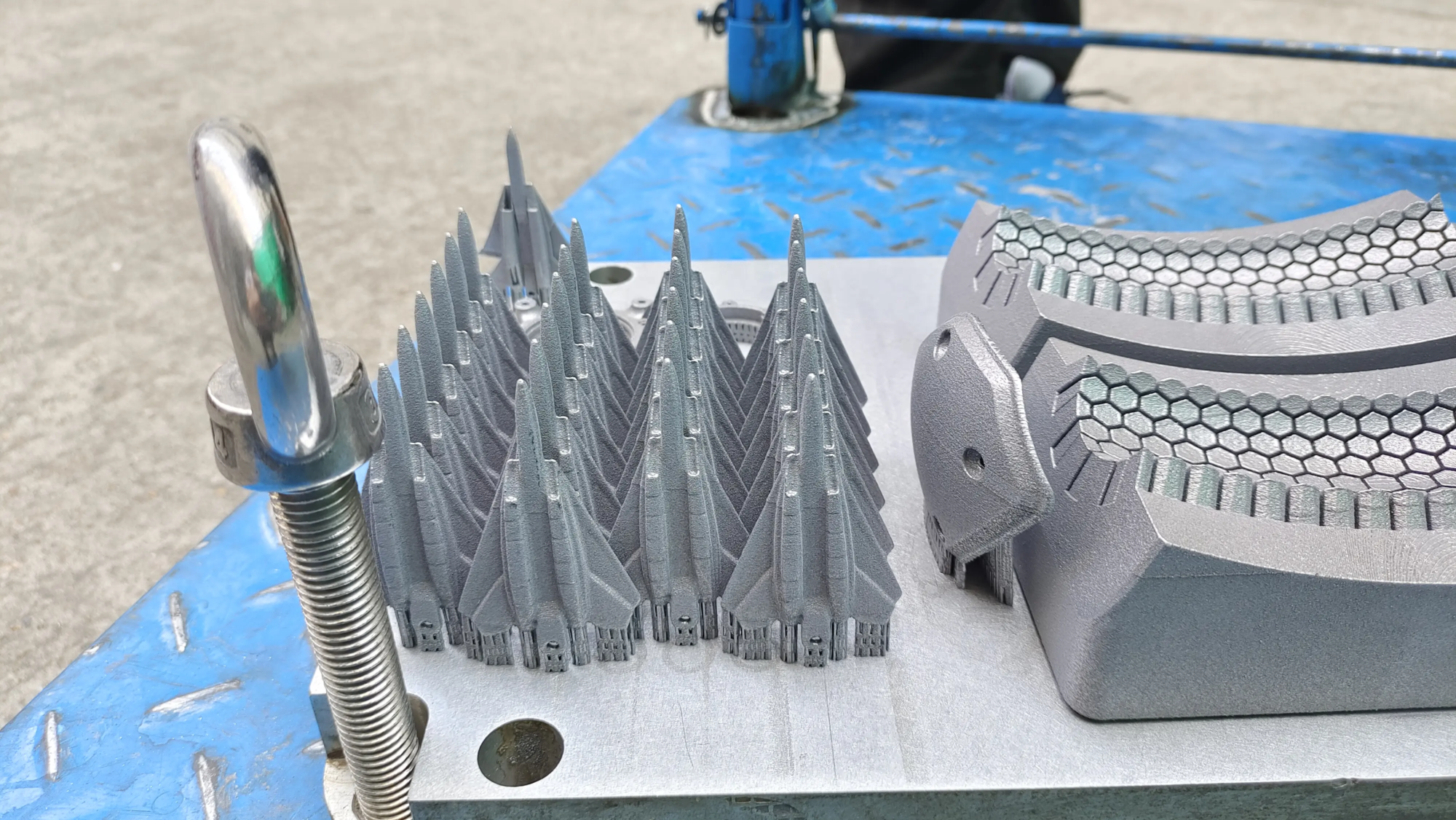

As a leading rapid prototyping manufacturer, Greatlight has been at the forefront of innovation, leveraging cutting-edge technology to provide first-class solutions for rapid prototyping of metal parts. With advanced SLM 3D printer equipment and production technology, the company has been successfully solving complex metal parts prototype problems, providing one-stop post-processing and completion services to meet the various needs of customers. The ability to customize materials and quickly handle them is an important advantage, and it is one of the best rapid prototype companies in China.

The introduction of 3D printing revolutionized the manufacturing industry, thus enabling the creation of complex geometric shapes and structures that were previously unproductive by traditional methods. One of the most important applications of 3D printing is to create 80/20 panels. These panels, also known as T-Slot panels, are widely used in a variety of industries including aerospace, automotive, and industrial automation due to their versatility, durability and ease of use.

3D printed 80/20 panels offer a variety of benefits, including rapid production, reduced material waste, and improved design flexibility. Traditional manufacturing methods (such as CNC machining) can be time-consuming and expensive, especially for complex designs. By contrast, 3D printing allows for rapid production of 80/20 panels with complex geometries and custom designs, reducing lead time and cost.

Using 3D printing technology can also create custom 80/20 panels with specific material properties, such as strength, durability, and thermal resistance. This is especially important in industries where panels are subject to severe environments or extreme temperatures. Additionally, 3D printing allows multiple components to be integrated into a single panel, reducing assembly time and increasing overall system efficiency.

Greatlight’s expertise in 3D printed 80/20 panels enables the company to provide innovative solutions for various industries. Focusing on precision, quality and customer satisfaction, Greglight is a trusted partner for companies seeking custom-made rapid prototype services. The company’s commitment to using only the highest quality materials and state-of-the-art equipment ensures that the final product meets the strictest standards.

In short, 3D printed 80/20 panels have revolutionized the manufacturing industry, providing rapid production, reducing material waste and improving design flexibility. Greatlight’s expertise in this area allows the company to provide innovative solutions to various industries and become a trusted partner for companies seeking custom-made rapid prototype services. Focusing on precision, quality and customer satisfaction, Gremplight is expected to continue to push the possible boundaries of 3D printing technology.

FAQ:

Q: What is 3D printing and how does it work?

A: 3D printing is a manufacturing process that creates objects through materials such as metals, plastics and ceramics based on digital models, such as metals, plastics and ceramics. The process involves the deposition of a layer of material to create the final product.

Q: What are 80/20 panels and what are they used for?

A: 80/20 panel, also known as T-Slot panel, is widely used in a variety of industries including aerospace, automotive and industrial automation due to its versatility, durability and ease of use. They are used to create frames, mounts and other structures for a variety of applications.

Q: What are the benefits of 3D printing 80/20 panels?

A: The benefits of 3D printing of 80/20 panels include rapid production, reduced material waste, and improved design flexibility. This creates complex geometry and structures that were previously unavailable by traditional methods.

Q: Can Greatlight customize the 80/20 panel to meet specific requirements?

A: Yes, Greglight can customize 80/20 panels to meet specific requirements, including material properties such as strength, durability, and thermal resistance. The company’s expertise in 3D printing enables the creation of custom panels with complex geometric shapes and designs.

Q: What is the delivery time for 3D printed 80/20 panels?

A: The lead time of 3D printed 80/20 panels depends on the complexity of design and production. However, Greatlight’s state-of-the-art equipment and expertise enable rapid production, reducing lead time and cost.

ISO 9001 Factory