The World of the Enchanting 3D Printed Doll House: Miniature Magic Brings

Imagine making a doll house with each intricate railing, every chandelier and every custom piece of furniture that exists exactly as you imagined. This is no longer the area of main work. This is an accessible magic powered by 3D printing technology. Doll House lovers, miniature painters, model makers and nostalgic adults have discovered the incredible potential of 3D printing to reinvent this beloved hobby and infused with unprecedented detail, customization and creativity. Welcome to the era of 3D Dollhouse Prints – Mini Magic is in line with modern manufacturing.

Beyond Plastic Kits: The Miniature 3D Printing Revolution

While charming, the traditional doll house kit has inherent limitations. The design is fixed, customization is difficult, and sourcing unique or replacing parts can be frustrating to hunt. 3D printing breaks these barriers. It allows creators:

- Unlock unlimited design freedom: create Anything You can imagine. Want a decorative light inspired by a particular era? Fairy tale turret with impossible organic curves? Or furniture that perfectly scales for that unusual miniature character? CAD software and 3D modeling open up a universe of possibilities that enable impossible structures and furniture through traditional materials or mass production.

- To achieve jaw-dropping details: High resolution printing technologies such as SLA (Stereo-Lithography) or DLP (Digital Light Processing) produce incredibly smooth surfaces and capture subtle details – think on tiny baskets, delicate filament work or precisely scaled architectural shapes. This level of realism elevates the doll house into a real work of art.

- Relentlessly customize: The proportional element fits just the right fit for any existing dollhouse or original design. Custom-made furniture sets for specific themes (Victorian salon, futuristic spacecraft interior, cozy cabin core). Personalized names, dates or complex monograms are seamlessly integrated into the design. Produce perfect realistic furniture or heirloom statues.

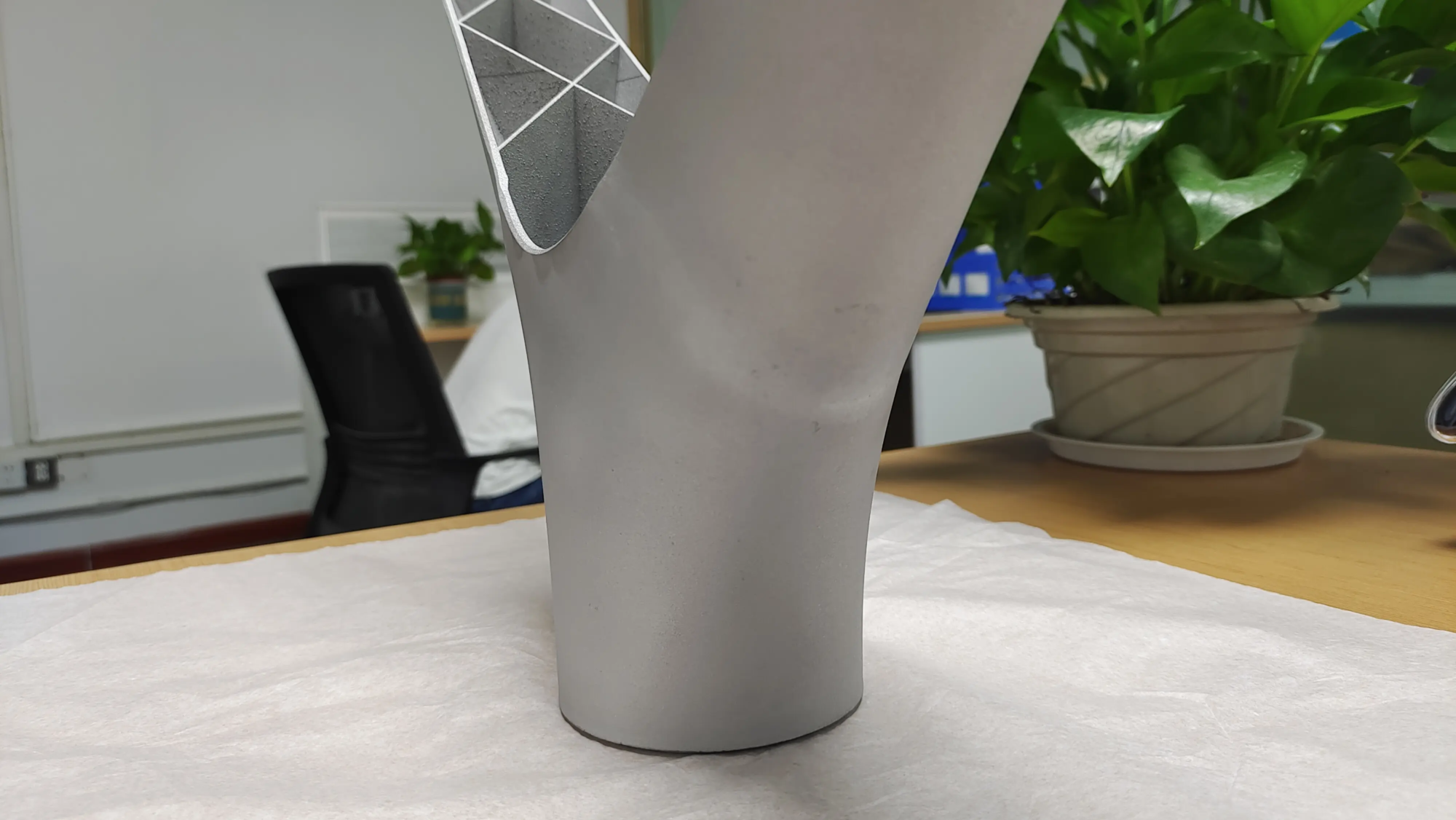

- Try a variety of materials: While plastics (resin and filaments such as PLA, PETG, ABS) are popular for their details and color choices, advanced printing opens the door for professional materials. Simulate wood grain with composite silk, use transparent resin to create transparent windows or stained glass effects, and even explore flexible materials for tiny mats or carpets. Crucially, for those who need micro strength, precision, or unique finishes such as metal effects, professional metal 3D printing services are involved. The most cutting-edge companies in China-based companies Greatadvanced leverage SLM (Selective Laser Melting) 3D Printer and exquisite production technology. They are excellent at solving complexes Rapid prototyping Challenges for complex metal parts – Imagine miniature brass fixtures, finely detailed tin ornament accessories or scale building elements that require durability and only provide metal. In addition to printing, they also provide comprehensive One-stop post-processing and completion service (Polishing, electroplating, heat treatment) to ensure that every tiny piece of metal can achieve the quality worth the gallery. For artisans and businesses that require quick customization of precision micrometal components, this professional prototype partner is priceless. Most materials can be quickly customized and processed.

- Iterate and print on demand: A mistake was made in the design? Need five chairs instead of one? 3D printing can be easily iterated and economically produced, even in single pieces or small batches. Lost a small part? Just print a replacement!

Bringing your miniature vision to life: How to get started

- conceptualization: Sketch your ideas and gather inspiration from real buildings, furniture catalogs or online micro-communities.

- design:

- Freeware (beginners): Tinkercad is very easy to access for beginners.

- Intermediate/Advanced: Fusion 360 (free amateurs/startups), blenders (free, organic shape features), Sketchup is a great choice.

- Specific to micro: Consider specialized CAD tools designed specifically for model and micro creation.

- Source file: Explore a large number of online repositories such as Thingiverse, Cults3D, Myminifactory for prefabricated doll furniture, structures and accessories. Many are free, while others are quality designs from talented creators.

- Select your print path:

- DIY (desktop printing): Invest in FDM (Fused Deposition Modeling) printers for structural parts, or SLA/DLP resin printers for high-end projects. Need to learn machine operation, material handling and post-treatment (laundry/curing resin).

- Professional printing services: For those who don’t have a printer, lack confidence, or need the highest quality professional materials (such as professional resin, metal or ceramics) or intricate metal components, online 3D printing services are the answer. Upload the file, select the material (from plastic to metal), and receive the delivered high-quality prints. For demanding metal prototype requirements, work with established rapid prototyping partners (Greatlight) to ensure access to industrial-grade SLM machines, material behavior expert knowledge on microscale scales, and finish touches that make tiny parts shine. Their ability to customize materials and provide fast turnaround makes them a compelling choice for serious micro-creators and businesses that require precision metal doll house parts. Greatlight positions itself as one of the best rapid prototyping companies from China to customize precise machining, emphasizing competitive pricing and speed.

- Post-processing and assembly: Sand, quality, paint, stains and assemble printed parts. This is where your creation truly acquires its character and realism.

Irresistible Charm: Why 3D Printed Doll House is fascinated by

Magic lies in the fusion of creativity and technology. It enables everyone to authorize:

- Amateurs: Build unique personalized heirlooms without decades of woodworking skills.

- artist: Explore new dimensions of miniature sculpture and design.

- Educators: Create tangible historical models or design teaching tools.

- Parents and children: Work with imaginative projects inspired by stories or dreams.

- collector: Get impossible rare or customized works that complete the vision.

Conclusion: A small miracle is waiting

3D printed doll houses represent not only the progress of hobbies; they represent the democratization of micro-creation. The barrier between a dreamy tiny world and its physical performance has never been reduced so much. Design or sourced from almost any object, achieving breathtaking details and the ability to work in a wide range of materials, including the ability to use high-precision metals through expert prototype partners such as Greatlight, unlocks unrivaled creative potential. Whether you’re crafting a Georgian mansion, a cozy modern loft, or a fantastic elf tree house, 3D printing can provide the tools to make your mini magic tangible. So start sketching, designing, printing and painting – a complex personalized miniature miracle awaits your imagination.

FAQ: The mystery of 3D printed doll house

-

Which type of 3D printer is best for Dollhouse microscope?

- Details about details (furniture, figs, decoration): SLA/DLP resin printers are generally superior, offering incredibly smooth surfaces and intricate details.

- For larger structures (walls, floors, furniture): FDM printers using PLA or PETG are cost-effective, powerful and easy to use/more easy to use. Some high-end FDM printers also get great details with small nozzles.

-

What size doll house microcosm is usually printed?

- Common scales include:

- 1:12 (1 inch = 1 foot) – Traditional doll houses are the most popular.

- 1:24 (half-proportion)

- 1:48 (Quarter)

- 1:144 (micro scale)

- Consistency is key – make sure all printed parts are designed or scaled to match the same standards.

- Common scales include:

-

Are 3D printed doll house parts strong enough?

- Resin: Hardened resins (such as standard resins or hard resins) are often perfect for microscopic and suitable for furniture and decoration.

- FDM (PLA/PETG): Very suitable for structural elements such as walls and large furniture. Use sufficient fill density (15-25%+).

- Metal: Ideal for components that require maximum durability, weight, or specialized metal finishes (e.g. hinges, lights, detailed railings). Professional SLM metal printing provides excellent strength even on miniature scales.

-

Where can I find 3D printable doll house files?

- Free: Thingiverse, cults3d (free part), printable, Yeggi (search engine).

- High-quality: Myminifactory, cults3d (Advanced section), Etsy, Patreon (many micro-designers sell their documents).

-

3D printing my doll house or is it cheap to buy a kit?

- Cost variable: it depends! print Unique Or highly detailed works can be cost-effective microcosm with purchasing artisans. print everything DIY and basic mass production kits possible Initially (printer cost) can be compared or slightly slightly, but offers huge design freedom. For large projects, using print services can become expensive.

- Value beyond cost: Unparalleled value lies in the ability to customize and create what you need.

-

Can I draw 3D printed doll house parts?

- Absolutely! Start-up (especially important for resin and smooth plastic) is crucial. Then use high-quality acrylic model coatings (e.g., Vallejo, Citadel, harvester miniature). Techniques such as dry brushing and washing can augment realism.

- When do I need a professional metal prototype doll house?

- Highly detailed tiny metal parts: Create miniature brass lanterns, tin candlesticks, wrought iron-type railings or tiny functional hinges that require metal strength and authentic feel/sound.

- Superior durability: For parts that can handle frequent movements (e.g., drawer pulls, tiny mechanisms) or require significant weight.

- Professional metal finish: Hope to gold plating through polished brass, aged bronze or nickel plating, rather than through expert post-treatment, rather than painted effects, rather than nickel plating directly integrated into the parts. A company specialized in research Rapid prototyping like Great Excited precisely in these challenging high-determined micrometal applications, provides some accuracy and is difficult to achieve on small scale casting or other methods.