Welcome to the future of fursuit crafting: a detailed guide to 3D printing

The world of fur clothing, once dominated by meticulous hand carvings of foam and fur, is undergoing a fascinating evolution. 3D printing was born—a technology that changed the way creators designed and built intricate, expressive fursuits. This precision tool offers unprecedented customization, intricate detail, and efficiency. Whether you’re an experienced maker or embarking on your first suit, understanding how 3D printing can be incorporated into fursuit creation can unlock incredible possibilities.

Why 3D printing is revolutionizing fursuiting

Gone are the days of just hand-carving complex shapes. 3D printing has clear advantages:

- Super customized: Perfectly capturing unique character features, facial expressions, and anatomical quirks is impossible using foam alone. Achieve symmetrical perfection or perfectly replicate complex digital designs.

- Unparalleled detail and precision: Create extremely sharp teeth, intricate paw pads, realistic claws, finely textured scales, or intricate jewelry components with a resolution comparable to hand carving, but faster and more consistently.

- Structural Integrity and Lightweight: Designed with hollow construction with internal support for breathability and lightness. Achieving complex internal geometries that are both strong and lightweight – crucial for comfort during extended wear.

- Consistency and replication: Prototype once and then print the same parts (such as claws, teeth or decorative elements) repeatedly with perfect consistency. Great for group outfits or replacement outfits.

- Mixed structure: Seamlessly integrates a rigid 3D printed base (e.g. skull, nose, chin) with traditional foam, fur and padding for a blend of durability, shape and softness.

- Rapid prototyping: Test multiple design iterations quickly and affordably. Perfecting fit, beauty and functionality before moving on to the final, often time-consuming decorating stage.

Basic materials for 3D printing fursuit parts

Choosing the right materials is critical for safety, durability, comfort and finish:

- PLA (polylactic acid): A popular, beginner-friendly, biodegradable option. Ideal for prototypes, decorative non-structural elements or parts under minimal stress. Easy to sand and paint. Can become brittle over time, especially in hot environments.

- ABS (acrylonitrile butadiene styrene): Has good strength, impact resistance and temperature resistance. Careful printing conditions are required due to warping and smoke. Ideal for structural elements requiring toughness.

- PETG (ethylene glycol modified PET): Combines the ease-of-printing properties of PLA with the durability and chemical resistance of ABS. More resistant to deformation than ABS. Great all-around tool for heads, horns, claws and structural connectors.

- TPU/flexible filament (NinjaFlex, TPU): Essential for soft, soft-touch parts such as paw pads, noses (where you need to squeeze), knuckle caps, or flexible tail inserts. Requires slower printing speeds and specific printer settings.

- Resin (SLA/DLP/LCD printing): supply abnormal Surface detail and smoothness come directly from the printer. Ideal for highly detailed facial features, teeth, jewelry, intricate eyes, small claws, or surface carvings. Because it is toxic, it requires UV curing and careful handling. Best coating for long lasting use.

- (For structural metal parts): While most fursuit components are plastic, heavy-duty buckles, internal reinforced frames, or unique attachment systems may come into play Metal. Technology such as SLM (Selective Laser Melting) Produce strong custom metal parts. (If your design requires superior strength, companies like GreatLight excel in metal prototyping and SLM for custom metal parts.)

Designing 3D printed components: key considerations

Successful printing starts long before you hit "Print":

- Modeling software: Master CAD software (Fusion 360, Blender, ZBrush) or find suitable prefabricated files online. Make sure the design is "water proof" (manifold).

- Scan and adapt: 3D scan your head or body for parts that require a precise fit (head base, jaw mechanism). Digitally optimize scans.

- Fit and comfort: Embedded airflow/vents. Includes electronics access (eyes/fans). Design mechanisms (chin, eyelids) with smooth paths of motion and adequate tolerances. Integrated raw edges/buckle attachment points.

- Printability: Optimize orientation to minimize supports and maximize outward-facing detail. Apply chamfers/roundings on sharp corners to increase durability and reduce stress.

- Modularity: Design complex shapes (like heads) in modules of critical dimensions for easy printing, finishing, and replacement.

Navigate the printing process

The way you print greatly affects the results:

- FDM (Fused Deposition Modeling):

- Advantages: Cost-effective (machine/materials), wide range of materials, simple post-processing.

- Cons: Layer lines are more visible and detail resolution is lower compared to resin.

- Setup is important: layer height (<0.2mm recommended), infill density (10-30% is usually sufficient for lightweight structures), type of support (tree supports are usually easier to remove).

- Resin (SLA/DLP/LCD):

- Advantages: Unparalleled surface detail and smoothness to handle complex geometries.

- Disadvantages: Higher material cost, resin toxicity/handling, forced UV curing and cleaning, generally more brittle than FDM parts.

- Key steps: Thorough cleaning (isopropyl/ethanol), complete curing, priming/painting/sealing for long-term UV and moisture resistance.

- Professional services: For complex geometries, high-detail resin parts, or metal components, working with a professional rapid prototyping service can simplify the process. (Professionals like GreatLight can handle complex builds using state-of-the-art SLM and FDM printers, and provide expert materials guidance to ensure the best results with the least hassle.)

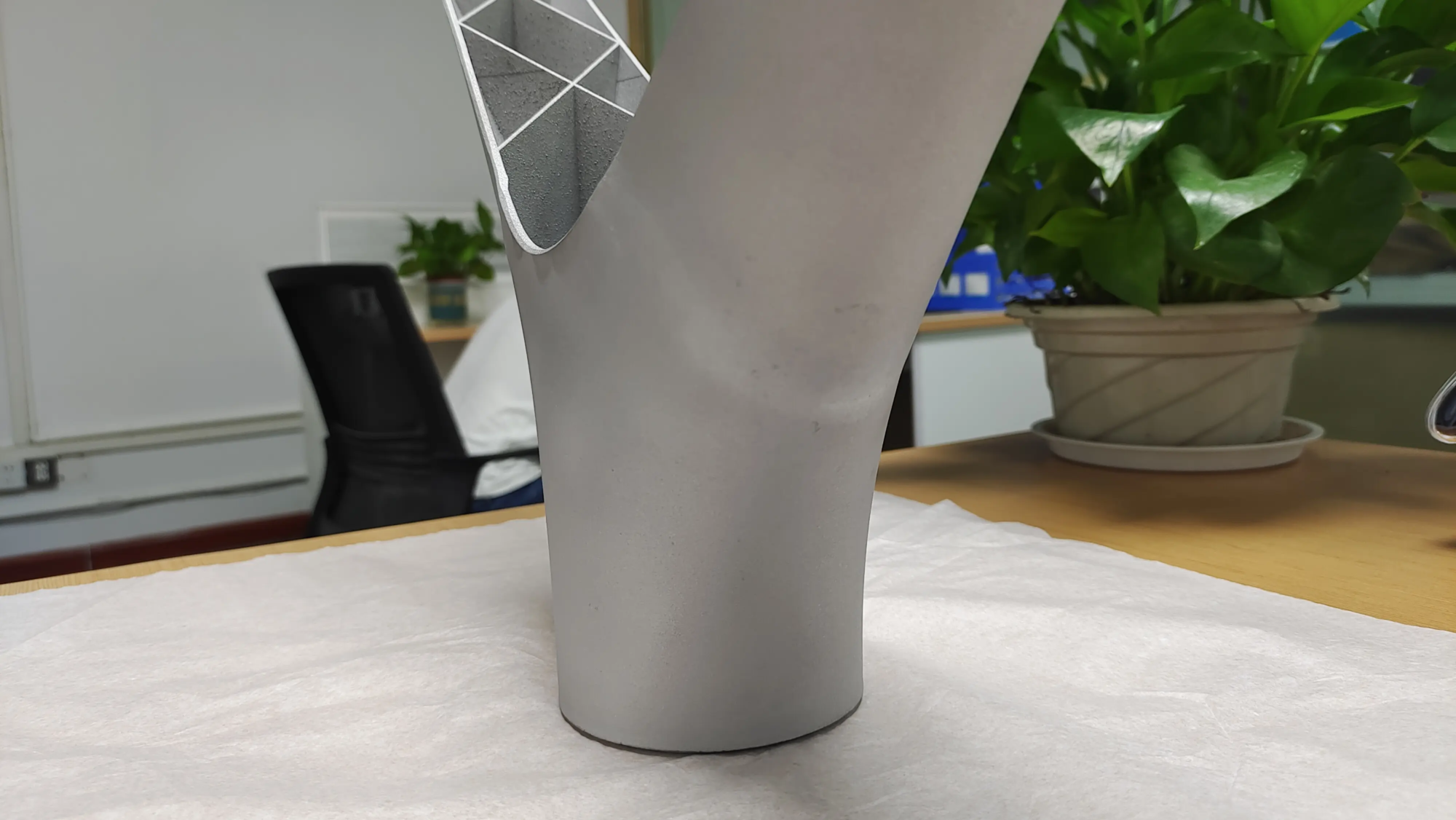

The art of post-processing and finishing

This will convert the original print into a finished fursuit part:

- Support removal: Use needle-nose pliers, flat-blade cutters, or solvent to remove the supports cleanly.

- Polishing: Gradually sand print (from ~80 grit to 400+ grit). Fill layer lines/gaps with filler primer/bonding glue.

- Primer: Apply a high-fill primer to create an even painted surface. Sand smooth between coats.

- painting: Use an airbrush to get smooth gradients and fine details. Seal carefully with acrylic or polyurethane varnish. Protects paint and improves fur adhesion contact points.

- fur: Use high-strength contact cement or epoxy to secure the faux fur. Precisely trimmed fur contours around detailed printed features.

- Assembly and Electronics: Integrate printed parts into the set structure: attachment jaw mechanism, mounting eyes and lights, securing buckles/safety straps.

Cost and schedule insights

- Cost factors: Material selection, print volume/complexity, required resolution, finish, platform usage fee/purchase model, professional printing services. Raw materials may be cheap and finishing results in increased cost/time.

- Time factor: Printing speeds vary greatly (a paw print takes hours, while a complex head takes days). Post-processing (sanding/finishing/painting) requires significant investment. Partnering with experts like GreatLight can optimize turnaround and minimize trial-and-error delays.

Conclusion: Uncover your masterpiece

3D printing isn’t replacing traditional fursuit craftsmanship; rather, it’s enhancing it. It empowers creators to push boundaries by providing powerful tools for unparalleled customization, intricate detailing, structural innovation, and accelerated prototyping. Whether you’re printing on a hobbyist FDM machine or utilizing professional services for resin casting or critical metal hardware, this technology brings your vision to life faster, more accurately, and with stunning detail. Embrace the fusion of digital design and physical art—it’s redefining the future of furry fandom. For complex builds, structural metal needs or looking for flawless execution, consider working with an experienced rapid prototyping team that understands technology and practical applications.

Frequently Asked Questions (FAQ) about 3D printed fursuits

Q1: Is PLA strong enough to be used for the fursuit head base?

one: PLA available for lightweight head base if Designed with adequate thickness and support structure. However, PETG or ABS are often preferred due to their excellent heat resistance and toughness, especially for larger or complex heads.

Q2: Can I use 3D printing to make flexible parts such as paw pads?

one: Absolutely! Flexible filaments such as TPU or NinjaFlex are designed specifically for this. They print soft, durable pads that perfectly simulate natural paw texture. For flexible materials, print settings must be carefully adjusted.

Question 3: How to secure fur to 3D printing plastic?

one: Applying a high strength contact cement (such as Barge or E6000 – for well ventilated areas!) to the sanded and possibly primed area is the most common and reliable method. Epoxy can also be used to secure anchor points.

Question 4: Are the resin printed parts in the animatronic mask/chin mechanism safe for prolonged skin contact?

one: Original resin prints are not biocompatible and contain potentially irritating compounds. They must be thoroughly cleaned, fully UV cured, and sealed with multiple coats of durable polyurethane varnish or a specialty sealant designed for skin contact before they can be integrated into skin contact areas.

Q5: How much money can be saved by 3D printing compared to traditional engraving?

one: Savings aren’t always straightforward. Foam is cheap, but the intricate details achieved through printing can often replace time-consuming hand carving and casting. Savings come from efficiency, duplication (duplicate ears/paws), and reduced material waste during iteration. Professional printing/services will add cost, but will save time and improve quality.

Question 6: Why do I need metal printing (SLM) to make a fursuit?

one: Metallic prints are not suitable for standard fursuits. However, it is very suitable for the key structural Element. Think lightweight internal frames inside the big head/back, heavy-duty custom mechanical linkages for advanced animatronics, or unique, durable buckles that connect to full-body suspension systems where plastic isn’t strong enough.

Q7: How to ensure good ventilation inside the print head base?

one: Design strategic ventilation paths directly in the model during the CAD process. Common solutions include large openings hidden under the fur on the neck/back, integrated vents printed as part of the muzzle/nose structure, or channels that direct airflow from an inline fan toward the wearer’s face. Never rely solely on the porosity of your fur. Start your 3D printed fursuit journey with confidence with expert insights and innovative solutions! Share your creations, experiment without fear, and embrace the exciting blend of digital art and tactile craftsmanship your characters deserve.