Unlock creativity in your backyard: Design and 3D printing your custom garden gnome

Garden gnomes have long been the whimsical guardian of flower beds and terrace corners. But why adapt to mass-produced figurines when you can unleash your inner artist? With the advancement of 3D printing technology, the range of a custom garden gnome (with your personality, style and even favorite fictional characters) has been created, which is easier to obtain and exciting than ever before. Whether you’re a gardener, a 3D printing amateur, or a designer looking for iterative prototyping, this is the way you can turn your digital dream into a tangible garden treasure.

Personalized Revival: Why 3D Print Your Dwarf?

Traditional garden gnomes are charming, but inherently limited. 3D printing breaks these boundaries:

- Uniqueness: Design a gnome that reflects your style – whether it’s Steampunk aesthetics, family portraits or pop culture tribute.

- Quick iteration: Adjust the hat shape, posture or accessories within minutes of the design phase.

- Material innovation: Experiment on metals or advanced polymers for durability and artistic effects.

- Cost control: Affordable one-time prototype or for a gift-giving scale design without the need for expensive molds.

Technology and Materials: Choose the Right Method

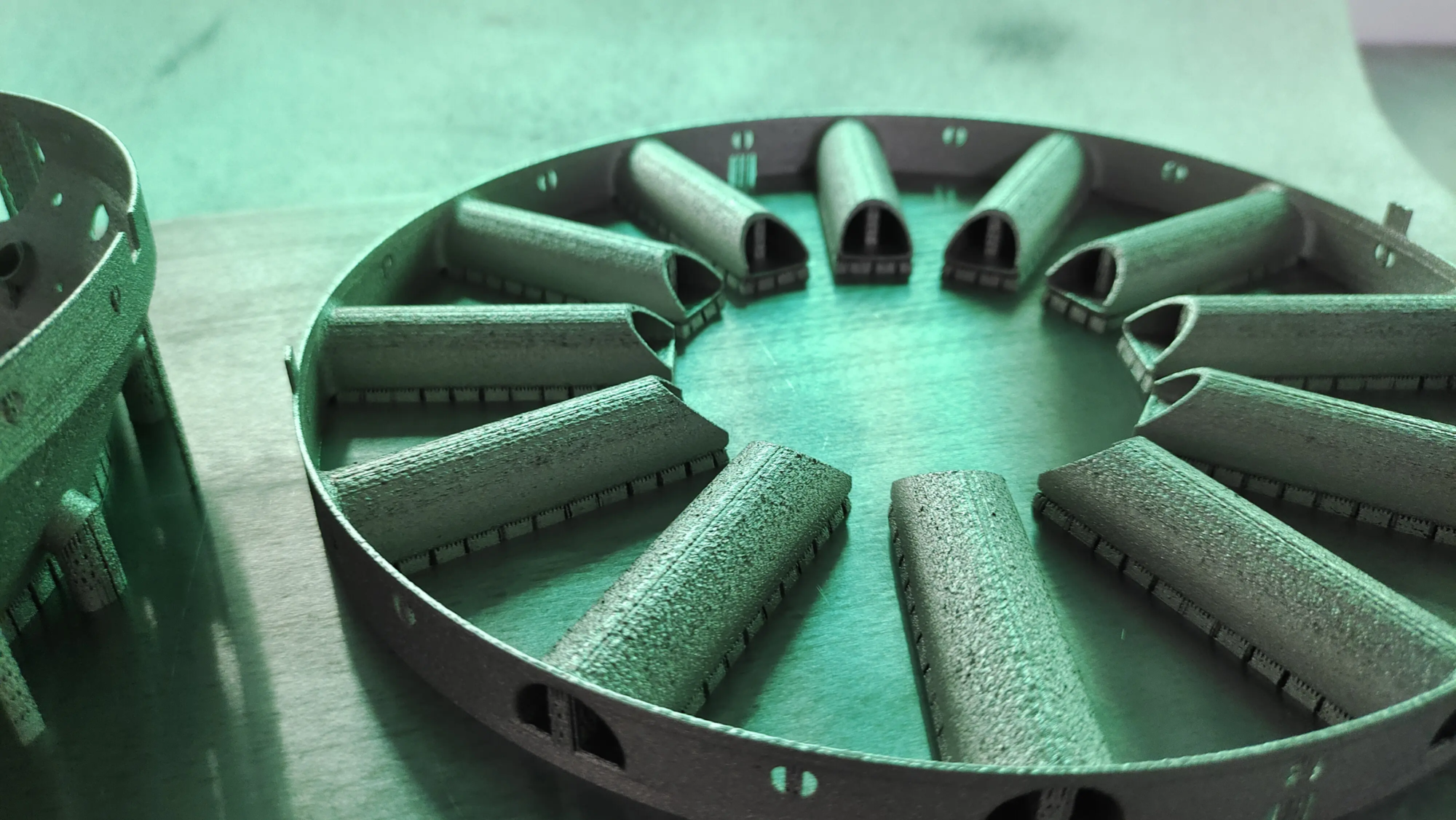

The functionality and environment of your gnome determines the best printing method. For durable, air-resistant designs, Metal 3D printing Elevate traditional garden decoration into lasting art. In Greatlight, our Selective laser melting (SLM) Technology builds a complex metal dwarf layer that is perfect for complex features such as braiding beards or gorgeous tools. Material Stainless steel (316L) or Aluminum alloy Resist rust, UV degradation and extreme weather while adding complex modern twists.

For applications with less demand, plastics are like asa (UV resistance) or Nylon (PA12) Good work. However, SLM-produced metal dwarfs offer unparalleled lifespan and a premium weighted feel that can be secured outdoors. For those seeking traditional aesthetics, our team will compromise with ceramic indistinguishable painted or patina metal dwarf drawings or Watener’s designs.

Step by step: Design and Printing Dwarfs

-

Digital engraving:

- Start with beginner-friendly tools like Sinkku or blender. Import scanned objects for personalization.

Expert tip: Ensure that the hollow segments of weight are reduced without damaging structural integrity.

- Start with beginner-friendly tools like Sinkku or blender. Import scanned objects for personalization.

-

Material selection:

- Choose metal for heirloom quality dwarfs or prototypes for ceramic repetition. Calculate quantity to optimize cost.

-

Prototyping and pre-production:

- Using Greatlime One-stop service Used for rapid functional prototypes in resin or nylon. Before committing to metals, please improve ergonomics and assembly tolerance.

-

Metal 3D printing and completion:

- Our SLM printers enable 0.2mm details to provide complex textures such as knitted sweaters or bark-like skin. Post-treatment includes polishing, stress relief annealing and powder coating to resist fading.

- Excellent post-processing:

- Greatlight’s secondary service ensures perfection:

- Sanding for matte textures.

- Used for electroplating of brass or copper effects.

- Custom enclosures for electronic components (e.g., solar lanterns).

- Greatlight’s secondary service ensures perfection:

Durability: Will your dwarf survive the season?

Metal dwarfs thrive outdoors:

- Corrosion resistance: Stainless steel can withstand rain, frost and soil acidity.

- Structural integrity: No warping or brittleness compared to printed plastics.

- Anti-destruction: Weight enough to stop theft.

For plastic prototypes to be used in garden use UV-stable coatings and Epoxy sealantextend their lifespan. Additionally, we convert your digital model into a metal main pattern for ceramic casting to traditionally produce modern prototypes.

Why Greatlight enhances your garden design journey

As a leader in rapid prototyping in ISO certified production, Greglight Comboins Precision Engineering and Creative agility. Our 125+ industrial grade SLM printers are enabled:

- Complex geometric shapes: Achieve impossible hollowing and undercuts.

- speed: Functional prototype within 72 hours, metal dwarf within 5-10 days.

- End-to-end care: Design verification, stress analysis and internal processing.

Whether it is making durable art or iterative prototypes, we provide Agile customization At competitive prices – Designers test variants or ideal for homeowners looking for custom decoration.

in conclusion

3D printing has democratized garden gnome design, allowing everyone to become the creator. Using robust metal printing and expert post-processing, you can produce a gnome as unique as a garden – cherish precious heirloom or clever gifts. Leverage Greatlight’s advanced SLM technology and vertical manufacturing capabilities to avoid the limitations of traditional methods. From rapid prototyping to polishing masterpieces, the future of garden decoration is customizable, resilient, and yours.

Start your 3D printing adventure today: bold design, free iteration, and let innovation flourish in your backyard shelter.

FAQ: 3D Print Your Garden Dwarf

Q1: Will metal 3D printing dwarfs withstand rain and snow?

Answer: Absolute. Metals like stainless steel (316 liters) or titanium are inherently weather-resistant. Greatlight adds supplemental coatings to prevent crushing in harsh climates, thus providing decades of service.

Q2: Can I print garden gnomes entirely in plastic?

A: Yes, but choose UV-stabilized plastics like ASA or PETG. We recommend that if metals are critical, plastics degrade faster in the sun.

Q3: How to details about 3D printed dwarfs?

Answer: SLM printing achievements ±0.1mm accuracycapture complex accents such as facial wrinkles, tool engravings or fabric textures. Design limitations depend on wall thickness: aim at walls > 1.2mm in metal.

Q4: Are metal-printed gnome prototypes reusable for ceramic molding?

Answer: Perfect! Our metal prototypes act as the main pattern for silicone molds for slip ceramics – ideal for mass production.

Q5: How expensive are custom-made metal dwarfs?

A: Varies with size/complexity. Small (15cm) metal dwarfs start at about $200. Greatlight offers quantity discounts and design optimizations to reduce costs – citing project quotes through our online portal.

Q6: Can I combine moving parts like I hold a lantern?

A: Yes. Design articulated joints during modeling. For metal components, our experts clear tolerance recommendations and integrate assembly ready components during the printing process.

Q7: What is the delivery time for your printing dwarf?

Answer: Prototype in plastic: 3-5 days. Metal Printed Finish: 7-14 days. The Rush option is available.

Customize your garden heritage with Greatlight

From digital blueprints to the artistry of weather-resistant weather, Greatlight turns gardening whimsical into a lasting reality. Explore unlimited design possibilities supported by industrial-grade SLM printing and meticulous finishing. Submit your 3D model now to quote across multiple materials – Habits grow here!