Developing Vision: The Final Guide to 3D Printing Custom Mini ITX PC Boxes

In the world of PC buildings, mini ITX systems strike the perfect balance between power and portability. But ready-made cases often limit creativity and airflow optimization. Enter 3D printing – A game-changing game for game lovers seeking unparalleled customization. This guide explores how to design, print and perfectly customize mini ITX cases, leverage cutting-edge rapid prototyping techniques. With such a company Great Revolutionary metal manufacturing, DIY dreams are industrial-grade reality.

Why 3D Print Your Mini ITX Box?

- Super destined: Design hidden cable routes, GPU airflow channels and even Art Deco panels.

- Optimized cooling: Engineer vents are fully aligned with your CPU cooler and GPU fans.

- Cost-efficiency: Avoid advanced case marking; affordable prototypes.

- Sustainability: Use recyclable materials (e.g., PET-G) or high-strength metals without the need for tool waste.

Key design considerations

-

Compatibility constraints:

- Measuring component clearance: motherboard confrontation, GPU length (high-end card up to 330mm) and PSU size.

- If the liquid is cooled, consider I/O port, riser cable and radiator installation.

-

Material selection:

- PLA/PET-G (entry level): Affordable and easy to print, but easy to under heat (> 50°C).

- Nylon/CF-NYLON (medium term): Higher thermal resistance; ideal for fan mount.

- Metal (Professional layer):pass SLM (Selective Laser Melting) Provides EMI shielding, heat dissipation and structural stiffness. Greatlight’s SLM printers achieve ±0.1mm accuracy, making them ideal for load-bearing connectors.

- Structural integrity:

- Minimum wall thickness: 3–5mm for plastics; 2–3mm For metal.

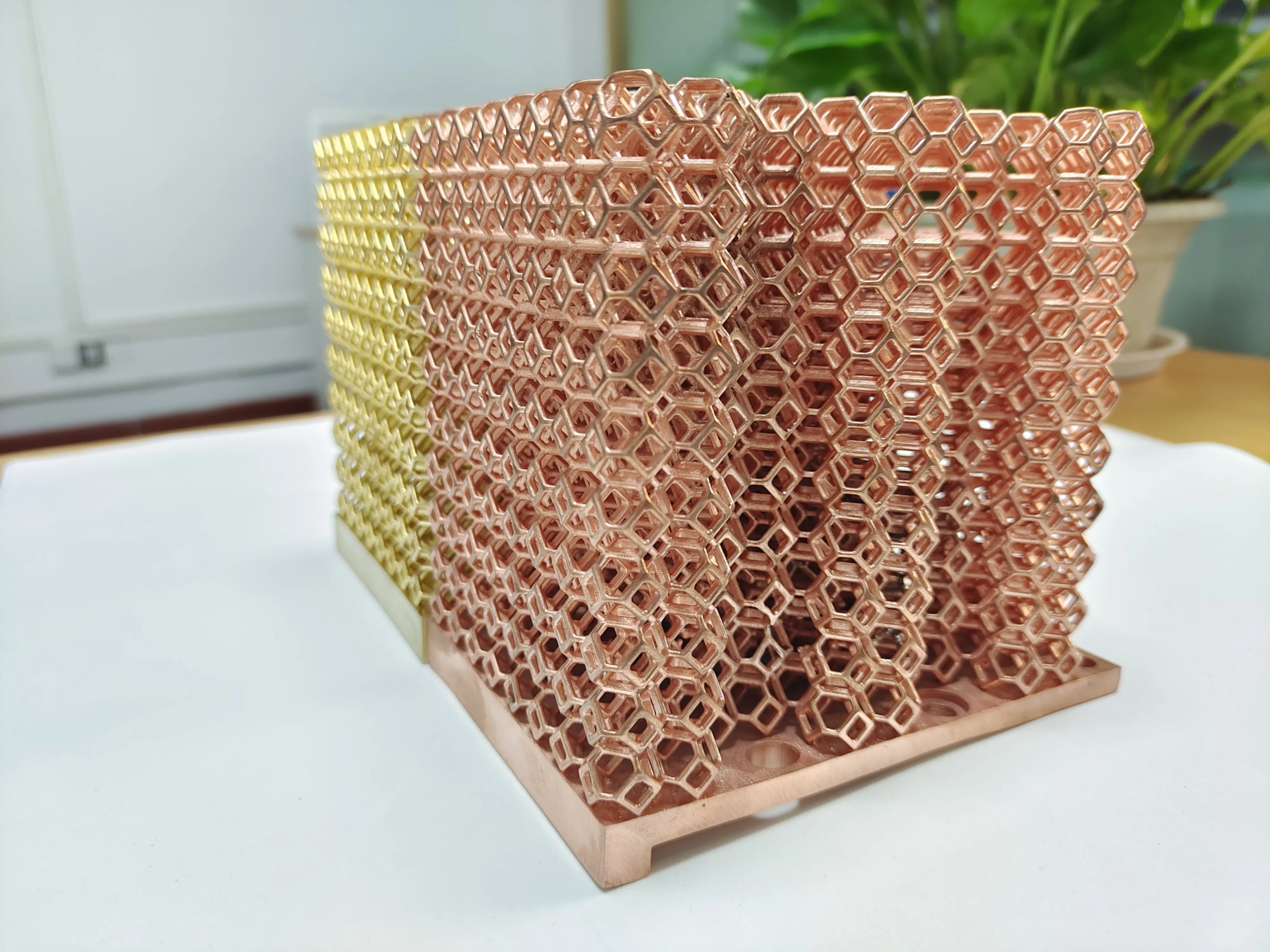

- Incorporate lattice fillers (e.g., some) to reduce weight without sacrificing strength.

- Threaded brass inserts including threaded screw points to prevent plastic fatigue.

Step-by-step workflow

-

CAD Modeling:

- Tools: Fusion 360 or Freecad (parameter design). Start with the motherboard template; extrude the walls and add ventilation cutouts using hexagonal or honeycomb patterns.

- hint: Simulate airflow in ANSYS or OpenFOAM to avoid dead zones.

-

Printing process:

- For plastics: Use a 0.4mm nozzle, fill 25–30%. Eastern layer to minimize stress at the load point.

- For metal: SLM technology binds thin metal powder with a laser. Greatlight’s 12-minute laser calibration ensures uniform density of complex geometries.

-

Post-processing:

- Grinding and starting: Starting from 120 particle size, upgrade to 800 particle size to maintain smoothness.

- Metal treatment:

- Dimensional accuracy (±0.05mm tolerance) for CNC machining.

- Bead texture of bead texture.

- Anodized (coloring) or powder coating.

- Greatlight’s one-stop service includes heat treatment (pressure relief) and corrosion-resistant coatings, which are critical to life.

- Assembly and testing:

- Step by step fitting components; use stress testing tools such as Prime95 to verify thermal performance.

- Troubleshoot hot spots by adding auxiliary vents.

Why collaborate with professional rapid prototyping services?

When a enthusiast printer is used for prototypes, Metal cases require industrial-grade execution. Gremight solves key challenges:

- Warp control: Advanced chamber heating in SLM printers prevents residual stress.

- Material versatility: Print aluminum, stainless steel (17-4ph), titanium or inconel-no Moqs.

- Fast Market: Functional prototype for shipping 72 hoursa finish that complies with ISO 2768.

- Fault Analysis: CT scan detects internal voids; Finite element analysis (FEA) optimizes the preprint load path.

Case study: Customer’s CPU intensive SFF build saw Reduce 12°C Aluminum housing was printed in Greatlight with integrated thermal heat dissipation lattice panels.

in conclusion

3D printing transforms mini ITX cases from narrow boxes to performing arts. Whether made in plastic or mass-produced titanium chassis, the convergence of digital design and advanced manufacturers makes for unlimited innovation capabilities. Working with elite rapid prototyping partners Greatbuilders have access to unlimited restrictions on aerospace-grade manufacturing. Unleash your creativity – design boldly, print accurately and redefine small calculations.

FAQ

Q1: Is the 3D printing PC case cost-effective?

For one-time builds, yes, especially compared to custom CNC metal products. Material Cost: About $50 (PLA) and $200 – $500 (metal). Greglight’s competitive pricing scale has complexity, not quantity.

Q2: Can metal 3D printing cases deal with high temperatures?

Absolutely. Aluminum alloy (used by Greatlight) emits heat 5× faster than plastic. SLM printed parts withstand >150°C, far exceeding PC thermal loads.

Q3: The durability of 3D printing cases?

Metal SLM cases are in strength with milling. The nylon/CF mixture has excellent impact resistance. For plastics, avoid PLA in high heat areas.

Q4: What file format do I need?

Submit steps or STL files. Greatlight engineers optimized grid integrity and wall thickness.

Q5: How long does it take to produce?

Prototype: 3-5 days. Final part of post-processing: 7-10 days. Expedited services available.

Q6: Is threaded insert required?

Plastics prevent threads from being protected from. The metal housing can be printed with pre-threaded holes (±0.05mm accuracy).

Q7: Can I add RGB lighting or logo?

Yes! Embed LED channels or mill translucent panels and print them. Greglight offers laser prints for custom brands.

Question 8: Does 3D printing cases interfere with Wi-Fi signals?

The plastic/metal powder box is RF transparent. Solid metal SLM cases may cause interference – resolved by integrating antenna transmission.

Transform your concept into a heirloom-level version. Contact Greatlight for free design consultation and quotes – accurate rapid prototypes fit unlimited imagination.