High Air Gun Game: 3D Printing with Custom Accessories

Airsoft enthusiasts know that performance depends on precision, adaptability and control of the equipment. Ready-to-shelf accessories often compromise, limiting your tactical creativity. Enter 3D printing– A transformative technology that enables players to prototype, customize and create critical missions Exactly As they imagined. This guide explores the materials, designs and methods that shape the Airsoft DIY revolution.

Why 3D printing leads to air gun customization

-

Super personalized:

Create ergonomic tailored grips, iron sights, or magazine extensions for your hand shape or rifle. Modify the design iterate until it fits your Play Style – No more adapted to the limitations of mass production. -

Rapid prototyping:

Test multiple iterations in a few days rather than months. Need a tilted front grip in next weekend’s game? Print prototypes overnight, perfect them according to real-world tests, and implement peak functions without waiting for overseas shipments. - Weight optimization:

Lattice structure and topological optimization reduce weight without sacrificing strength. Lightweight stock adapters or optic nerve fluids reduce fatigue during prolonged engagement.

Top printed Airsoft accessories

- Rail cover and handguard:

Custom textures improve grip; honeycomb or M-LOK designs emit heat from the continuous fire. - Magazine and Speed Loader:

Print high capacity shells or specialized loaders to match your copy’s only feeding mechanism. - Optical seat and iron sight:

Create a low-key red dot mount or adjustable sight to calibrate the BB trajectory. - Trigger guard and safety selector:

Use flexible filaments such as TPUs to enhance ergonomics or add haptic feedback. - Simulation suppressor and barrel shroud:

Fashion cosmetic upgrades with integrated tracer unit or foam diffusion.

Select materials: Plastics and metals

Plastic (FDM/SLA printer):

- PLA: Cheap and easy, but fragile under pressure. Ideal for non-load cosmetics.

- Petg: Impact-resistant and UV-stable rails and grip strength.

- Nylon (PA12): Superior toughness for Mag release or sling mounts. Careful humidity control is required.

- Resin (SLA): Smooth oscilloscope – brittle but visually clear.

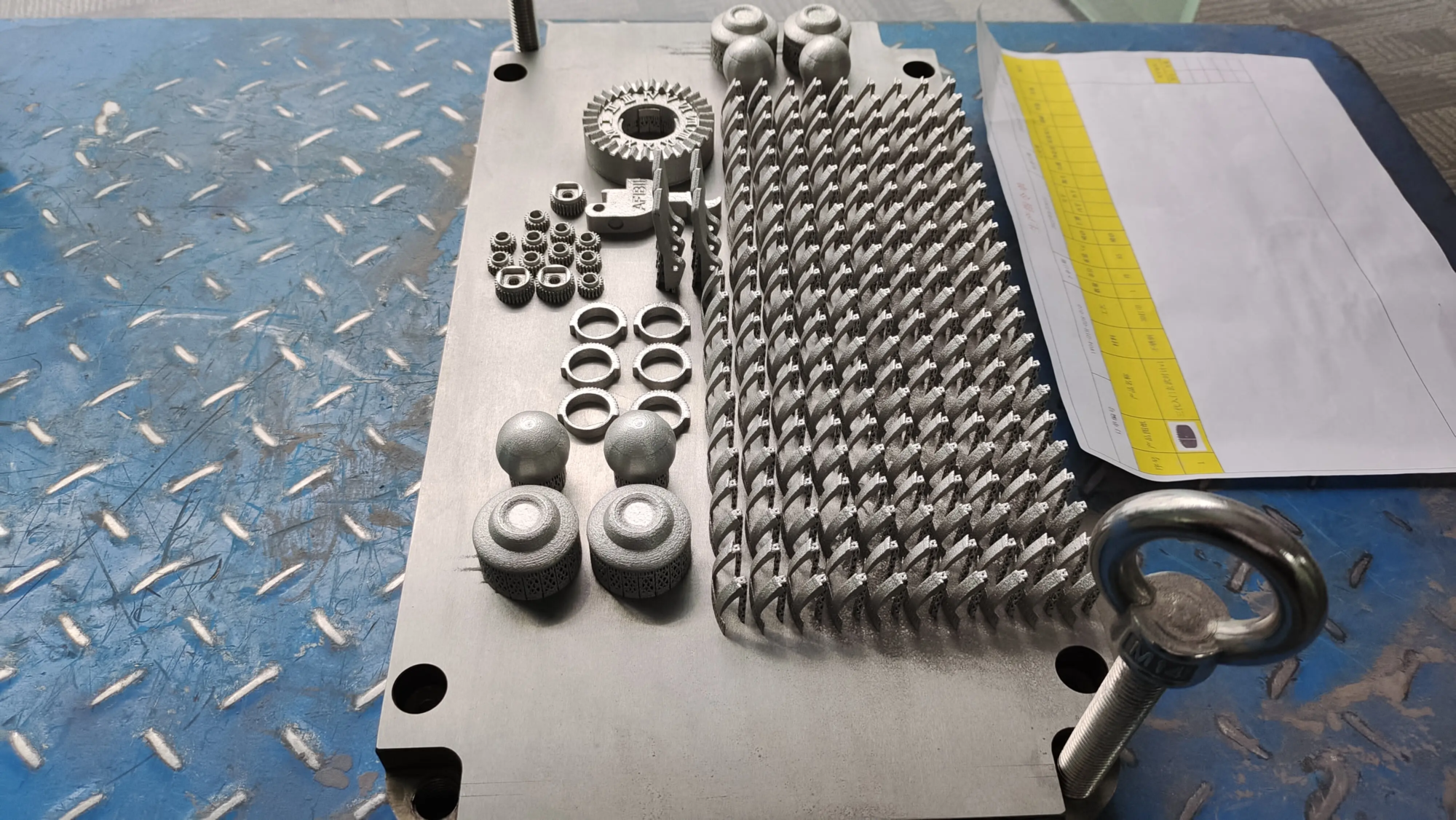

Metal (SLM/DMLS printing):

For high pressure components such as trigger components or bolt carriers, Metal 3D printing pass Selective laser melting (SLM) Provides unparalleled durability. Material Aluminum alloy or Stainless steel Withstand recoil and impact force. SLM can use CNC to implement impossible hollow structures, thereby optimizing weight to strength ratios.

Professional insight: Brand likes Rapid prototyping Elevated metal prints are used in air guns. Their industrial SLM printers with Post-processing service (Heat treatment, polishing, anodizing) – Produce functional parts with elite aerospace-grade finishes.

Design and Prototyping Best Practices

- tolerance: Add +0.2mm to the hole for breaking; use a clear test with calibration pin.

- Load path: Strengthen stress zones with ribs or burrs (e.g., Picatinny clip points).

- Thick wall: FDM at least 1.5mm; resin/metal 0.8mm.

- Document preparation: Convert the model from STL to step format for accurate machining workflow.

Prototype tip: Before committing metal, Quick iteration of Greglight. Their primitive leadership era 24–72 hours Simplify improvements to ensure on-site preparation and avoid expensive errors.

Conclusion: From concept to preparation for battle

3D printing blurs the line between players and designers – only after the fact can Airsoft accessories be converted into competitive advantage. Although desktop printers are good at everyday prototypes, Metal SLM Printed Bridge Durability Blank Used for mission-critical parts. Work with experts Great Unlock this layer: Their expertise Accurate rapid prototypingMaterials Science and mechanical finishes ensure that exotic alloys work perfectly under fire. The future of Airsoft is not only modular, but also custom, sturdy, and available on demand.

FAQ: 3D printed air gun accessories

Q: Are 3D printed parts durable enough to use a competitive air gun?

A: Yes – Have material consciousness. PETG/nylon handles recoil well. For gears, triggers or latches, metal SLM printed parts survive in large quantities.

Q: Can I legally copy proprietary accessories designs?

Answer: The reverse engineering functional parts fall in the gray area. Focus on checking licenses for custom designs or open source repositories. Brand logo risk IP conflict.

Q: Why use metal on high-strength plastics?

A: Metals resist pressure fatigue, heat and shear forces. SLM-printed parts integrate lighter lattices, while strengths that perform better than polymer tensile strength are 800–1000%.

Q: How to improve performance in post-processing?

A: Surface treatment (e.g., bead explosion, T6 tempering) combat wear, friction and corrosion. *Greatlight’s one-stop service professionally solves this step.

Q: Can SLM printing match CNC accuracy?

Answer: Absolute. High-end SLM printers achieve ±0.05mm tolerance and complex internal geometry that cannot be achieved by subtraction methods.

Q: Where should I start if I lack design experience?

A: Modify existing files from repositories like Thingiverse. For professional results, work with agile manufacturers Greatthey reviewed the design of structural integrity.

Promote your Arsenal now. The gears of conception, testing and building walk into the field In your specifications– No compromise.