Introduction: Embrace the speed and accuracy of modern manufacturing

In today’s highly competitive industrial landscape, the ability to iterate rapidly in the prototype directly affects the product innovation cycle. Companies need reliable partners that combine cutting-edge technology with material expertise to transform design into functional parts without delay. This is Great Good at it. As the leading rapid prototype manufacturer headquartered in China Selective laser melting (SLM) 3D printing Technology for high-precision metal prototypes and end-use parts. In addition to manufacturing, the company also offers comprehensive after-processing solutions, making it a true one-stop partner in aerospace, automotive, medical equipment, and other industries.

Why fast prototype? Strategic Advantages

Design and quality production with rapid verification form, fit and function. For engineers, this means:

- Time to accelerate to the market: Test and perfect the design in a few days rather than months.

- Reduce risks: Determine defects as soon as possible to avoid expensive revisions in the overall production process.

- Free design: It is impossible to achieve complex geometric shapes through traditional methods.

Greatlight’s expertise ensures that these advantages become a tangible reality through advanced technical capabilities and careful attention to detail.

Outstanding core advantages: Excellent engineering

1. Advanced SLM 3D printing technology

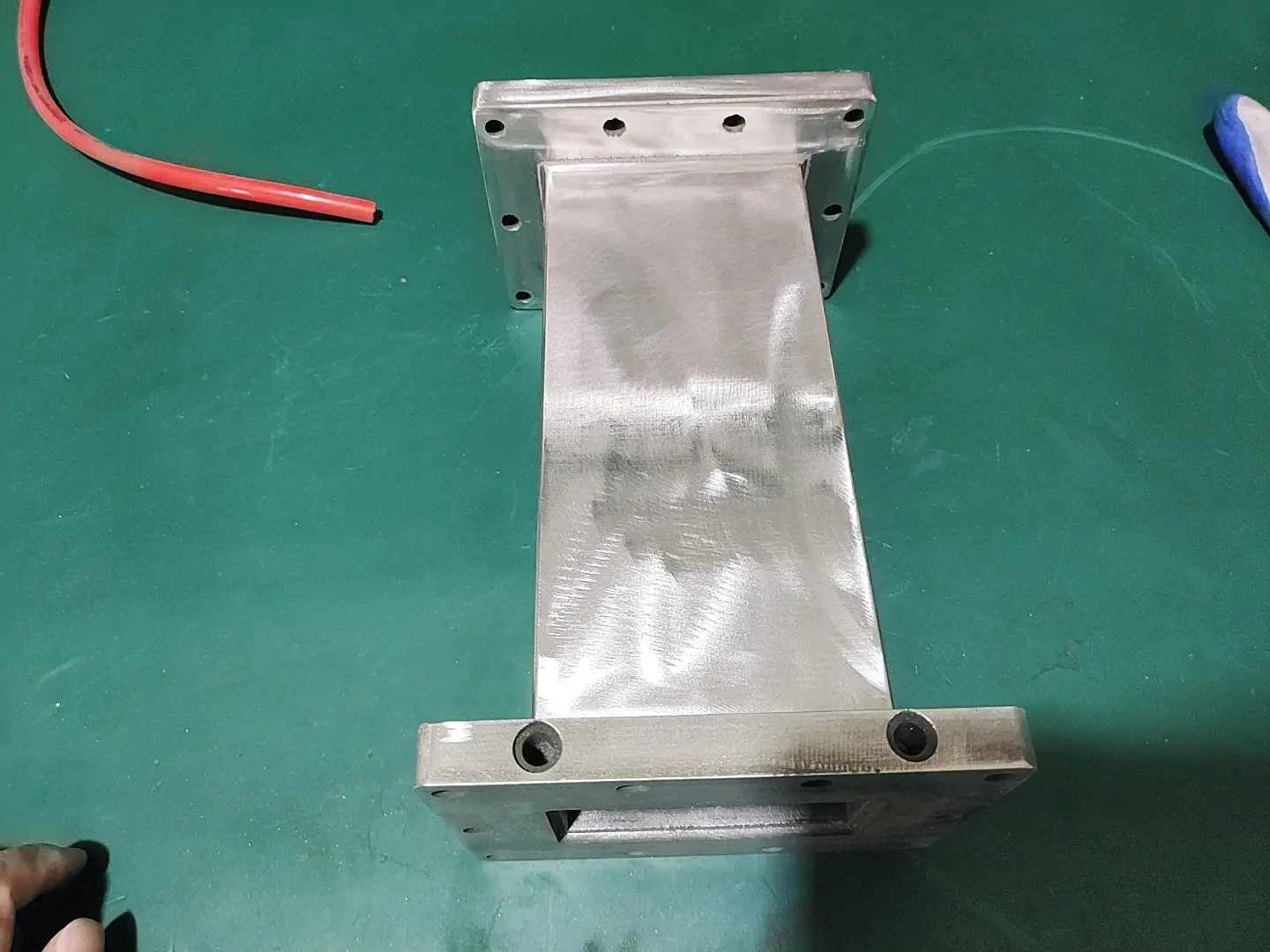

Greatlight uses industrial SLM printers equipped with multi-laser systems that can be built faster without sacrificing accuracy. Key features include:

- Material versatility: Process metals such as titanium alloy (TI6AL4V), stainless steel (316L), aluminum (ALSI10MG), nickel superalloy (Inconel) and copper.

- High density output: Use optimized laser parameters and powder metallurgy principles to achieve a density of nearly 100%.

- Microscale accuracy: Build complex channels, internal lattice and thin walls (down to 0.2 mm).

Technically rigorous: Layer resolution is up to 20μm, ensuring matching (or exceeding) the matching mechanical properties after heat treatment.

2. Integrated post-processing suite

Prototyping does not end when printing. Greglight provides the final parts by:

- Subtraction processing: CNC milling horizontal tolerance (±0.01 mm).

- Surface reinforcement: Customized finishes by shooting, polishing, bead blasting or paint (e.g., heat resistance, biocompatible).

- Thermal management: Vacuum heat treatment stress relief and optimal grain structure.

This vertical integration eliminates fragmentation of the supply chain, ensuring consistency and speed.

3. Materials Science Expertise

Greatlight works with customers to customize alloys for specialized applications:

- Medical implants: Bioente Titanium Surface.

- Aerospace components: In vitro grades with poor oxidation.

- tool: Steel mold with integrated conformal cooling.

Materials certificates (e.g., ASTM/ISO compliance) and internal metallographic testing ensure performance reliability.

4. Agile workflow and scalability

From 1 piece prototype to 500 unit batches, Greatlight’s Tech stack supports seamless scaling:

- AI-driven design analysis: Software detects stress points and optimizes support structure.

- No compromise on speed: Emergency orders to carry out key projects within 24–48 hours.

Why choose Greatlight? Quantitative difference

- Cost-efficiency: China-based manufacturing can reduce overhead without quality trade-offs (up to 40% of EU/US peers).

- Certified quality: ISO 9001 complies with material traceability and fatigue testing.

- Cross-industry authority: Verified success in NASA-inspired aerospace components, FDA cleaning surgical tools and automotive endurance parts.

- Concurrent cooperation: Engineers work with clients to perfect DFM (designed for manufacturability) and merge innovation with realism.

Conclusion: Your partner goes from prototype to production

Greglight embodies the development of rapid manufacturing: a convergence of technological maturity, material proficiency and customer-centric agility. By elevating SLM 3D printing to only produce to the overall problem-solving ecosystem, they make engineers innovate fearlessly. Whether you iterate your medical device or stress-test your turbo blades, Greatlight proves that speed, accuracy and reliability can coexist. The future of manufacturing is not only fast, but also radiant. Ready to change your mind? Work with pioneers.

FAQ: Unveiling Greatlight’s rapid prototyping service

Q1: How does SLM compare with traditional manufacturing?

SLM excels in complexity and speed. When processing materials are removed, the SLM is built layer by layer using metal powder to achieve hollow structures, weight-optimized lattice and reduced waste. The CNC process used for complex parts is usually 70% faster than the CNC process.

Q2: What metals do you deal with? Can I request a custom alloy?

We deal with common alloys such as stainless steel, titanium and aluminum, plus "Externalists" Like Inconel or Tungsten. Customized mixtures of materials (e.g., steel with extended copper) are possible – our metallurgical team reviews feasibility pre-production.

Question 3: How do you verify the quality of the parts?

Experiences per batch:

- Dimensional inspection is performed by optical scanning/CMM.

- Mechanical test (tensile strength, hardness).

- For porosity/x-ray tomography containing screening.

Includes certification test reports.

Question 4: I urgently need a prototype. What is your fastest turnover?

Basic SLM parts: 24–48 hours. Complex components with post-processing: 3-5 days. Speed up the release of fee application on the same day.

Q5: Can you handle large quantities of orders like batch production?

Absolutely. Our hybrid approach (SLM + CNC) supports low to medium volume runs at cost efficiency (up to 5,000 units per year).

Q6: Which file format do you accept?

Standard CAD format: step, IGES, STL or parasite. Our engineers evaluate productivity before citing.

Q7: Is surface roughness the focus of SLM parts?

as printed surface average RA 10–15 μm. Post-processing can achieve RA0.4μm (mirror polishing mirror) or specific textures.

Question 8: Is your prototype suitable for functional testing?

Yes. Heat-treated, fully dense SLM parts withstand operating stresses-EG, fluid pressure tests or dynamic loads. Medical/dental prototypes can achieve implant-grade biocompatibility.

Q9: Are you assisting in CAD redesign?

By DFM Consulting: We recommend optimizing overhangs, wall thickness and internal support to avoid defects or cost overruns.

Q10: What guarantee applies?

100% dimensional compliance for each specification. Material certification. Warranty for printing defects with remedial options.

Unlimited innovation. Contact Greatlight now to push your prototype into reality.