Unlock the impossible: 3D print your own metal teleporter gun

Ever gazed longingly at Valve’s iconic Aperture Science handheld portal device Portal series and wish it wasn’t limited to the digital realm? Thanks to the revolutionary capabilities of metal 3D printing, transforming this sci-fi marvel into an accessible, awe-inspiring prop is no longer science fiction. While plastic 3D printed replicas abound, the true majesty, icy heft and intricate detail of the teleporter gun required the strength and finish of metal. This is where advanced additive manufacturing, and specifically Selective Laser Melting (SLM), comes into focus and expertise becomes critical.

The Allure of Metal: Beyond Plastic Prop Replicas

Plastic-printed teleporters can make for fun display pieces, but they often lack the authenticity that hardcore fans crave. Metal Fabrication perfectly captures the essence:

- Real weight and feel: Aluminum or stainless steel offer a satisfyingly solid weight that plastic simply cannot match, reflecting the imagined weight of a device capable of bending space and time.

- Superior detail fidelity: SLM technology excels at producing complex geometries – curved casings, internal channels, intricate trigger mechanisms, and the Portal Gun’s unique central core casing can all be rendered with stunning accuracy.

- Durability: The Metal Portal Gun isn’t just a prop; This is a timeless artifact. Metal is more resistant to accidental bumps, deformation, and weather changes than plastic.

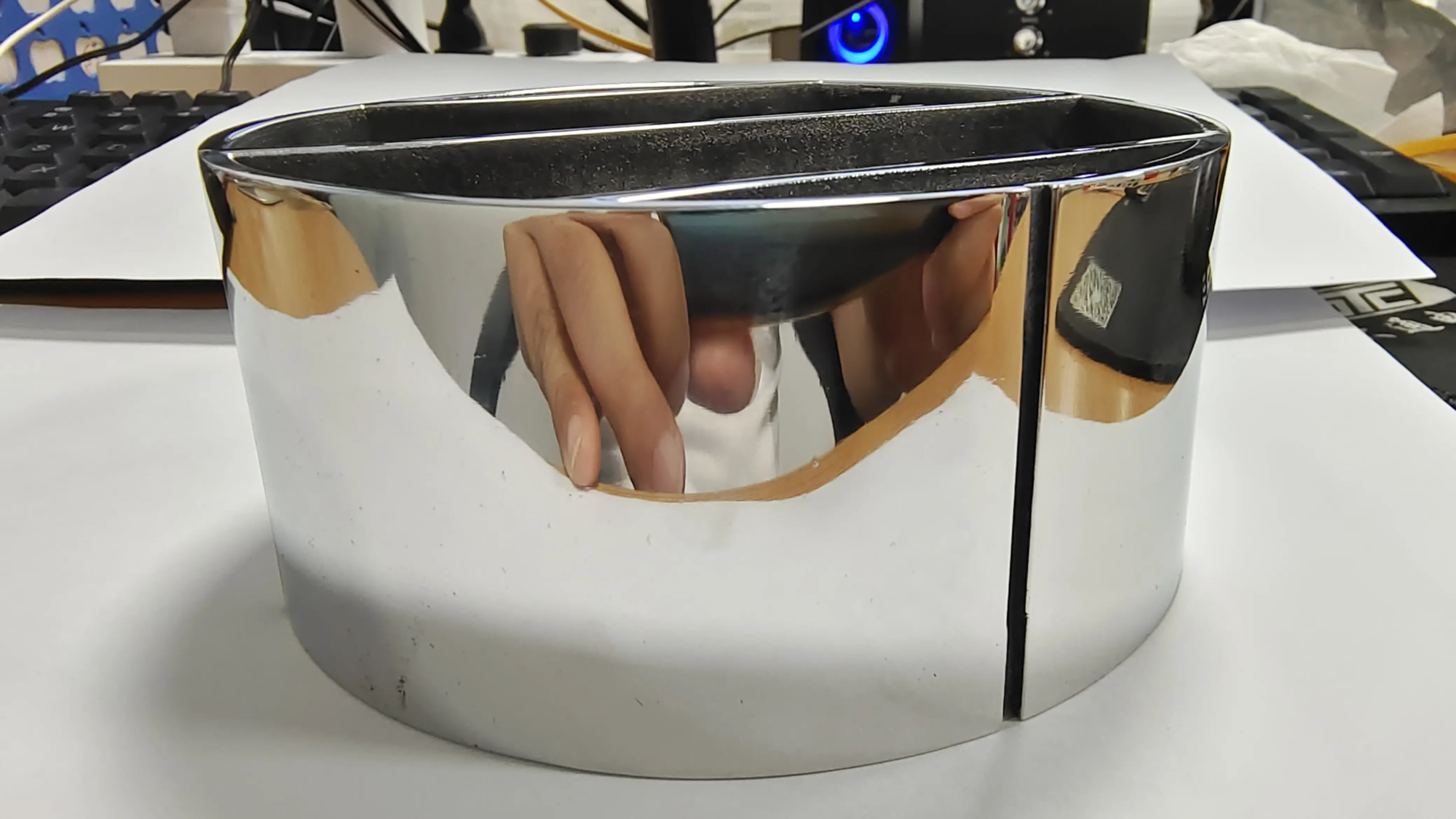

- Premium aesthetics: Post-processed metal surfaces (polished, sandblasted, anodized or painted) provide a professional, high-end finish that elevates replicas from hobby projects to museum-quality display pieces.

Dealing with Complexity: Why This Is Not Your Ordinary Print Job

There are significant obstacles to printing a functional (or even completely non-functional) teleporter gun in metal:

- Design optimization: Converting game models into manufacturable CAD files requires engineering insight. Part design must take into account SLM constraints: overhanging support structures, minimizing internal stresses and ensuring wall thickness is appropriate for the chosen metal. Components often need to be strategically segmented for printability and assembly.

- Sustainable land management expertise: This is not plug and play. SLM involves using a high-power laser to melt fine metal powder layer by layer. Parameters such as laser power, scan speed, fill pattern, layer thickness and air flow must be carefully controlled by experienced technicians. Thermal management is critical to preventing warping or cracking, especially in large, complex parts like gun body casings.

- Material challenges: Different metals (AlSi10Mg for lightness and detail, stainless steel 316L for strength and corrosion resistance, maybe even titanium for ultimate bragging rights) behave differently during the printing process, requiring customized parameter sets.

- Post-processing commands: Original SLM parts are just the beginning. This is where comprehensive services become critical: Supports must be removed carefully (a delicate task to avoid damaging the part), the surface requires extensive finishing (machining, grinding, polishing, tumbling) to remove layer lines and achieve the desired aesthetics, and potential heat treatment may be required to relieve stresses or enhance material properties. Electronic integration (LEDs, sound modules) requires precise design of cavities and mounting points.

The GreatLight Advantage: Your Portal Creation Partner

Taking a metal portal gun from fantasy to reality requires more than a 3D printer; it requires cutting-edge equipment, deep technical mastery, and a holistic approach. This is at the core of Honglaite’s expertise as a leading professional rapid prototyping manufacturer.

- Advanced SLM arsenal: We deploy state-of-the-art selective laser melting systems capable of processing complex geometries and large-scale builds with micron-level precision—critical to the Portal Gun’s unique curves and fine details.

- Material mastery: From lightweight aluminum alloys for main frames to rugged stainless steel for structural components, we offer a variety of customizable metal powders along with proven parameters for successfully printing them.

- End-to-end solution: GreatLight is about more than just printing. we provide One-stop post-processing and finishing services Under one roof. Our team specializes in:

- Precise support structure removal.

- Comprehensive surface treatment (including sandblasting, CNC machining of critical interfaces, hand polishing).

- Custom coating (anodizing, plating, professional painting).

- Heat treated and stress relieved.

- Quickly customize and resolve issues: Is a specific alloy required? Need to modify the internal electronics? Facing a complex geometry challenge? Our engineering team specializes in rapidly prototyping custom metal solutions. We focus on professionally solving complex metal parts rapid prototyping problems quickly and efficiently.

- Quality and precision: As one of China’s premier rapid prototyping companies, we prioritize dimensional accuracy, structural integrity and surface quality to transform concepts into high-quality metal masterpieces. Custom precision machining capabilities complement our SLM work to ensure components fit perfectly.

The journey from CAD to handheld wonders

- Digital Genesis: Start or commission an accurate, print-ready CAD model optimized for metal SLM. Consider features like removable triggers or lighting (design space for wires/batteries).

- Expert consultation: Cooperate with Gretel. Our engineers will review the design for manufacturability, recommend optimization for strength and print success, and guide material selection.

- SLM manufacturing: Your design is rigorously digitally sliced and parameterized. Our SLM printers carefully fuse metal powder into solid parts under a controlled atmosphere.

- Comprehensive post-processing: Parts undergo support removal, surface smoothing and any required precision machining. Adapt parts with different finishes (e.g. polished chrome barrel vs. matte black grips) accordingly.

- Assembly and finishing touches: Clean and finished parts are carefully assembled. Electronics, if any, are integrated. A final coating (paint, varnish) is applied to provide protection and a perfect Aperture Science look.

- Realistic implementation: Hold on for the impossible; a stunning custom metal portal gun ready for your enchantment.

in conclusion

The 3D printed metal delivery gun pushes the boundaries of hobbyist manufacturing into high-end professional prototyping and manufacturing. The ability of SLM technology to produce complex metal geometries combined with an essential suite of expert post-processing services made this iconic prop a reality. While challenging, the result – a thick, detailed, durable and visually stunning replica – is unparalleled. Work with experienced rapid prototyping manufacturers such as huge light More than just an advantage; it’s often an important link between ambition and achievement. We have state-of-the-art equipment, SLM expertise, comprehensive finishing capabilities, and a commitment to solving complex metal prototyping challenges to transform your vision of a true Aperture Science wonder into solid metal glory. Rediscover your passion for gaming in exceptional quality items.

FAQ: 3D Printed Metal Delivery Gun

Q1: Can GreatLight print complete images? functional Can a portal gun open a portal?

A: While technically fascinating, creating a device to manipulate space and time remains firmly within the realm of theoretical physics! Honglaite focuses on high precision Non-functional replicas and props. We focused on achieving the exact look, weight, feel and intricate exterior details of the teleporter gun. any "Functional" are for aesthetics (like LED or sound modules) rather than actual portal creation.

Q2: Is this price very expensive? How much does a metal teleporter gun cost?

A: Metal 3D printing with complete post-processing is a premium service compared to plastic printing or ready-made props. The cost depends largely on Dimensions, selected materials (aluminum is generally more cost effective than stainless steel or titanium), Model complexity (number of parts, internal details), Required post-processing completed (simple sandblasting and mirror polishing), and quantity (One-off vs. small batch). Contact GreatLight with your specific quote specifications and take advantage of our customizable and Competitive price Rapid prototyping.

Q3: Do I need to provide CAD files, or can FeiLite design it?

A: We offer flexible services! If you have a printable, optimized CAD file, we can manufacture it. If you need design help – whether creating a model from scratch from a reference, reverse engineering an existing model, or optimizing an existing file for SLM printing – GreatLight’s engineering team is available Custom design support as part of our prototype solution.

Q4: What metals are suitable and which ones do you recommend?

A: The most common options are:

- AlSi10Mg (aluminum alloy): An excellent choice for most components. Light weight, good strength-to-weight ratio, excellent for capturing fine details, and high cost performance. Suitable for main housing and non-load-bearing parts.

- Stainless steel (316L): Provides greater strength, weight and corrosion resistance. Ideal for structural support, triggers or when a heavier feel is desired. More challenging than aluminum in terms of detail.

- Titanium (Ti6Al4V): Premium options offer superior strength while being lighter than steel and offering excellent corrosion resistance. The highest cost and best suited for customers where the credibility of the final material is key.

GreatLight can provide recommendations on the best materials for your specific priorities (budget, weight, appearance, level of detail).

Q5: How long does the whole process take?

A: Time frames vary based on design complexity, size, materials, post-processing finish selected and current workload. Considering print times and careful post-processing steps, complex aluminum models with multiple surface treatments can take weeks from final CAD to shipment. Velite specializes in Quick turnaround time Prioritize efficiency over project scope without compromising quality. Get project-specific timelines during quotes.

Q6: How durable is the metal 3D printed delivery gun?

Answer: More durable than similar plastic products! Metal parts produced by SLM have excellent material density and strength. While it’s still a display piece and not meant for rough handling like a real tool, it resists accidental bumps, temperature changes, and UV degradation better than plastic. Premium post-treatment further enhances surface integrity.

Q7: Is Huilite responsible for the final assembly and painting?

Answer: Of course! our One-stop service Includes assembly inspection prior to installation. If multiple moving parts are involved, complex final assembly may be handled by the customer, but we provide the necessary subassemblies and ensure the components fit precisely. Crucially, we offer a comprehensive Organizing servicesincluding professional-quality painting to match Aperture Science’s signature orange/white/black scheme or custom colors. We can also apply a clear coat for protection.