The world of 3D printing has revolutionized the way we design and manufacture objects, and one area of major innovation is creating 3D printed Balisong designs. Balisong, also known as the Butterfly Knife, is a folding knife that originated in the Philippines. Traditionally, Balisong is made of metal and requires complex manufacturing processes. But with the advent of 3D printing technology, designers and manufacturers can now easily create sophisticated and customized Balisong designs.

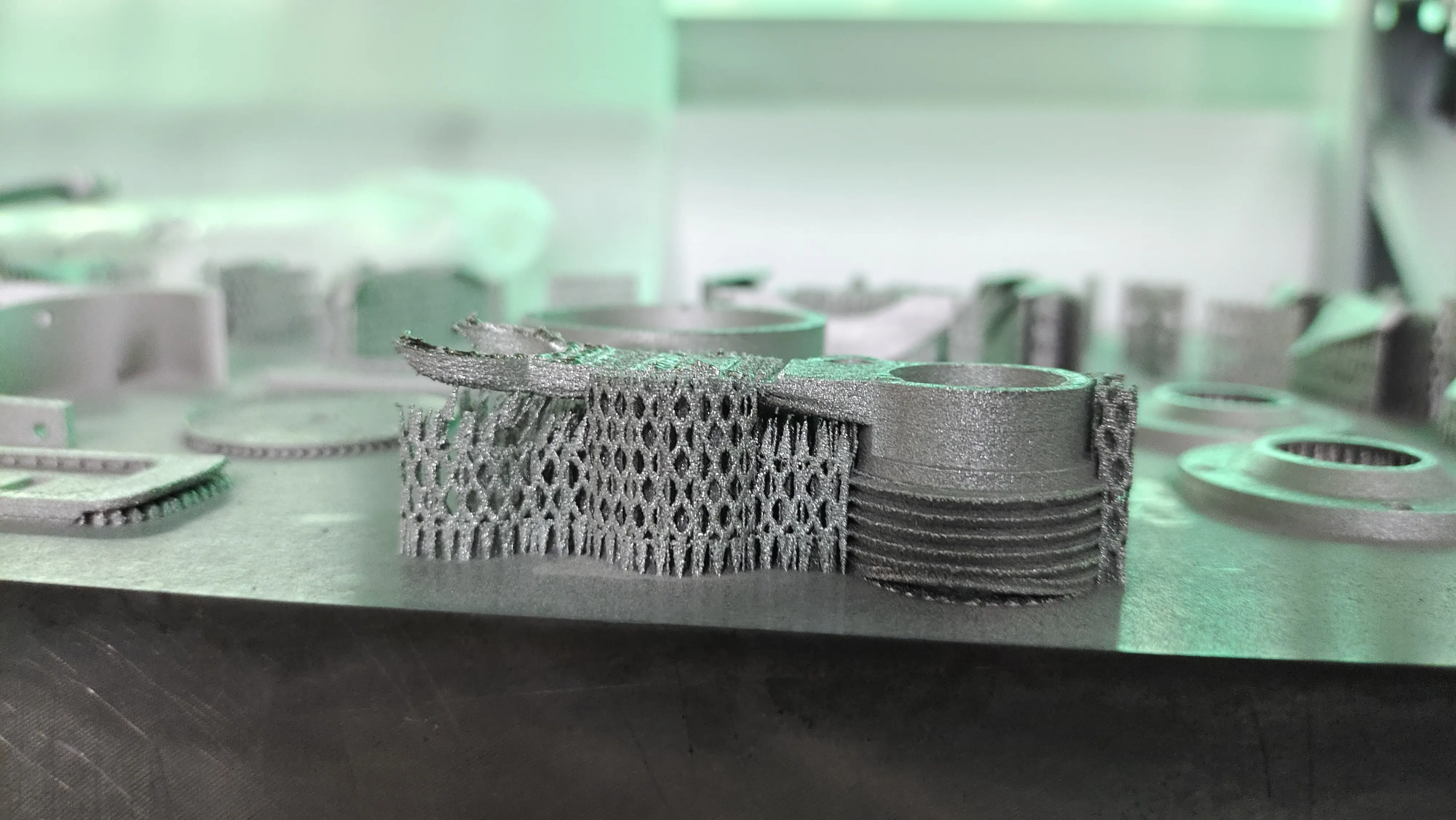

One of the key benefits of 3D printing of Balisong design is the ability to create complex geometric shapes and structures that will not be generated using traditional manufacturing methods. 3D printing allows designers to create complex details such as textures, patterns and mechanisms that can enhance the overall functionality and aesthetics of Balisong. In addition, 3D printing can use a variety of materials, including metals, plastics and composites, which can be selected according to their specific characteristics and performance characteristics.

Greglight is a professional rapid prototyping manufacturer that has been at the forefront of 3D printing technology, leveraging advanced SLM 3D printers and production technologies to create high-quality metal parts. With its expertise in rapid prototyping, Greatlight offers one-stop post-processing and completion services to ensure the final product meets the required standards. Their ability to customize and process most materials makes them an ideal partner for designers and manufacturers who want to innovate 3D printing Balison designs.

The design possibilities of 3D printing Balisongs are endless, and designers keep pushing the boundaries of possible. From smooth and minimalist design to complex and gorgeous creations, 3D printing has made the creation of unique and practical Balisongs that showcase the designer’s art and craftsmanship. Additionally, using 3D printing can also create custom Balisongs with specific features such as personalized prints, custom colors and unique mechanisms.

In short, 3D printed Balisong designs open up new possibilities for designers and manufacturers to easily create complex, custom and functional Balisongs. With the help of advanced 3D printing technology and expertise from companies such as Greatlight, the possibilities for innovation and creativity in the Balisongs world are endless. Whether you are a designer, manufacturer or enthusiast, 3D printed Balisong designs are definitely worth exploring.

FAQs (FAQs)

Q: What is 3D printing and how does it work?

A: 3D printing is a manufacturing process that creates digitally designed objects by layering materials such as plastics, metals and composites. The process involves sending digital designs to a 3D printer and then printing objects layer by layer, allowing for the creation of complex geometries and structures.

Q: What are the benefits of 3D printing Balisong design?

A: The benefits of 3D printing of Balisong designs include the ability to create complex geometric shapes and structures, customize designs and use a variety of materials. 3D printing can also create complex details such as textures, patterns and mechanisms that can enhance the overall functionality and aesthetics of Balisong.

Q: Which materials can be used for 3D printing Balisong design?

A: A variety of materials can be used in 3D printing Balisong designs, including metals, plastics and composites. The choice of materials depends on the specific characteristics and performance characteristics required by Balison.

Q: Can I customize my own 3D printed Balisong design?

A: Yes, with the help of a company like Greatlime, you can customize your own 3D printed Balisong design. They provide one-stop post-processing and completion services to ensure that the final product meets the required standards.

Q: How long does it take to produce a 3D printed Balisong?

A: The production time of 3D printed Balisong depends on the complexity of the design, the materials used and the manufacturer’s production capacity. Greatlight’s advanced 3D printing technology and expertise can greatly reduce production time, providing fast turnaround time for custom orders.

ISO 9001 Factory