 – SLA Photocury 3D printer

SLA Photociur 3D printing technology is mainly based on the ultraviolet laser as a light source and accurately controlling the laser stain scan through the galvanometer system. The obvious difference here is LCD and DLP 3D printing in that SLA uses a point -by -point scan and hardening, while the LCD screen and the DLP are exposed to cure the entire layer simultaneously in the form of surfaces. Therefore, the SLA 3D printing is slower to print, but it has higher printing precision.

In the past, we have usually called LIANTAI technology, JINSHI 3D technology and ZHONGRUI The three giants in the 3D SLA printer industry. But now, these three companies have shown obvious differentiated arrangements in their product ranges, and ALs is only one of its many technologies.

To this exhibition,LIANTAI technology(Boom number: 7.1 / 7F50) will launch a new 3D printer for tire molds – RA900. This device is designed for mass production of tire molds and provides effective and precise printing solutions. Also,Aurora Innovation(Arrow number: 8.1 / 8F24) will display its SLA 3D Pull -Up – SLA2040 printer, which uses linear laser scanning technology, which is also worth it.

In addition to the 3D photocurage printers common above, we will also seeBoli technology(Arrow number: 8.1 / 8D20) 3D HALS Ultra-High Speed printer launched for 3D shoe printing,3D systems(Boom number: 8.1 / 8A20) 3D 3D 3D 3D 3D printer specially designed for the jewelry industry,Flash casting technology(Boom number: 8.1 / 8E10) 3D 3D color printer in office CJ270, as well as3D Sené(Boom number: 8.1 / 8F50) has a new model upgraded for the 3D color portrait printer.

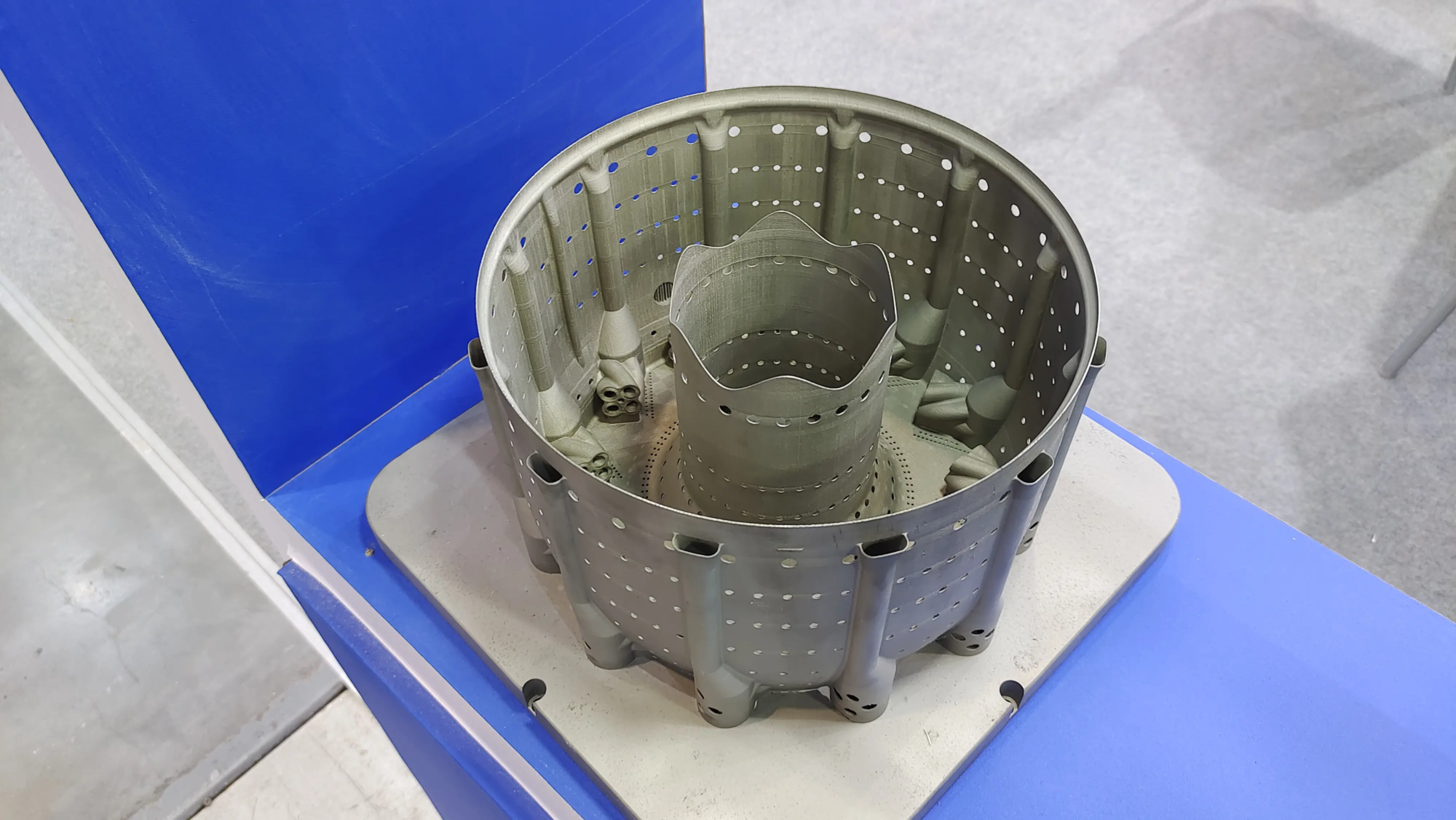

3. 3D metal printer

3.1 – Selected Laser Felting (SLM) – “Large and complete, small and beautiful” parallel

SLM 3D printers occupy an absolute basic position in the field of metallic 3D printing technology, and their applications gradually extend from traditional high -end manufacturing areas such as aerospace to a larger consumption market such as molds and 3C electronics. In recent years, “laser war” within the industry has become increasingly fierce, and the main leading companies have increased their investment in several laser technologies to continuously improve the efficiency of printing and the quality of molding.

In,Platinum(Boom number: 7.1 / 7F15) BLT-S825 has a size of 850 × 850 × 2500 mm and adopts a 24-light system;Huashu hi-tech(Boom number: 7.1 / 7F05) The FS1521M-U has a forming size of 1510 × 1510 × 1650 mm and 500 W × 16/32 fiber laser is available;Avic MAIT(Arrow number: 7.1 / 7k15) The MT800H is delivered with 10 laser standards, with a format of forming 832 × 832 × 1500 mm. In addition to large SLM equipment, these manufacturers have revealed that they will also publish a number of new products.

In addition to certain companies focusing on “large” equipment, some companies focus on the side of the market segment side.Bikosu-Soku(Arrow number: 8.1 / 8C05) Deskfab X1, a 3D printe printer in integrated metal quality desk designed for general dental clinics. Also,Tianhong laser(Arrow number: 8.1 / 8C30) will bring Th-S400, a 3D metal mold with ultra-fine shoe mold;XIHE Additive(Boom number: 7.1 / 7k05) M350G, a 3D printer in pure green laser and copper;Ruitong additive(Arrow number: 8.1 / 8C75) METAL Office grade 3D Printer MLAB.

It should be mentioned thatYingchuang Aurora(Boom number: 7.1 / 7F67) will participate in the exhibition for the first time, which is also the first local metal printing company in Henan. Also,Gathering(Boom number: 7.1 / 7Q30) will also be unveiled as a manufacturer of equipment, bringing a variety of 3D SLM Metal printers.

3.2 – Direct energy deposit (DED) – more profitable metal printing

Direct energy deposit (DED) is a technology that uses laser, plasma, electron beam and other heat sources to melt the metal materials (powder or wire) to obtain layer printing by layer. It is mainly used in the manufacture of large metal components. This technology has the advantages of rapid printing speed, high mechanical resistance and good structural integrity. It is widely used in aerospace, the manufacture of ships, heavy equipment and other fields.

Rongsu technology(Boom number: 7.1 / 7D50) released the new L1 Lite, the Laser directional energy deposit (L-DED), and will provide a multi-laser coaxial wire supply device. Also,Seiken’s wisdom(BOOM n ° 7.1 / 7F66) Although the electrical energy deposit equipment of the electron beam (EBAM) is not directly displayed, representative printed samples, including titanium alloys, will be presented. AndYougu Zhimeng(Boom number: 7.1 / 7E68) will bring a brand new plasma arc wire device (WPAAM); If you are interested in the manufacture of an arc additive (waam), you can continue to be carefulInnigma(Boom number: 7.1 / 7D26).

3.3 – Metal adhesive spray (MBJ) – more suited to mass production metal printing

Adhesive spray The powdered material is linked to the shape by spraying the adhesive layer by layer until the end of the final room. It is suitable for a variety of materials such as metals, ceramics and sand. Metal adhesive spraying is metal powder, unlike other metallic 3D printing processes, which do not require any additional support structure, which makes it more suitable for the manufacture of products with complex shapes and fine details.

Deyiwei(Boom number: 7.1 / 7K65) will present its hundreds of 3D jet 3D jet printing device, its workshop system and a medium -sized device, X25Pro.Electronics Rongyue(Boom number: 8.1 / 8A01) 3D-BJ metal printers suitable for scientific research will be launched directly. As before,Hp(Boom number: 8.1 / 8E36) will continue to present the results of the case of its metal jet technology, although we are still looking forward to seeing its Jet S100 metal beginnings.

Compared to metal materials, 3D printing costs of the sand type adhesive are lower. This exhibition will also take placeShared intelligent equipment(Boom number: 7.1 / 7A15) The first new product casting sand 3D printing equipment AJS 1250, andKangshuo group(Boom number: 8.1 / 8F30) High -speed printing equipment KSS1800B Sand 3D provides effective solutions for the casting industry.

In addition to traditional 3D metal printers above, we will also seeGold and three -dimensional stone(Boom number: 7.1 / 7q15) 3D liaison printer with five MUF-1060 axes, andAerospace engineering equipment(Arrow number: 7.1 / 7K30) The 3D drop -down deposit printer with developed friction shows a diversified innovation in the manufacturing technology of metal additives.

4. 3D nylon printer

Although some FDM 3D printers can also print nylon materials, we mainly take selective laser sintering technology (SLS) as an example. Similar to SLM, SLS also uses laser as a light source, but laser power is required, and commonly used materials include polymer powders such as nylon.

In the past, with regard to 3D SLS printers, the first thing that comes to mind can beHuashu hi-tech(Boom number: 7.1 / 7F05) andThree -dimensional yingpu(Boom number: 8.1 / 8D10). However, as more and more manufacturers are entering the market, market choices have become more abundant and the prices of the equipment have gradually decreased in competition.Vertical and horizontal additives(Boom number: 8.1 / 8C78) Previously, it has become famous in industry with its profitable SLS equipment. After SLS2030 from last year, this time he brought an SLS-1518 of smaller industrial quality.

Gold and three -dimensional stone(Boom number: 7.1 / 7q15) also provides its own P260 printer in 3D nylon. The device has high integration, no auxiliary machine is required and it has an advantage of the price while retaining stable performance. Also,Fuzhi technology(Boom number: 8.1 / 8E36) also continues to extend its product range. According to examples of photos published by his official account, it is visually believed that he should also be nylon sintering equipment.

After introducing the equipment, we will focus on the development and innovation of 3D printing materials. The advancement of materials not only promotes the improvement of printing performance, but also widens the areas for applying additive manufacturing. Let’s see what the new materials deserve to be ready to pay attention to this exhibition.

1. Wire

In the past, one of the problems that we have always “complained” is that the materials are too fragile and that the finished product will be broken as soon as it is abandoned. This not only affects the practicality of printing, but also considerably weakening the enthusiasm of users for the purchase of equipment. With the advancement of material technology, such as the introduction of an improved APL, impact resistant ABS, flexible composite materials, etc., this problem is gradually improving. In addition, engineering materials receive more and more attention, which will also become a major trend in 2025.

According to previous reports, Tuozhu will soon launch professional quality equipment, and the materials used will be ASA, PA, PPS, PETG carbon fiber, PPS-CF and other special functional materials. Nowadays, manufacturers of materials make arrangements in advance will also contribute to making complete preparations before the explosion of market demand.

existThree Greens(Bouchette number: 8.1 / 8E55), we will see engineering materials such as PA12-CF, PEEK, PA6-GF;Polymaker(Boom number: 8.1 / 8E50) Two composite carbon fiber wires will also be launched-Fiberon ™ Pet-CF17 and Fiberon ™ PPS-CF10;AlicePA-CF and PPS-CF of (Stand number: 8.1 / 8D61) are also developed for industrialization scenarios.

As a leading business in 3D printing materials,Esun Easy to Live(Boom number: 8.1 / 8C50) In addition to providing engineering materials, new PLA / PET transparent materials and PLA photovariable materials will be brought to further enrich the selection of materials. If you are looking for plans rainbow, tricolor or bright plain, you can followYuanjia biologyStand (Boo number: 8.1 / 8D50).

If you need FGF special granules, you might as well go thereOrganic haizheng(Boom number: 8.1 / 8B61),Jufeng New materials(Boom number: 8.1 / 8C83) orPulis(Bouchette number: 8.1 / 8C82) Take a look at the stand.

2. Resin

If the 3D FDM printers use wires, the 3D photo printers depend mainly on the photosensitive resin as a print material.

As a major manufacturer of resin materials,Great summary(Boom number: 8.1 / 8E64) This time, a variety of new products have been brought, including the colorless transparent resin 8001, with a light transmittance of up to 90.8%; Green Engineering Resin 8228, which supports the Auto-Tape de Goujon; And the RC600 red wax resin, which has a high -end matt texture and no reflective effect.

In the past, two components were rare, but nowMuxintong Studio(Arrow number: 8.1 / 8N60) will display the T6 T6 T6 rubber printed in 3D rubber of two groups and the polyurethane elastomer of Silicone T7 type, which can be used for soles, cushions, handles and helmet cushion applications.

In addition to displaying dental resin materials,Esun Easy to Live(Boom number: 8.1 / 8C50) The brand new W300 16K washing resin will also be launched. AndThree Greens(Arrow number: 8.1 / 8E55) provides a variety of high performance resin materials, including a flexible photosensitive resin, high -temperature resistant resin and high -speed rigid resin.

3. Powder

In the 3D printing industry, depending on the composition of materials, common powder materials mainly include metal powders and polymer powders such as nylon, which are used in the manufacture of metal additives and SLS polymer printing technology respectively. Let us take an example of metallic powder here to see what the new products deserve to be ready to pay attention to this exhibition.

As a main company of metal powder materials,Willari(Boom number: 7.1 / 7F57) will focus on the display of high temperature alloy GH4099, TI31 Titanium alloy and F30C mold steel.Zhongti New materials(Boom number: 7.1 / 7E55) will provide a highly resistance aluminum alloy, a circulating titanium alloy powder, a zirconium alloy in copper chrome and precious metal silver.You additive(Boom number: 7.1 / 7K66) will display the high temperature alloy based on nickel GH4169 and aluminum aluminum alloy.

StartupsThe age of juta(Boom number: 8.1 / 8A37) will launch the first new product in the world rae600.1 in aluminum alloy.Hebei Gaoye(Boom number: 7.1/7D63) The Nickel chrome alloy powder is launched and the Nicr component ratio is adjustable. Old companiesWeihao magnesium powder(Boom number: 7.1 / 7F74) Bring new rare land magnesium alloys Powder VW63K, andHiroka’s new ingredients(Boom n ° 8.1 / 8D05) A typical alloy of biphasic titanium α + β, the Ti-6al-4V alloy (TC4), will be displayed.

In addition to key equipment and materials, 3D printing technology also requires support for support software. In the past, the 3D printing software has always been a “gap” in China, but now the situation has improved. For example, in the field of 3D -quality 3D printing, Orcaslier occupies an important position in the FDM track, and Chitubox also has a large user base in the LCD field. In the industrial track, we have seen the rapid growth of Eater technology.

At the TCT exhibition in Asia 2025,Hexcon(Arrow number: 8.1 / 8:75) will provide simulation software for additive manufacturing process for the Sim -SuminA additive.Materialize husbands(Boom number: 8.1 / 8A10) will present the latest version of the Magics 28. AndFlow-3D China(Boom number: 8.1 / 8:78) will display Flow-3D AM software to further improve simulation and optimization of 3D printing processes.

Domestic 3D 3D printing software representingGrenade(Boom number: 8.1 / 8F78) will continue to present its additive Voxeldance 5.0, which incorporates the modeling, simulation and manufacturing functions, and the Tango Voxeldance of the DLP / LCD 3D slice software.Jin yuanming(Boom number: 8.1 / 8K67) provides control system software adapted to 3D SLM / SLA / SLS printing equipment.

And Tripo isVAST(Boom number: 8.1 / 8F116) launched a 3D model with billions of parameters, which supports a text or images input to generate 3D models. Currently, Makerworld and Makeronline have integrated this function.

If the 3D printer is the backend, then the 3D scanner is the front, responsible for obtaining high -precision three -dimensional data and providing the basis of subsequent modeling and printing.

At TCT Show, several companies in the 3D scanning industry will present their latest technologies and products. The first 3D scannerSikan technology(Boom number: 8.1 / 8E16) will bring a variety of new products, including the SMSCAN-E Smart Wiress 3D scanner.First three -dimensional arrival(Arrow number: 8.1 / 8D16) Focus on the display of the three -dimensional threadless free -speed free -speed, andPhotoelectric zhixiang(Boom number: 8.1 / 8F64) will be unveiled on the stand as an integrated Miraco Plus three -dimensional scanner.

Easy to build blocks(Boom number: 8.1 / 8F20) The Rayzoom G100 3D space scanner will inaugurate its first launch in Asia.Xunheng technology(Boom number: 8.1 / 8k85) launches the 3D Vlight scanner, andCome in high technology(Boom number: 8.1 / 8N64) brings the 3D G1Q-S smart camera, which are both the first to be launched in the world.

It should be mentioned that start-upsJet technology(Boom number: 8.1 / 8F70) A three -dimensional measurement device on AI for children’s physical parameters will be launched around the growth and development of children.Xianku Intelligent(Boom number:

8.1 / 8D116) launched the Xianku 3D intelligent foot measurement instrument and the Xianku 3D intelligent body measurement.

A 3D printer is not only an independent system, but is also based on a variety of related equipment and support installations. These include lasers, scanning galvanometers, optical machines, print heads, display screens, detection systems and post-processing devices, and they are essential for efficient and high quality 3D printing.

Galvanometers and lasers, etc.

In the 3D metal printing package,Take the laser(Boom number: 7.1 / 7D72) The ninth generation of Laser heads in coaxial and powder wire is launched for the manufacture of laser additives (WAAM).

Laser Bachenxin(Arrow number: 7.1 / 7C60) released a BFSC-500 / 4000m fiber laser with double beam.The romance of the kingdom is fierce(Boom number: 8.1 / 8C70) will display a high -power nanosecond green fiber laser, whileRing laser(Arrow number: 8.1 / 8A88) Bring the power head in light wire CH-WPC60 / powder supply head.

Also,Synchronization precision control(Boom number: 8.1 / 8k57),Site optics(Boom number: 8.1 / 8k71) andPhotoelectric Noya(Boom number: 8.1 / 8B76) and other companies will display Galvanometer systems to further improve the optical control capacities of 3D printing equipment.

Optical machine

High -tech radiation(Boom number: 8.1 / 8k66),Optics Yangming(Boom number: 8.1 / 8k88) andOptometry(Boom number: 8.1 / 8F60) Various optical machines were launched for 3D DLP optical hardening printers. In addition, includingOnly the sharp light(Boom number: 8.1 / 8N78) andGiant vida(Boom number: 8.1 / 8m45) A spying double optical machine will be launched. AndAnlum Optics(Arrow number: 8.1 / 8M62) Optical projection machine for high precision projection and the intelligent light source module will soon be launched.

Nozzles, extruders, etc.

In the 3D printing of fusion depot (FDM),Fitos(Boom number: 8.1 / 8:22) A variety of silicon, throat and extruder carbial nozzles have been launched.BIGE technology(Boom number: 8.1 / 8:66) Launched printer accessories from the Panda series developed for 3D Tuozhu printers. If you need a 3D printing consumable production line, you can follow the Flander cabin (Stand number: 8.1 / 8A45).

Post-processing

If you need a 3D printing consumable drying box, you can be carefulThree Greens(Boom number: 8.1 / 8E55) The E2 drying box launched can not only dry it, but also provides a constant temperature environment of 110 ℃ to meet professional requirements for engineering materials such as ABS, PC and nylon.

If you need a residual material residual material cleaning machine, you can check itOR technology(Boom number: 8.1 / 8N50). If a 3D printing polisher is necessary, the chemical polishing with a fluid 3D printing of the new Micronano materials (Stand number: 8.1 / 8Q65) is worth paying attention and can be used to print surface finishing treatments for plastic parts.

If you need to treat heat from printed electronic products, you can be carefulNorman Beal(Boom number: 8.1 / 8N66) Special thermal treatment Forage for 3C 3C products launched. If the residual powder should be removed,Xihao technologyThe powder cleaner with (Stand number: 8.1 / 8N75) is a good choice.

If you just want to know more about online 3D printing, the above information can already meet most of your needs. However, if you want to live and explore the endless 3D printing possibilities more deeply, you should go to the site of the exhibition in person and communicate face to face with industry experts.

In 2025, let’s meet at the TCT exhibition!

It is recommended that youComplete the reservation in advance and you are exempt from 50 posts in yuan

And save your visit confirmation letter

Time and place

March 18 09:00 a.m. – 5:30 p.m.

March 19 9:00 a.m. – 3:00 p.m.