Improve your charging habits: unleash your creativity with a 3D printed Apple Watch stand

Forget the mess of cables and the hassle of finding a place to charge your Apple Watch every night. The world of 3D printing has revolutionized everyday accessories, and the Apple Watch charging stand is a perfect example. 3D printing combines personalized design, precision engineering and sheer convenience, allowing you to create or purchase a one-of-a-kind exhibition stand. Let’s dive into inspiring ideas and discover why 3D printing, especially metal printing, is uniquely suited for makers or anyone looking for custom solutions from experts like GreatLight.

Beyond Hockey: The Promise of Personalized Charging

The standard Apple Watch charging tray works, but lacks elegance and stability. Well-designed exhibition stand:

- Improve your watch: Literally and figuratively. It transforms charging from a necessity into a moment worthy of display.

- Organize your space: Integrate your charging locations—watch, iPhone, maybe AirPods.

- Protect your gear: The sturdy base prevents the bedside table from accidentally falling.

- Add personality: Express your style, from minimalist to futuristic, whimsical to high-end.

Ignite inspiration: categories of 3D printed exhibition stand designs

-

Minimalist single: Simplicity comes first. Think elegant arcs holding the puck at the perfect angle, a sleek geometric base, or a compact base that independently supports the watch. Perfect for bedside table or desk. Metal printing shines here, giving these ultra-thin designs a premium feel and exceptional durability, eliminating the brittleness sometimes found in thin plastic printing.

-

Dynamic duo: For those who are deeply entrenched in the Apple ecosystem. Designed to seamlessly integrate iPhone and Apple Watch charging functions. These range from clever stacking designs to L-shaped bases and elevated platforms. Stability is crucial here, Especially when accommodating heavier phones. Metal printing provides the multi-device stand with unparalleled structural integrity, ensuring it won’t wobble even under the weight. Companies like GreatLight that specialize in rapid prototyping are adept at leveraging the inherent advantages of metal printing to create structurally optimized designs.

-

Architectural explanation: This is where 3D printing really shines. Imagine this:

- Move your arms: Adjustable support arms hold the puck in place, allowing you to perfectly adjust the dial angle while charging.

- Balanced housing: An elegant casing surrounds the disc and MagSafe charger element for enhanced safety and aesthetics.

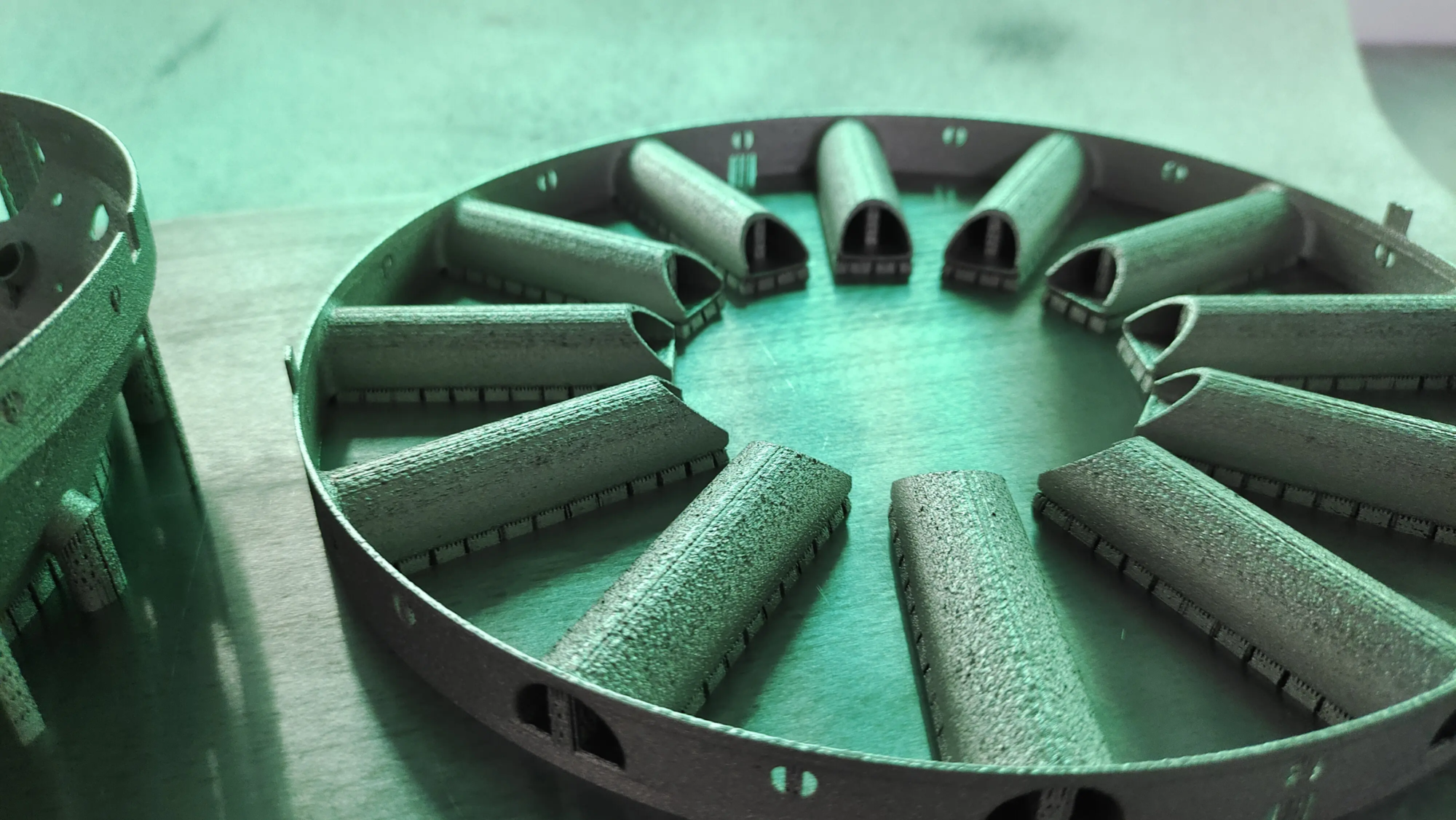

- Complex geometric shapes: Organic forms, complex lattice structures or designs inspired by nature – the possibilities are limited only by imagination. Achieving these often delicate, complex, high-strength shapes requires advanced printing technology. Selective laser melting (SLM) used by metal parts suppliers like GreatLight is ideal for precisely creating these complex and strong structures.

- Functional form: In addition to charging, the following functions are also integrated:

- Storage compartment: For spare strap or ring.

- Cable management: Built-in channels or pulleys for an original look.

- Weighted base: Ensure absolute stability. Metal printing inherently adds significant weight, making large plastic bases filled with sand obsolete.

Why choose 3D printing? Especially metal?

- Unparalleled customization: Customize every aspect (size, color, shape, functionality) to your exact preferences or brand aesthetic. Need customized corporate gifts? complete.

- Design freedom: Create internal meshes, hollow sections for weight reduction/enclosure, and organic shapes not possible with traditional manufacturing.

- Iterate quickly: Prototyping and design adjustments happen very quickly. GreatLight specializes in quickly converting CAD concepts into tangible parts to accelerate product development.

- Material advantages (especially metals):

- ULTIMATE DURABILITY AND STABILITY: Metals (such as aluminum alloys, stainless steel, titanium) can withstand impact and wear better than plastics, which is critical for items that are handled frequently. Its weight ensures rock-solid stability.

- Premium aesthetics: Metal provides a refined, high-end finish. Polished, sandblasted, anodized or electroplated options can significantly enhance the appearance. This organization is often seamlessly integrated with GreatLight’s turnkey prototyping solutions.

- Heat resistance: Metal can handle the small amounts of heat generated when electronic devices charge without deforming or degrading.

- Strength to weight ratio: Metal printing allows for stronger, thinner walls compared to plastic.

Work with the Experts: GreatLight Edge

Creating a functional, beautiful and durable charging stand (especially a metal one) requires expertise:

- Advanced equipment: Continuously produce complex metal parts with cutting-edge SLM printers optimized for precision and reliability.

- Materials Science: Understanding metal powder properties, melting characteristics and post-processing ensures optimal part quality and performance. GreatLight handles this complexity expertly.

- Precision Engineering: The design for additive manufacturing (DFAM) was critical to the dimensional accuracy, cable routing and structural integrity of the pocket that holds the puck. Professional prototyping ensures tolerances are reliably met.

- End-to-end service: From initial design consultation to prototyping, final production and expert finishing (polishing, coloring), a true partner like Gretel handles the entire process safely and efficiently.

in conclusion

3D printing transforms the humble Apple Watch charger dock from a practical tool into an opportunity for personalized elegance and functional innovation. Whether you are a hobbyist exploring PLA designs or seeking a durable, high-quality metal masterpiece, additive manufacturing offers unparalleled freedom. Simple bases save desk space, while sophisticated multi-device workstations organize your ecosystem. Push the boundaries with power arms, closed mechanisms or weight optimization, and work with dedicated rapid prototyping experts to ensure your complex vision becomes a perfect printed reality.

For exhibition stands that require ultimate strength, stability and luxurious finishes, metal 3D printing via SLM technology is the best solution. Companies like GreatLight leverage advanced hardware and deep materials expertise to solve complex prototyping challenges. They provide custom metal parts with precise tolerances, custom materials and integrated finishing, streamlining production while ensuring a robust, high-value charging solution. Ready to redefine your charging habits? Explore the potential of 3D printing, or work with a prototyping expert to create your perfect exhibition stand.

Frequently Asked Questions: 3D Printing Apple Watch Charger Stand Questions and Answers

Question 1: Can I use an FDM printer to print a fully functional Apple Watch charger stand myself?

Answer: Of course! Designs using PLA, PETG or ABS are popular. PETG is generally recommended due to its better durability and temperature resistance compared to PLA. Make sure the design allows for Magsafe disc placement to align and provide stable support.

Q2: Are metal 3D printed stents significantly better than plastic stents?

A: Yes, especially for complex or high-contact applications:

- Durability: Metal stands can withstand drops and scratches better.

- Stablize: The inherent weight prevents tipping over, which is crucial for multi-device stands.

- Aesthetics and feel: Metal brings a premium, luxurious look and feel.

- Heat resistance: Extended life with continuous charging cycles.

- strength: Thinner, stronger and more complex designs not possible in plastics can be achieved.

Question 3: Is the 3D printed stand safe for my Apple Watch?

A: If designed correctly, yes. make sure:

- The charging tray is securely fastened.

- The strap is not pinched or stretched.

- The materials used, especially the resin, are stable and non-reactive. In addition to ensuring there are no sharp edges, metal poses minimal risk.

Question 4: How to integrate the MagSafe charging cable?

A: Most designs include specially molded slots, channels, or clips to hold the disc securely while allowing cables to pass neatly through. Professional design prioritizes precise fit and cable routing.

Q5: Is it too expensive to customize a metal 3D printing booth?

A: Metal printing is inherently more expensive than plastic printing due to the materials and complex processes. However, for unique heirloom-quality pieces, custom corporate branding, or complex functional prototypes requiring maximum strength, the investment can deliver tremendous value. Suppliers like GreatLight have optimized processes to offer competitive pricing for custom metal prototypes and low-volume production. Durability often offsets the cost over time.

Q6: What metal material is most suitable for charging stand?

Answer: Common choices:

- Aluminum alloy (e.g. AlSi10Mg): Excellent strength to weight ratio, good corrosion resistance, relatively cost effective for metal printing, easy to finish beautifully (polished, anodized).

- Stainless steel (e.g. 316L): Superior corrosion resistance, high strength, heavier than aluminum.

- Titanium alloy: Highest strength to weight ratio, excellent biocompatibility/corrosion resistance, but highest cost.

Q7: Where can I get custom metal brackets?

A: Rapid prototyping companies specializing in metal additive manufacturing, such as huge lightis an ideal partner. They offer:

- Print design consulting and optimization.

- Advanced SLM printing technology.

- Expertise in material selection and post-processing (smoothing, heat treatment, finishing).

- Precision machining solutions for key interfaces of charging pads.