Rise of Craftsmanship: Create Your Own 3D Printed Articulated Godzilla Statue

Godzilla has been a pop culture icon for decades, inspiring awe and imagination. Today, technology allows fans to bring the King of Monsters to life in unique and personal ways: 3D printed articulated doll. Unlike the physical model, Articulated Godzilla has movable joints at his knees, elbows, tail and even his jaw, allowing him to be dynamically posed for display or play. This sophisticated fusion of art, engineering, and manufacturing represents the cutting edge of accessible customization. However, achieving beautiful, functional articulation requires precision beyond that of a hobbyist’s desktop printer—and this is where professional rapid prototyping really shines.

The complexity behind articulation: more than just printing plastic

Creating an articulated figure that moves smoothly and is durable requires overcoming significant challenges:

- Joint design accuracy: Hinges, ball and socket or pin joints require extremely tight tolerances. Too loose and your limbs will be weak; too tight and they won’t move at all or will wear out quickly. This requires expert CAD (Computer Aided Design) work.

- Structural integrity: The thin joint sections that connect larger objects, such as bulky thighs and calves, are high-stress areas that are prone to breakage if the print quality is poor or the material direction is weak. Strength analysis is critical during the design process.

- Surface Finish and Clearance: Burrs, rough layer lines, or inconsistent printing can prevent parts from fitting together smoothly or cause friction that wears out joints. Post-processing is crucial.

- Material selection: Long service life (wear resistance), layer bond strength and appropriate flexibility when required under movement stress are required.

Desktop FDM printers often encounter these complex problems. Layer lines affect fit, achieving the necessary +/-0.05mm tolerances is difficult, small joint assemblies increase print failures, and accessible materials such as PLA or standard PETG lack the maximum durability required for long-term articulation.

Why professional rapid prototyping is the key to stunning functional results

Taking the 3D printed articulated Godzilla from concept to reality required capabilities far beyond desktop printing. Work with experienced rapid prototyping manufacturers such as huge light Change the result:

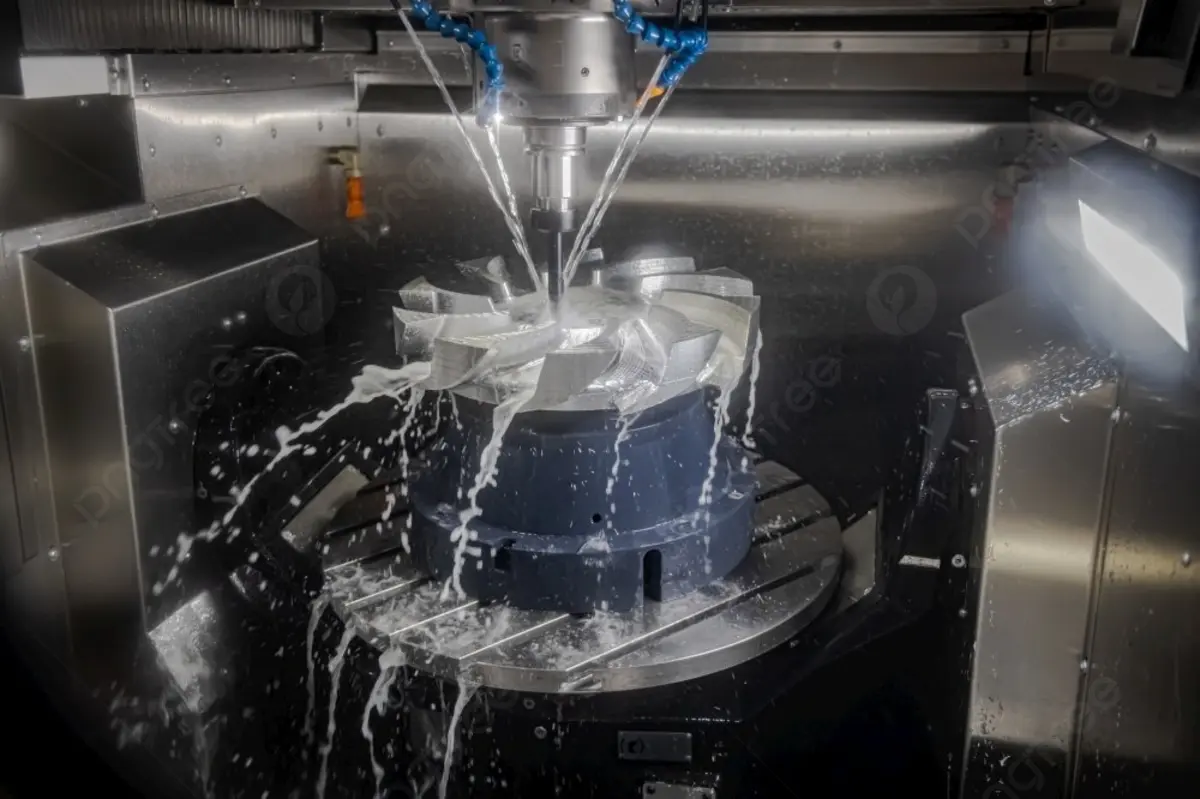

- Industrial grade precision: GreatLight uses advanced Selective Laser Melting (SLM) Metal 3D printers as well as state-of-the-art polymer systems (such as SLS, MJF, SLA). In particular, SLM technology exceeds FDM tolerance capabilities to achieve characteristics as low as ±0.02 mm, which is critical for a perfect fit in mechanical joints. Motion simulation ensures designs function before printing.

- Material mastery: Having access to engineering-grade materials makes all the difference. Metal prototyping (stainless steel, titanium) Provides unparalleled strength and longevity to joints and structural core. For all-polymer figures, Industrial nylon blends (PA11/12), TPU (flexible joints) and specialty resins Providing excellent detail, impact resistance, abrasion resistance and controlled flexibility – far beyond amateur filament.

- Engineering expertise: GreatLight’s team collaborates on design optimization. They proactively analyze models to identify potential weaknesses around joints and recommend modifications, whether it’s strengthening thin joints or adjusting gap tolerances based on the properties of the chosen material.

- End-to-end post-processing: This is where the power is truly unleashed. Parts are precision finished:

- Sanding and Smoothing: Manual and automatic technology ensures perfectly smooth mating surfaces.

- High-precision support removal: Remove supports without damaging fragile joint interfaces.

- Precision reaming and dowel installation: Make sure the nails spin/bind freely.

- Heat treatment (metal): Enhances toughness and durability.

- Vapor Smoothing (Polymer): Creates a glass-like surface and minimizes friction.

- Painting and coating: A protective and beautiful finish that achieves a screen-accurate look, including a wash of proportional detail.

- Customize and iterate quickly: Need a stronger hinge? A longer tail and more points of articulation? An amplified monster? GreatLight handles custom materials, sizes, modifications and rapid design iterations to get every joint movement perfect quickly.

This professional process ensures your Articulated Godzilla isn’t just a model, but a durable, poseable work of art.

Beyond Godzilla: Unleash creativity with professional prototyping

While Godzilla is intriguing, the principles of pronunciation apply broadly. Think custom poseable anime characters, complex biomechanical creatures, rugged poseable dinosaur replicas, or functional engineering models that require precise movement – professional prototyping can unleash limitless creativity. The sophistication displayed by the complex articulated graphics highlights the true depth of the manufacturer’s capabilities.

in conclusion

Creating a 3D printed articulated Godzilla model is more than just additive manufacturing; it’s a complex combination of design, materials science, precision engineering, and meticulous machining. While passion fueled the idea, achieving seamless movement, visual gorgeousness, and long-lasting functionality depended on using professional rapid prototyping services. GreatLight uniquely achieves this through cutting-edge metal/polymer SLM capabilities, unparalleled engineering-grade materials and exhaustive post-processing expertise, turning digital dreams into spectacular, poseable realities. Break free from tabletop constraints and create articulated figures worthy of the monster throne.

Customize your precision-articulated masterpiece with GreatLight today.

Frequently Asked Questions About 3D Printing Articulated Godzilla Figures and Rapid Prototyping

-

Can I really print an articulated Godzilla model?

- Absolutely! By providing well-designed articulated model files (usually .STL), manufacturers like GreatLight can handle the rest – from initial design consultation to prototyping, post-processing and assembly guidance or service.

-

Why choose metal printing (like SLM) to create parts for articulated figures?

- SLM printing of metals such as stainless steel or titanium offers superior strength, wear resistance and longevity, making them ideal for high-stress joint components or internal bones that support moving limbs. This ensures decades of smooth movement without degradation compared to plastic alone.

-

What file format does the manufacturer require?

- STL files are the standard for defining 3D geometry. High-end manufacturers such as GreatLight also accept STEP files for collaborative design analysis and repair before printing to ensure the joint mechanism is functioning properly.

-

How durable are hinged joints compared to injection molding?

- While optimized injection molding provides consistency, modern industrial 3D printing materials and expert finishing allow for comparable durability of the articulated joint. Precision SLM metal printing often exceeds the joint strength of typical plastic toys. Properly machined industrial polymers coupled with expert tolerances ensure a strong hinge.

-

How to achieve such smooth movement of joints?

- Precision printing ensures accurate initial shape tolerances. Sophisticated post-processing is key: careful deburring, high tolerance reaming, aligning critical joint diameters, precise installation of pins/pivots, eliminating looseness/binding, reducing friction, handling flow motion.

-

Can GreatLight help with design or just printing?

- GreatLight provides comprehensive design for manufacturability support. Their engineers evaluate documents, proactively optimize articulation structures, joint clearances, material selection, reduce risk, maximize functional durability, and improvise to effectively change feasibility realities.

-

Does it include post-processing?

- Yes! Services often go well beyond printing, core unit manufacturing, complete assembly, ready parts, smooth friction-reducing joint mating surfaces, optional paint details, and other necessary features. Aesthetics The same process greatly simplifies production.

- What is the typical turnaround time?

- Turnaround time depends on model complexity Materials Level of completion required Typically ranges from days to weeks Iteration prototypes Final production Heroes Discuss upfront delivery schedule Adjust project needs GreatLight Prioritizes speed Accuracy Flexibility Complex custom orders.