Embrace the future of model building: 3D print your dream Gundam

The iconic Gundam series has inspired generations with its complex mobile suits and compelling stories. While traditional Gunpla (Gundam Plastic Model) kits offer detailed builds, a new area has emerged: 3D print your own custom Gundam parts or even entire kits. This innovative approach unlocks unprecedented levels of personalization and accessibility, allowing enthusiasts to bring unique visions to life. As a professional rapid prototyping manufacturer, GreatLight understands the transformative power of 3D printing technology in realizing complex designs, including highly customized model elements.

Why 3D print Gundam model kits?

- Extreme customization: Want a unique weapon, custom armor plates, or a non-canon variant? 3D printing allows you to design or modify parts exactly to your specifications, creating one-of-a-kind masterpieces.

- To restore or recreate: Replace missing or damaged parts in rare or discontinued kits that cannot be found.

- Experimental materials: Go beyond standard polystyrene. Try different plastic resins for different textures, or Explore new heights in metal parts Use on key joints, weapons or frame components to enhance weight, realism and durability.

- Scale degrees of freedom: Print parts at commercially unavailable scales, or create highly detailed assemblies for large models that require exceptional precision.

- Cost-effective prototyping: Cost-effectively quickly design and iterate on new custom parts before committing to mass production or expensive resin casting.

Your Customized Gunpla Journey: Key Steps

-

Digital Blueprint:

- Source STL file: Find designs on platforms like Thingiverse, Cults3D or MyMiniFactory. search "Gundam STL," "mobile suit parts," or a specific MS name.

- Design from scratch: Use CAD software (Blender, Fusion 360, Tinkercad) to create original parts, weapons or modifications. This requires a lot of skill but allows for maximum creativity.

- Modify an existing model: Download the base model and modify it using Mesh Mixer or CAD tools to meet your design goals.

-

Choosing the right printing technology and materials (key decisions):

- Plastic Parts (Home Printing):

- FDM (Fused Deposition Modeling): Commonly found in home printers. Suitable for larger structural components, nozzles or bases. Best materials: PLA (simple), ABS (stronger), PETG (durable). Surface finish often requires extensive sanding.

- SLA/DLP (resin printing): Great for highly detailed small parts (vents, connectors, weapons, sensor eyes). Produces smoother surfaces and finer details, ideal for model kits. Materials: Standard resin for details, tough resin for stress points.

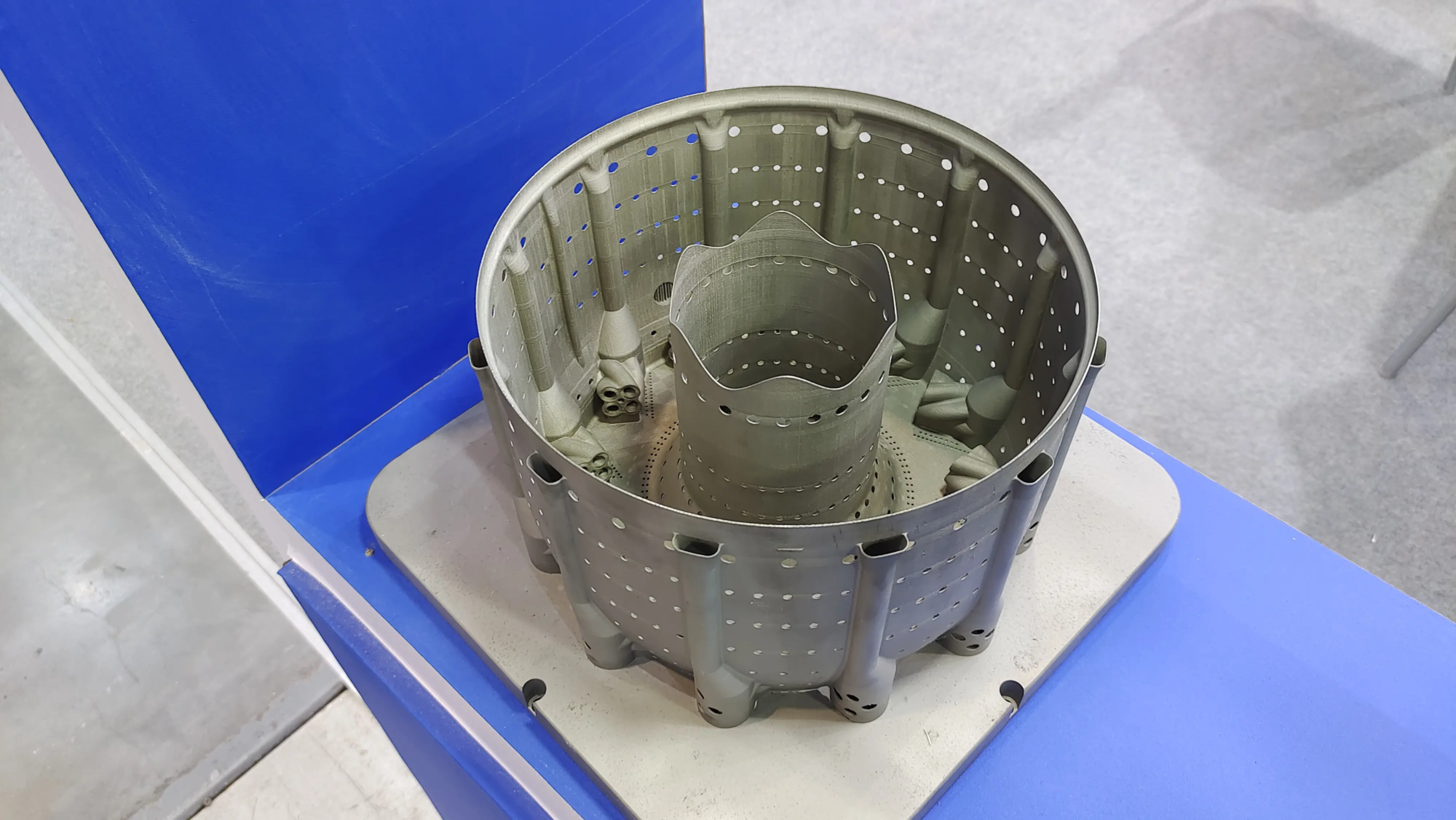

- Metal Parts (Professional Services – GreatLight Advantage): Metal 3D printing via SLM (Selective Laser Melting) or other advanced metal additive manufacturing processes is critical for parts that require superior strength, weight, heat resistance or metal aesthetics (e.g. frame components, joints, thrusters, precision weapons). This is where professional manufacturers shine.

- GreatLight’s SLM (Selective Laser Melting): Our state-of-the-art SLM equipment uses high-power lasers to fuse fine metal powders (such as aluminum alloys, stainless steel, titanium) layer by layer. It creates fully dense, high-strength metal parts with excellent resolution for demanding model kit assemblies. Crucially, we can handle complex post-processing (support removal, heat treatment, precision machining, polishing or surface finishing) to ensure your metal parts are ready to go beyond DIY capabilities.

- Why metal is important in Gunpla: Enhanced realism (real metal look/weight), critical joint strength, wear resistance, and superior dimensional stability of complex mechanisms.

- Plastic Parts (Home Printing):

-

Perfect printing and post-processing:

- Plastic (household): Careful slice setup (support, orientation) is crucial. Expect to spend a lot of time on post-processing: removing supports, sanding layer lines, filling gaps. Primer and spray paint are essential for a professional finish.

- Metal (GreatLight Services): By leveraging professional services, you can skip huge technical challenges print Make intricate metal parts with your own hands. GreatLight handles the entire production chain: expert SLM printing ensures optimal density and avoids warping/internal stresses, then advanced One-stop post-processing and finishing. This includes the following key steps:

- Supports CNC precision removal.

- Heat treatment (stress relief).

- Precision machining of critical mating surfaces.

- Polishing (Various Grades).

- Sandblasting, anodizing or electroplating to achieve the desired surface finish – all critical to a seamless fit and superior final appearance when integrated with plastic parts.

- Assemble and meet: Enjoy the familiar process of assembling your creations! Custom 3D printed parts, especially professionally fabricated metal components, often enhance the build experience and end result well beyond standard kits. Your vision becomes actionable.

Conclusion: Advanced Manufacturing Redefines Customization

3D printing has revolutionized Gunpla customization, going beyond decals and paint to allow for true structural and aesthetic transformations. While home plastic printing opens many doors, combining High-strength, precision metal parts Expert SLM printing services like those offered by GreatLight represent the latest technology.

As one of China’s leading rapid prototyping companies, Greite combines advanced SLM metal 3D printing technology with comprehensive post-processing expertise. Whether you need a custom knife handle with gleaming real metal, or intricate frame components engineered for a perfect fit and lasting strength, we provide reliable, high-quality solutions. We simplify access to industrial-grade metal additive manufacturing for enthusiasts who demand the highest precision and durability.

Ready to push the boundaries of Gunpla projects with custom metal parts?

FAQ: 3D Printed Gundam Model Kit

-

Can I print the entire Gundam kit?

- It is technically feasible, especially for smaller scale resin printing. However, it is very time-consuming and requires solving multiple complex design challenges (such as joint mechanisms). Most people print specific custom parts, weapons or mods to complement an existing kit or resin conversion kit.

-

Where can I find good STL files for Gundam parts?

- Check the private repository:

- universe of things

- Cult 3D

- my mini factory

- CG Trader

- Use specific search terms: "Gundam accessories STL," "mobile suit part," "[MS Name] conversion," "Gunpla custom parts." Please note that distributing exact replicas of official Bandai parts often violates copyright; original designs or modifications are your safest route.

- Check the private repository:

-

Do I need a very expensive 3D printer?

- For detailed plastic parts, mid-range resin printers (e.g. Elegoo Saturn, Anycubic Photon) work well. FDM printers require more skill and post-work to achieve a smooth surface. for metal partshome printing is impractical and expensive. Relying on professional SLM metal printing services like GreatLight is the only viable option, delivering industrial quality, material selection and critical post-processing.

-

Is 3D printing cost-effective compared to buying a kit?

- it depends. Printing small custom parts or replacement parts on resin can be very cheap. Using a professional service to print large or complex parts, especially metal parts, can get expensive. Its value lies in Uniqueness, customization and addressing specific needs (Repairs, Rare Parts) Mass-produced kits won’t work.

-

Why are metal parts used in most plastic models?

- Augmented Realism: Weapons, joints, thruster bells have real metallic weight and shine.

- Durability: Metal significantly increases the strength and wear resistance of critical high-stress components (joints, locks, weapons connections).

- Accuracy and Stability: SLM printed metal parts offer exceptional dimensional accuracy and thermal stability – crucial to ensuring perfect fit and functionality over the long term.

- How do I order custom metal parts from GreatLight?

- Upload your design: Provide us with your directly printable 3D model files (STEP, STL, etc.) through our platform.

- Material and process selection: Choose the best metal alloy (e.g. aluminum, stainless steel, titanium) based on functional, weight and cost requirements. We choose the appropriate SLM process.

- Quotation and confirmation: We analyze the files and provide a detailed quote including printing and post-processing options (machining, surface finish).

- Production: Our experts take care of SLM printing and all specified post-processing.

- Quality inspection and delivery: Parts undergo strict quality control before being shipped to you as kit components. Our services are designed to increase accuracy, speed and effectively solve complex prototyping challenges.

Unleash the potential for true customization in your Gundam builds. Combining the artistry of a hobby with the precision of advanced manufacturing. Customize your precision rapid prototyping parts now with GreatLight at the best prices!