Turn your passion into metal: 3D print your own Optimus Prime

The dream of having your own iconic Autobot leader, Optimus Prime, is no longer just for Cybertron’s elite. Thanks to revolutionary advances in 3D printing technology, specifically metal additive manufacturing, dedicated enthusiasts and collectors can now create personalized, highly detailed pieces of this beloved character. Forget cheap plastic trinkets—imagine a shape-shifting hero cast in premium metal that embodies strength, detail, and customization. While home printers have trouble handling tiny figurines, achieving a truly impressive, durable and potentially articulated Optimus requires upgrading to a professional-grade solution. This is where expertise like GreatLight comes into play.

Why Metal Optimus Prime? Beyond plastic toys

Authenticating Optimus Prime required durability to match his character. Plastic prints, while easy to work with, often lack weight, precise surface finish and long-term resilience. A show-worthy Optimus Prime – especially one designed with moving parts for transformation – benefits greatly from metal:

- Unparalleled Strength and Durability: Metals such as aluminum alloys or stainless steel have superior structural integrity compared to plastics. They resist warping over time, handle stress points (such as seams during deformation), and have a sturdy feel.

- Exquisite detail and surface finish: Advanced metal 3D printing processes, such as Selective Laser Melting (SLM), produce the extremely fine features necessary for the complex geometry of Optimus Prime’s armor, facial details, and complex weapons. Post-processing techniques unlock smooth surfaces or stunning multi-faceted looks.

- Customization King: Want a scale model? Unique color scheme? Functional joints? The choice of materials determines both aesthetics and functionality. Titanium offers an incredible strength-to-weight ratio, aluminum offers exceptional detail and workability, and steel offers unparalleled toughness. Professional services handle complex alloys seamlessly.

- The ultimate collectible: The metal-polished Optimus Prime transcends ordinary collectibles. It became a statement piece, showcasing the characters and the cutting-edge technology used to create them.

The journey: from digital dream to physical legend

Making Metal Optimus Prime wasn’t just a matter of urgency "Print." This is a multi-stage engineering and artistic process best handled by experts:

-

blueprint: Start with a high-quality digital model. Whether sourcing reputable STL files online or working with a designer for a custom interpretation (your unique truck pattern?), make sure the design is optimized for 3D printing. This includes complex internal transformation mechanisms.

-

Material selection: This is crucial. Discuss with an expert:

- Aluminum alloy (e.g. AlSi10Mg): The perfect balance between detail resolution, strength-to-weight ratio, workability for post-processing and cost-effectiveness for large models.

- Stainless steel (e.g. 316L): Excellent toughness, corrosion resistance and impressive polishing surface potential.

- Titanium alloys (e.g. Ti6Al4V): Aerospace grade strength, superior fatigue resistance and unique aesthetics (non-porous surface after polishing), this is the perfect choice when extreme durability and significance are critical.

- Tool steel: Ideal for demanding applications requiring wear resistance.

(At GreatLight, virtually any applicable metal alloy can be sourced and machined to your unique requirements.)

-

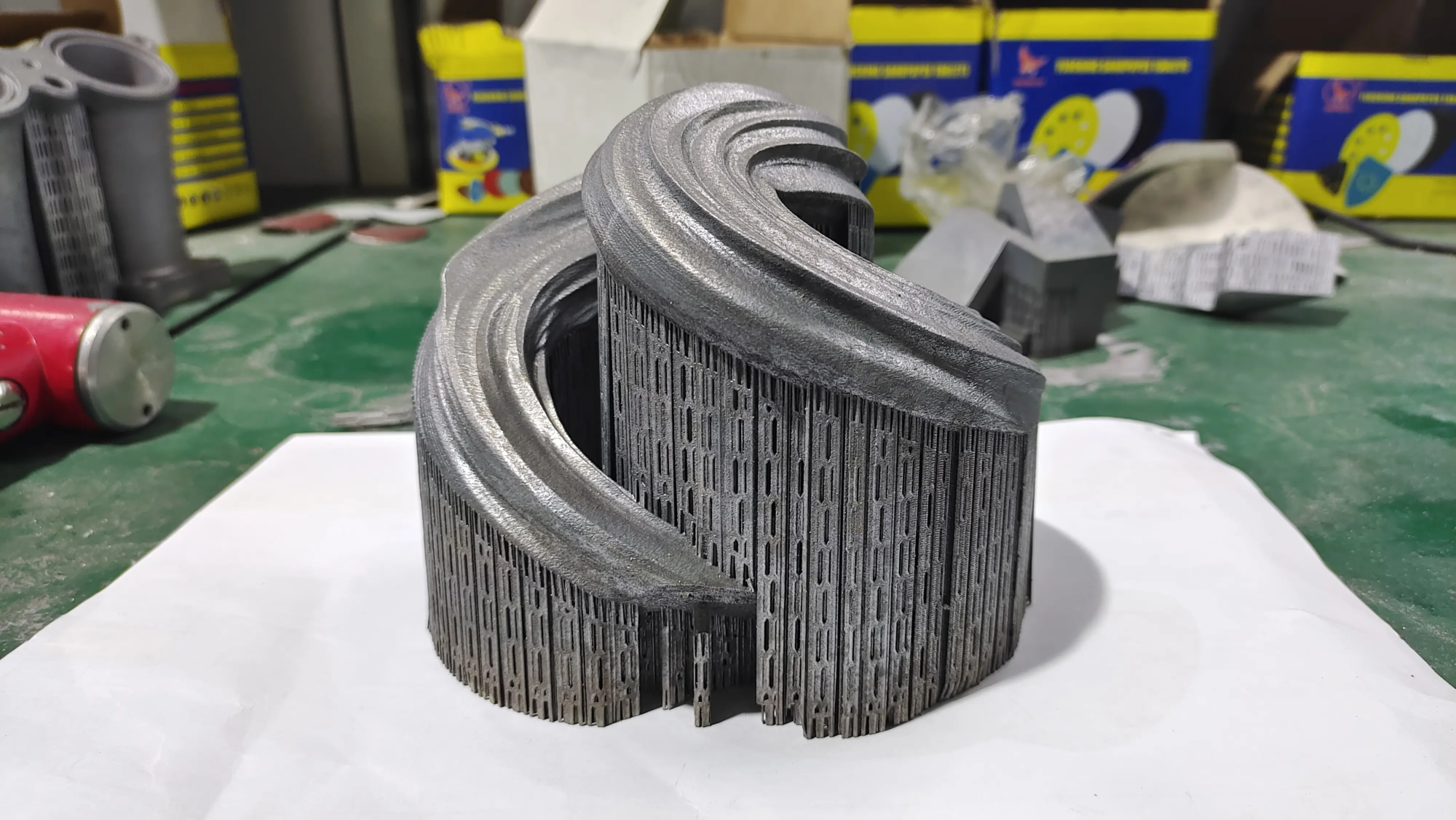

furnace: Printing complex forms with Optimus – This is where SLM technology shines. High-power lasers precisely melt metal powder layer by layer, creating complex geometries not possible with traditional machining. Professional SLM printers ensure:

- accurate: Maintaining tight tolerances is critical for articulated joints and complex assemblies.

- Reduce risk: Expertise minimizes issues such as warping, cracking or removal of complex support structures inherent in metal printing.

- Unleash the charm of art: post-processing: Your Optimus transforms from printed shape into masterpiece:

- Support removal: The intricate structures used to support the overhangs are carefully removed during the printing process – delicate work requires experience.

- Surface treatment: Sand, sandblast, polish (mirror or satin) or CNC machine to obtain desired surface texture – smooth curves, crisp edges.

- assembly: Precisely assemble parts, paint or customize plating (such as chrome effects), add decals – turn the assembly into a cohesive, stunning graphic.

Why work with a professional rapid prototyping manufacturer like GreatLight?

Home printers and online agencies specializing in basic plastics are working hard to meet the demand for functional metal Optimus Primes. GreatLight specializes in solving these complex challenges:

- Industrial SLM Power Source: Use cutting-edge metal 3D printers that can reliably handle complex geometries and demanding materials.

- Integrated end-to-end service: We handle every step: design consultation optimization, precision metal printing, expert post-processing (support removal, advanced CNC machining, fine polishing, custom plating/painting) and final assembly. You get a seamless experience.

- Material experts: Extensive knowledge in selecting and processing the best metal alloy to suit your vision, whether that prioritizes weight (titanium), detail/balance (aluminum), toughness (steel) or custom attributes.

- Solution-focused: We solve complex rapid prototyping problems every day. Overcome overhang, minimize internal stress, and ensure dimensional accuracy of complex shapes? This is our core competitiveness.

- Speed and efficiency: Leverage optimized processes quickly Turnaround, bypassing lengthy traditional manufacturing bottlenecks.

in conclusion

Owning a custom metal Optimus Prime is more than just owning a collectible; It’s about leveraging cutting-edge manufacturing technology to realize one’s personal vision. Intricate detail, satisfying metal weight, and the potential for interactivity represent the pinnacle of what modern additive manufacturing can achieve for passionate creators. While ambition begins with your imagination, its successful metal incarnation relies heavily on expertise.

Build your legend. Partner with GreatLight—leveraging our industrial SLM capabilities, deep materials knowledge, and comprehensive one-stop finishing services—to transform your Optimus Prime dream from a digital vision into an extraordinary, physically strong metal reality. As precision becomes more affordable, personalized Optimus is ready to roll out.

FAQ: Answers to your Optimus Prime 3D printing questions

Q1: Can GreatLight print complete images? change Metal Optimus Prime?

Answer: Of course! This is where design optimization and high-precision metal printing come into play. We can print the complex interlocking components required for retrofits and facilitate expert assembly. Upfront design consultation is critical to ensure structural integrity and smooth movement.

Question 2: Which metal is best for my Optimus Prime project?

Answer: There is no single "the best," it depends:

- Highly detailed and balanced: Aluminum alloys (e.g., AlSi10Mg) are usually ideal. Excellent detail capture, good strength to weight ratio, excellent post-processing machinability, often cost effective for prototypes and models.

- Ultimate Strength/Accuracy: Stainless steel (such as 316L) has excellent toughness and an investment cast-like finish when CNC milled/polished.

- Aerospace Performance/Reputation: Titanium (Ti6Al4V) offers an unparalleled strength-to-weight ratio and corrosion resistance for truly premium results. Discuss your primary goals (display, clarity, material feel) and budget with our engineers.

Q3: What tolerance can the SLM printed mechanism achieve?

A: The industrial SLM system used by GreatLight can achieve dimensional tolerances typically in the range of +/- 0.05 mm to +/- 0.1 mm on key features. Combined with expert post-machining of mating surfaces, this results in smooth-operating articulated joints, which is crucial for transforming figures.

Q4: What is "One-stop post-processing" include?

A: We will take care of everything after printing is complete:

- Safety support structure removed.

- Heat treatment (stress relief/annealing) if required.

- CNC machining is used for precise mating surfaces, holes or finishing.

- Surface smoothing: grinding, sandblasting, polishing (manual or CNC automatic).

- Custom Finishes: Paint (primer/primer/clearcoat), plating/anodizing options, special coatings.

- Final quality inspection and assembly.

Q5: Can I really customize unique features or materials?

Answer: Yes! Customization is our specialty. In addition to standard alloys, we can also explore specialty materials. Want unique joint mechanisms, scaled-down versions, specific color schemes or plating? We work closely to refine your design and material selections to make your unique Optimus vision tangible.

Q6: How long does a typical Metal Optimus Prime project take?

A: Delivery times vary greatly depending on complexity, size, materials, finish selected and assembly complexity. Simple display models may be ready in a few weeks. Complex, highly detailed morphing characters that require extensive post-production may take even longer. We prioritize transparent timelines when quoting. Contact us for a personalized estimate on your project blueprint!

Q7: Why choose GreatLight instead of a local FDM printer or a universal online service?

Answer: Complexity requires specialization. Off-the-shelf services focused on plastics or low-resolution metals do not provide the dimensional accuracy, material properties, surface finish or comprehensive expertise required for high-quality metal Optimus. GreatLight combines advanced SLM printing, in-depth metallurgical knowledge and the exquisite art of finishing to specialize in precision metal prototypes and complex custom parts like yours. We solve difficult problems. Tell us your boldest visions for Optimus Prime, and let’s change them together.