ISO 9001 Factory

ISO 9001 Factory

The world’s first CNC machining center that dares to provide free samples!

3-axis CNC machining is the best choice for a cost-effective, reliable, and simple manufacturing process.

✅ Ideal for low- to medium-complexity prototyping and low-volume production

✅ Prototype design and mass production within 3-5 days.

✅ Low cost and short delivery time are unparalleled advantages.

✅ Great Light CNC Machining ISO 9001 Certified Factory.

✅ ±0.001mm and above precision requirements can be processed.

Reduced Setup Costs: The programming and setup process is less complex, requiring fewer advanced skills and tools.

3-axis CNC Machining is generally more cost-effective than 4-axis and 5-axis CNC Machining.

With fewer axes, there is less chance of misalignment or motion-related errors during machining.

Quick Setup: The simpler work-holding and tool alignment processes mean faster machine setup.

One of the Best Rapid Prototyping Companies from China, Great Light CNC Machining Center is an ISO 9001:2015 certified manufacturer and is an excellent choice for custom metal and plastic parts. Whether you need a complex part made from a 3D design or a finished product for a high-level conference presentation, we can quickly produce prototypes and parts in a matter of days using 3 4 and 5 Axis CNC Machines.

CNC Manufacturing Experts

We use CNC to quickly process small and large-volume production orders for clients in a variety of industries: industrial design, automotive parts, robotic parts, prototypes, medical devices, aerospace, defense, electronics, hardware startups, industrial automation, machinery, marine, and more.

There is no limit on the order quantity and product value.

There are many types of materials for CNC processing. The main metal materials are: aluminum alloy, stainless steel, brass, various steels, titanium alloys, etc., which can meet the performance requirements of different materials.

One of the most important advantages of CNC prototypes is that its CNC processing accuracy is higher than other processing, and the maximum tolerance can reach ±0.001mm / 0.001 In, and multi-faceted structural products can be formed in one go.

CNC prototypes have high fidelity and high surface treatment level. After subsequent processing such as grinding, polishing, sandblasting, painting, silk screen, UV, electroplating, etc., the product effect is completely comparable to the products produced by the mold.

With years of manufacturing know-how, Great Light has covered you for CNC Machining and low-volume manufacturing.

Achieve the perfect finish with our range of surface treatments. Whether you require anodizing, plating, or painting, we ensure your parts meet both aesthetic and functional specifications.

Here’s what our satisfied customers have to say about how we met their needs, Their words speak louder than ours.

Designer

Thrilled with the fast CNC production and top-notch parts! Excellent service and flawless surface finishes. Great job!

Business Owner

The level of expertise of their engineers and their ability to complete these projects in a short period of time is commendable and worthy of recognition.

Designer

The results were outstanding. We were manufacturing a large housing component for an aerospace application with extremely complex hole geometry.

Business Owner

Had a great experience with GreatLight! Alice’s communication and dedication were excellent, and the product quality exceeded expectations. Highly recommend!

Businessman

They handled all aspects of this turnkey project quickly, professionally, and cost-effectively. We look forward to working with them again on future projects.

Business Owner

This is the most professional CNC service provider I have ever worked with and it has been a pleasure to work with them since day one. I have been in procurement for over 15 years and have worked on many projects with suppliers from all over the world.

Business Owner

I have been with them from the beginning and have seen this progress and I am very satisfied. Thanks again to all of you and everyone else behind the scenes for doing a great job.

Business Owner

Great Light can handle your CNC machining whether you need a few parts or over 10,000 end-use units. Check out the variety of custom CNC services we offer to take your designs from concept to reality quickly and accurately.

Our own internal processing capabilities: Five-Axis CNC 16 Units, Four-Axis CNC 12 Units, Three-Axis CNC 27 Units, 3 Axis CNC Mill, 3 Axis CNC Milling Machine, 3 Axis CNC Machine, 3 Axis CNC Router, 3+2 Axis CNC Machine, CNC Milling & Turning 46 Units. If you have larger processing needs, we can also meet them.

CNC 3-axis milling is a highly versatile and cost-effective manufacturing process that offers precision, reliability, and efficiency for a wide range of industries. Here’s why it stands out:

Simplicity and Accessibility

CNC 3-axis milling machines are easier to operate compared to multi-axis machines, making them ideal for beginners and cost-conscious businesses. They are widely available and offer a lower entry barrier in terms of setup, training, and maintenance.

Precision and Consistency

With computer numerical control, 3-axis milling delivers consistent, repeatable results. It excels in manufacturing components with tight tolerances and intricate 2D and 2.5D designs.

Versatility for Common Tasks

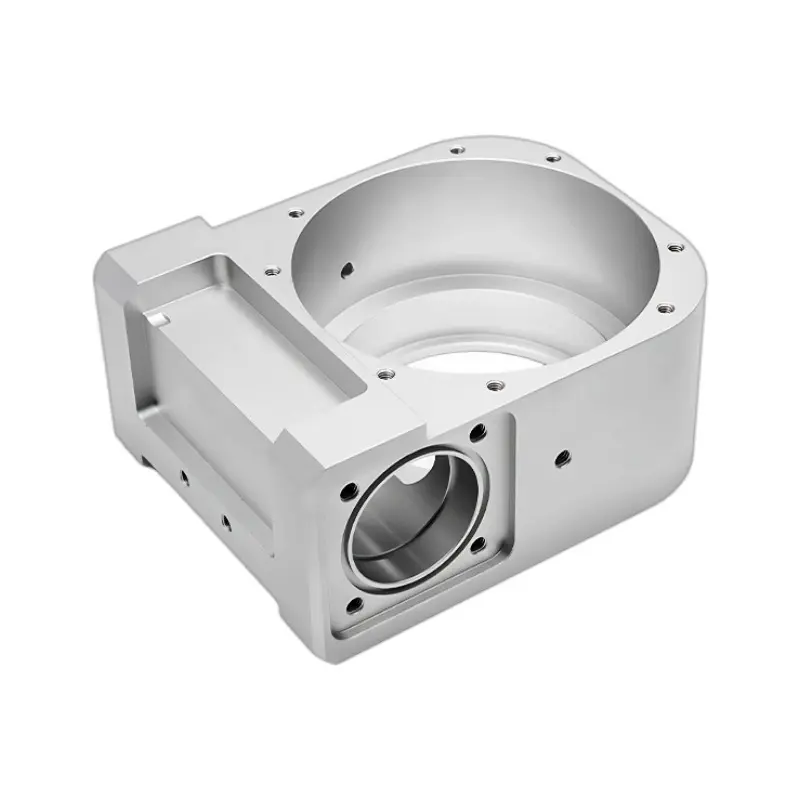

These machines can handle a variety of tasks, including drilling, contouring, slotting, and face milling. They are particularly suitable for flat or prismatic parts, such as plates, brackets, and housings.

Cost-Effectiveness

The simpler mechanical design of 3-axis machines reduces purchase, maintenance, and operating costs compared to 4-axis and 5-axis systems, making them ideal for small-to-medium production runs.

Wide Material Compatibility

CNC 3-axis milling can machine a wide range of materials, from metals (aluminum, steel, brass) to plastics and composites, catering to diverse industry requirements.

Faster Lead Times

For straightforward parts, the streamlined process of 3-axis milling allows for quicker production and shorter lead times compared to more complex machining setups.

Adaptability Across Industries

From aerospace and automotive to electronics and medical, CNC 3-axis milling is used across industries for creating high-quality components, proving its versatility and reliability.

CNC 3-axis milling is a practical choice for projects requiring precision, efficiency, and affordability without the need for the complexity of multi-axis systems.

A 3-axis CNC machine is a type of computer-controlled manufacturing equipment that uses three linear axes—X, Y, and Z—to precisely manipulate a cutting tool or workpiece for machining. It is widely used in industries for cutting, milling, drilling, and shaping materials such as metal, plastic, and wood.

Three Axes of Movement:

Simplified Control:

The machine is programmed using CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, which generates precise instructions to guide the tool along the three axes.

Applications:

Material Compatibility:

Works with a wide range of materials, including metals, plastics, composites, and even wood.

3-axis CNC machines are ideal for manufacturing flat or prismatic parts and are commonly found in small to medium-scale production environments across industries like automotive, aerospace, and electronics.

3D Printing and 3-Axis CNC Milling are two distinct manufacturing methods, each with its own strengths, applications, and workflows. Here's a comparison to understand their differences:

3D Printing:

3-Axis CNC Milling:

3D Printing:

3-Axis CNC Milling:

3D Printing:

3-Axis CNC Milling:

3D Printing:

3-Axis CNC Milling:

3D Printing:

3-Axis CNC Milling:

3D Printing:

3-Axis CNC Milling:

3D Printing:

3-Axis CNC Milling:

| Aspect | 3D Printing | 3-Axis CNC Milling |

|---|---|---|

| Method | Additive Manufacturing | Subtractive Manufacturing |

| Material | Plastics, Resins, Limited Metals | Metals, Plastics, Composites |

| Precision | Medium to High | Extremely High |

| Complexity | High for intricate designs | Medium (limited to 3 axes) |

| Speed | Slower for large parts | Faster for bulk material removal |

| Cost | Affordable for small runs | Economical for mass production |

Choose 3D Printing for innovative, complex prototypes and lightweight designs. Opt for 3-Axis CNC Milling when precision, durability, and production scalability are essential.

Here’s a breakdown of the typical components involved in a 3-Axis CNC machining quote:

Many companies offer instant or fast online quotes for 3-axis CNC machining. Examples include Xometry, Protolabs, and local CNC job shops.

By understanding these elements, you can interpret or request 3-axis CNC machining quotes more effectively, ensuring your project stays within budget and meets your specifications.

Maximum Dimensions (3-axis milling): 1500*800*300mm, 1270×508×635 (mm).

Maximum Dimensions (5-axis milling): 4000*400*150mm, 750x1150x550mm,

600*600*600mm, 500*500*450mm, 500*310*200mm,

Worktable Diameter Φ400 mm. All can be processed, and larger sizes can also be consulted by engineers

3-axis CNC machining typically leaves a surface finish that ranges from rough, with visible tool marks, to smooth and polished, depending on factors like tool selection, cutting speed, feed rate, and whether additional finishing processes such as sanding, polishing, or coating are applied.

Aluminum

Steel (Carbon and Stainless)

Brass

Copper

Titanium

Tool Steel

Alloys

ABS (Acrylonitrile Butadiene Styrene)

Polycarbonate (PC)

Nylon (Polyamide)

POM (Polyoxymethylene or Delrin)

PEEK (Polyetheretherketone)

Acrylic (PMMA)

Carbon Fiber-Reinforced Plastics (CFRP)

Glass-Fiber-Reinforced Plastics (GFRP)

Ceramics

Graphite

Foams and Wood

By understanding the material properties and aligning them with application requirements, precision 3-axis CNC machining delivers superior performance and high-quality components across industries.

3 Axis CNC machining is an excellent choice for high-volume production due to its ability to combine speed, precision, and efficiency while maintaining consistent quality. Here’s why it stands out:

Conclusion: Choosing 3 Axis CNC machining for high-volume production ensures efficient, accurate, and cost-effective manufacturing, ideal for industries requiring precision and scalability without compromising quality.

3-axis CNC machining uses advanced Computer-Aided Manufacturing (CAM) software to generate precise toolpaths. These toolpaths dictate how the cutting tool moves along the part, ensuring that every cut follows the exact contours and features defined by the design. The CAM software is capable of simulating the cutting process to refine the toolpath, ensuring the machining process accounts for every curve, hole, and feature with high precision. Complex shapes, like pockets, angles, and curves, are achievable by optimizing the toolpath and choosing the right cutting strategies.

For parts that have intricate features, 3-axis CNC machines often utilize multiple cutting operations. For instance, a component with complex contours may first go through roughing operations to remove excess material, followed by semi-finishing and finishing passes to achieve the required geometric details. The ability to use different tools (e.g., ball-nose mills for curved surfaces, flat-end mills for straight cuts) allows the machine to produce highly detailed features with great accuracy. Tool changes are automated on most CNC machines, allowing for seamless transitions between different tools optimized for different geometries.

The core strength of 3-axis CNC machining lies in its precision and repeatability. The machine follows predefined coordinates, ensuring each part is manufactured to the exact specifications, regardless of how complex the design is. With an accuracy of up to 0.001mm in some high-end machines, 3-axis CNC machining can achieve the intricate details and tight tolerances required for complex geometries. The rigid structure and high precision of the machine reduce the chances of errors, providing consistent results for both small-batch and high-volume production.

3-axis machines are capable of producing complex 2D and 3D contours, including pockets, fillets, ribs, and intricate holes. Complex geometries like these require careful control over the depth and width of each cut. Using sophisticated control algorithms, the CNC machine ensures that the cutting tool moves along the intended path to produce smooth, accurate surfaces. The ability to program the tool to move in a continuous, controlled manner allows for the production of geometries that would be very difficult or impossible with manual machining or simpler equipment.

While 3-axis CNC machining has its limitations compared to 4-axis or 5-axis systems, advanced techniques like helical interpolation, circular interpolation, and simultaneous 3D milling can be used to produce parts with highly intricate details. For example, helical milling can be employed to produce complex internal features like threads or intricate undercuts. Similarly, circular interpolation allows the machine to follow curved or circular paths, perfect for producing rounded or spherical geometries.

One of the advantages of 3-axis CNC machines is their ability to perform operations at fixed tool orientations, which helps when producing geometries that are symmetric or consist of repeating patterns. For instance, a part with radial symmetry (like gears or flanges) can be easily manufactured by ensuring the cutting tool stays at a consistent angle to the workpiece. The fixed tool position is crucial for achieving the intended shape, especially for parts with uniform, repeated features.

Modern 3-axis CNC machines, when paired with sophisticated CAM software, have the capability to mill complex 3D surfaces. This is essential for parts with sculpted or contoured surfaces, such as automotive body panels, medical implants, or intricate aerospace components. The 3-axis machine can follow the precise 3D geometry of the part, even if it includes curved or tapered features, ensuring high accuracy in the production of parts with these complex shapes.

For parts that require machining from multiple sides or angles, 3-axis CNC machining may utilize custom fixtures and repositioning strategies. Although a true 5-axis machine can continuously adjust the position of the part, a 3-axis machine can still achieve multi-sided machining by flipping or rotating the workpiece between operations. For example, machining the top and then the bottom of a complex part, or using a jig to hold the part at different angles, allows for the production of multi-faceted geometries that would otherwise require a more advanced machine.

While 3-axis machining can produce complex geometries, the finishing process plays a critical role in ensuring the accuracy and surface quality of intricate features. Post-machining operations such as sanding, polishing, and deburring ensure that the final part meets the desired specifications, especially for surfaces that require high finishes or tight tolerances. These finishing steps can smooth out small imperfections left by the roughing and semi-finishing operations, ensuring the part meets its functional requirements.

Despite its capabilities, 3-axis CNC machining does have limitations, especially when dealing with extremely complex geometries that require angles and movements beyond the range of the three primary axes. In these cases, additional considerations, such as using advanced cutting techniques or supplementing with secondary operations (like turning or wire EDM), may be required. However, with careful planning, 3-axis CNC machining can achieve high-quality results for most moderately complex parts.

In conclusion, 3-axis CNC machining can produce highly intricate and precise geometries by leveraging advanced toolpath strategies, tool changes, and precise control of the cutting process. While the machine operates on three axes, it can still achieve complex part geometries by combining advanced cutting techniques, fixture setups, and finishing operations. With its precision, accuracy, and versatility, 3-axis CNC machining remains a core technology in the manufacturing industry, particularly for applications requiring intricate but manageable part designs.

Simplicity and Cost-Effectiveness: The 3-axis CNC machine is the most basic and widely used type. It operates along three primary axes: X (horizontal), Y (vertical), and Z (depth). This simplicity leads to lower setup and operational costs, making it ideal for straightforward machining tasks.

High Precision and Repeatability: Despite its simplicity, 3-axis CNC machines are highly accurate, with precision down to 0.001 mm. This makes them suitable for producing parts with consistent quality over large production runs.

Flexibility in Material Choice: 3-axis machines are versatile and can handle a wide variety of materials, including metals, plastics, and composites. They are commonly used for milling, drilling, and basic turning operations.

Ease of Use: With fewer axes, the programming and operation are simpler compared to more advanced machines. It’s ideal for parts with relatively simple geometries and minimal complexity.

Increased Capability with Rotary Motion: In addition to the three linear axes (X, Y, Z), a 4-axis CNC machine introduces an additional rotary axis, often denoted as A-axis (rotating around the X-axis). This allows the workpiece to be rotated during machining, making it possible to access multiple sides of the part without repositioning it manually.

Efficiency in Multi-Sided Machining: A 4-axis machine can perform operations on multiple sides of a part in a single setup. This reduces the time spent on part handling and improves overall machining efficiency.

Enhanced Precision for Complex Parts: The added rotational axis allows for the machining of parts with more intricate geometries, such as components with deep or contoured features, without the need to switch fixtures. This leads to greater accuracy in machining parts that would otherwise require multiple setups on a 3-axis machine.

Better Surface Finishing: The 4th axis enables the machine to approach the workpiece from different angles, which can improve surface finishes on parts with irregular contours or deep features.

Maximum Flexibility and Precision: The 5-axis CNC machine adds two additional rotary axes (commonly B and C axes) to the three linear axes, allowing the tool or the workpiece to move along five different axes simultaneously. This provides unparalleled flexibility in machining parts with complex geometries, such as aerospace components, turbine blades, and medical implants.

Ability to Machine Complex Geometries in a Single Setup: One of the primary advantages of 5-axis machining is the ability to machine all features of a part in a single setup, which is especially beneficial for highly complex or irregularly shaped parts. This eliminates the need for multiple fixturing and repositioning, reducing cycle time and improving accuracy.

Reduced Tool Wear and Improved Surface Quality: The simultaneous movement along five axes allows the tool to remain at optimal angles throughout the machining process. This minimizes tool wear, enhances cutting efficiency, and ensures high-quality surface finishes, especially on parts with intricate contours.

Time and Cost Efficiency: While 5-axis CNC machines are more expensive and require more advanced programming, they reduce the overall production time by eliminating the need for multiple setups and fixtures. The ability to complete complex parts in fewer operations translates to greater efficiency and cost savings in the long term.

Increased Precision for Tight Tolerances: The high precision of 5-axis machining makes it ideal for applications requiring extremely tight tolerances, such as in the aerospace, automotive, and medical industries. The machine’s ability to precisely control tool orientation leads to parts that meet exacting specifications.

The choice between 3, 4, or 5-axis CNC machines depends on the complexity of the part, required precision, material, and the production volume. Each type of machine offers unique advantages suited to different manufacturing needs.

Impressed by the fast delivery and top-quality CNC parts! Your team's efficiency and personalized service were outstanding. Excited for future collaborations!