Revolutionary Movement: 3D Printing of Ball Joint Power

Ball joints are basic mechanical components that act as flexible pivot points to achieve smooth multi-directional motion in countless applications. From car suspension systems and robotic arms to aviation mechanisms and medical devices, they are all unsung heroes with freedom of rotation. Traditionally, manufacturing these complex spherical components involves expensive multi-step processes such as casting, forging and extensive CNC machining – often requiring laborious post-assembly work as well as facing design limitations. Enter 3D printinga groundbreaking technology that changes how we conceive and create ball joints, providing unprecedented flexibility, speed and performance.

Why 3D printing is the game changer of ball joints:

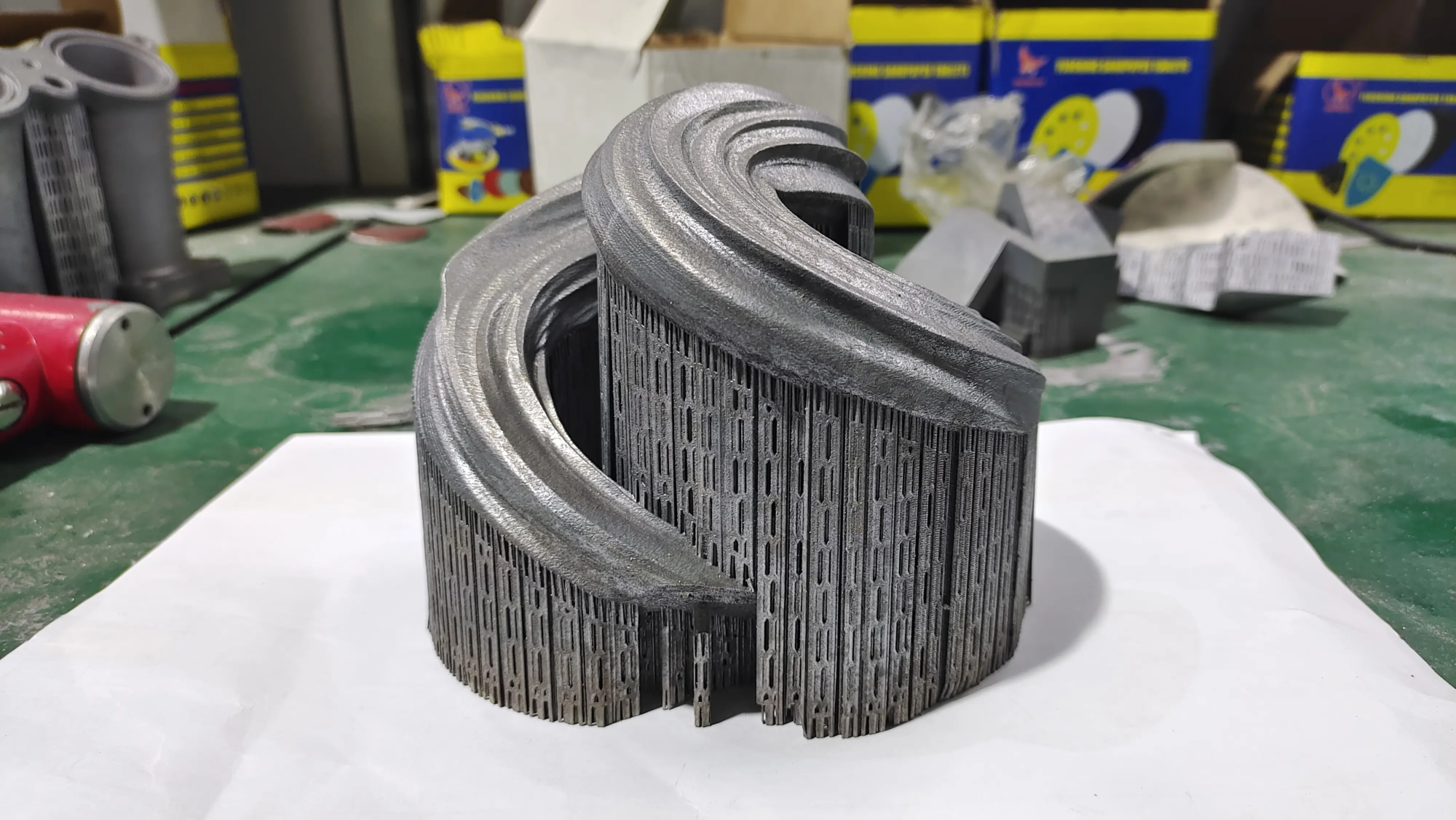

- Design freedom and complexity: 3D printing frees designers from traditional constraints. Complex internal channels for lubrication, integrated lightweight lattice structure or customized geometry tailored to specific load paths and metrics of freedom. Imagine a ball joint with an internal fluid channel that is continuously lubricated – can be achieved by additive manufacturing (AM), but it is very difficult or impossible to use conventional methods.

- Rapid prototype and iteration: Develop new ball joint design? 3D printing has accelerated the cycle dramatically. Functional prototypes can be produced in hours or days instead of weeks or months, allowing engineers to quickly test form, fit, function, and performance. Fail quickly, learn faster and perfect the design with minimal delay.

- Lightweight without sacrificing power: Technologies such as topology optimization go hand in hand with 3D printing. Software algorithms minimize material use only where performance is critical, creating complex, lightweight lattice structures within joints. Combining strong, lightweight metal alloys such as titanium or aluminum alloys allows for substantial weight savings – critical for aerospace, robotics and automotive efficiency.

- Parts merge: Traditional ball joint components usually require multiple separate parts (ball studs, sockets, housings, seals). 3D printing can combine them into one integrated unit, and can greatly reduce the number of components. This simplifies the assembly, eliminates potential points of failure (such as loose bolts), and improves overall reliability and seal potential.

- Custom and on-demand manufacturing: Need a highly professional ball joint for unique robotic limbs or custom vehicle applications? AM is economically feasible and efficient in small batches or one-time production. Even custom wear patterns or surface treatments for specific friction profiles are possible.

- Performance Materials: Modern metal 3D printers, especially Selective laser melting (SLM)using high-performance alloys:

- Stainless steel (e.g., 316L, 17-4 pH): Excellent corrosion resistance, good strength, widely used.

- Titanium alloys (for example, Ti-6al-4V): Excellent strength to weight ratio, biocompatibility (excellent medically), corrosion resistance.

- Aluminum alloy (e.g., Alsi10mg): Lightweight, good thermal properties, perfect for weightlifting applications.

- Mali Steel: Super high strength, for demanding structural applications.

- Nickel alloys (for example, inconel): For extreme environments (high temperature, corrosion). Options for functional polymers (such as PEEK) also have less demanding non-metallic applications.

SLM: Gold standard for metal ball joints:

Selective laser melting (SLM) is especially suitable for producing robust high-precision metal ball joints. This powder bed fusion technology uses a powerful laser to melt layer by layer and fuse fine metal powder particles. SLM Delivery:

- High density and strength: The production of parts close to the theoretical material density is crucial to structural integrity.

- Outstanding feature resolution: Enables the creation of details within the socket and ball surface.

- High-quality surface finish potential: Although bearing surfaces may require post-treatment, the starting point is usually better than casting.

- Material integrity: Achieve mechanical properties that are comparable to those that sometimes exceed forged materials.

Precautions for designing 3D printed ball joints:

- Support structure: Dangling functions, such as ball studs, inevitably need to be supported during printing. Careful orientation and support design are essential to minimize post-treatment labor and maintain surface quality of critical bearing surfaces. Advanced simulation tools can predict support requirements and potential distortions.

- Clear and tolerate: Achieving the exact dimensional accuracy and consistent gap between the ball socket is critical for optimal performance and life. The inherent accuracy of SLM is helpful, but factors such as heat shrinkage must be considered during the design stage. Post-processing (e.g., precision machining, honing, packaging) is often crucial to implementing the final tolerance of the functional surface.

- Surface finish: The printed surfaces now (especially rough ones) may not be ideal for bearing functions. Specific post-treatment techniques may be required, such as polishing, grinding or completing inserts with inserts to achieve low friction and wear characteristics. Consider integrating smooth surfaces into the design where possible.

- Concentrated pressure: The sharp corners are the pressure concentrators. A thorough FEA (finite element analysis) combines topological optimization with generous rounded corners in high stress areas to ensure structural integrity under load.

Industry applications soar with 3D printed ball joints:

- Cars and Motorsports: Suspension assembly, steering connection (lighter weight, optimized performance), custom small batch vehicles.

- Aerospace and Defense: Landing gear assembly, flight control surface, actuation system (weight reduction), custom drone/drone mechanism.

- Robotics: Robot joints, manipulators, exoskeletons – Through custom design, greater freedom of movement and precise accuracy can be achieved.

- Medical equipment: Prosthetics, surgical robotics, require professional equipment with biocompatible materials and customized geometry.

- Industrial Machinery: Actuators, articulated arms, material handling systems require robust, custom-made wear parts.

Why collaborate with Greatlime for your 3D printed ball joint?

exist Greatwe are in Rapid prototyping and metal additive manufacturing solutions. We don’t just print parts; we solve the composite Problems with rapid production of metal parts Have innovation and expertise. Here is how we empower you with the project:

- Advanced SLM Technology Center: We invest in state-of-the-art SLM 3D Printerensure access to the most capable metal AM systems for demanding applications such as high-performance ball joints.

- Deep material expertise: Our playgrounds are a variety of metals (and polymers). We guide you in material selection for optimal strength, weight, corrosion resistance and functional requirements.

- Engineering Design Partnership: Our team works with your engineers to consider the design of additive manufacturing (DFAM) principles from the very beginning. We optimize ball joint geometry for printability, performance, weight and cost.

- Comprehensive post-processing: We provide real One-stop post-processing and completion service. From removal of critical support structures and precise machining/grinding of bearing surfaces to heat treatment (relieving pressure, aging, hips), surface treatments (shooting, polishing, polishing) and coatings – we make sure your ball joints perform well and are ready.

- Speed and flexibility: Quick customization and processing. From fast functional prototypes to low-volume production runs, we encountered positive schedules without compromising quality.

- Custom Precision Expert: As One of the best rapid prototyping companies from Chinawe specialize in research Custom precision machining Integrate into our AM workflow to ensure dimensional accuracy of ball joint requirements. We produce parts as strict specifications.

Don’t let regular manufacturing limitations limit your next innovation. Customize your precision fast prototyping parts now at the best prices! [Link to GreatLight Contact/Quote Page]

in conclusion

3D printing, especially advanced technologies such as SLM, fundamentally disrupts the design and manufacturing of ball joints. It goes beyond traditional limitations, unlocks previously impossible geometry, achieves unprecedented lightness, accelerates development cycles and facilitates true customization. While challenges such as support generation, precise cleaning and critical surface finishes require thoughtful design and expert post-processing, the advantages far outweigh them. Platforms such as Greatlight, equipped with cutting-edge SLM technology and comprehensive engineering and finishing capabilities, enable the industry to leverage the full potential of 3D printed ball joints – driving mobility, automation, and innovation in other regions. Future pivot points are printed.

FAQ: 3D printed ball joints

-

Are 3D printed ball joints as strong as traditionally made ball joints?

- Tensile and yield strengths are produced when high-quality metal SLM printing using appropriate materials such as Ti-6al-4V or Maraging Steel and appropriate process parameters The material itself Can satisfy or exceed cast or forged equivalents. The key is expert design (avoiding stress concentrations), controlled printing and usually subsequent heat treatment. this Overall joint strength It also depends on the design optimization and after-treatment of the bearing surface.

-

What are the main limitations of 3D printed ball joints?

- Surface finish: The surface of the meter usually requires functional bearing applications.

- tolerance: Accuracy tolerances for hardening on key ball/socket interfaces usually require post-arrangement/grinding.

- Support structure: Their removal increases time/cost and may affect surface quality.

- Dimension constraints: The printing mechanism construction limits the maximum size of a single print connector.

- Large cost: While the cost-effectiveness of prototypes/complex parts/low volumes, in some cases, high-volume production may still be beneficial for casting/forging.

-

What kind of post-treatment is usually required for metal 3D printed ball joints?

- Basic: Supports removal, stress relief heat treatment.

- Functionality is crucial: Precision machining (CNC milling/turning), grinding, grinding or harvesting of ball and socket bearing surfaces to achieve the desired surface finish (RA, RZ) and dimensional tolerance.

- Common: Other heat treatments (solution treatment, aging, porosity reduction hip joints), surface treatments (shooting, polishing, polishing, paints, such as DLC-diamond-like carbon), cleaning.

-

Can 3D printed ball joints withstand high loads and pressures?

- Yes, as long as they are correctly designed using topological optimization and FEA, i.e., printed from suitable high-strength alloys using optimized SLM parameters and subjected to appropriate heat treatment. Post-treatment to ensure proper surface contact and to eliminate stress concentrators is crucial.

-

How much does 3D printing ball joints compare to traditional methods?

- for Prototype and low to medium volume3D printing can be highly cost-effective by eliminating expensive tools (molds, deaths) and enabling parts mergers. Reducing assembly time is also a factor.

- for Simple design produced in very high volumeDue to economies of scale, traditional methods (casting, forging) usually have lower costs per unit of parts.

- The greatest value is usually Performance improvement (lightweight, efficient) and Time to accelerate to the market Enabled by AM.

-

Does 3D printed ball joints require lubrication?

- Yes. Like any ball joint, lubrication also reduces friction and wear. The important advantage of AM is the potential of design Comprehensive lubrication channel Direct access to the joint housing for easy maintenance and even continuous lubrication systems that are difficult to implement in traditionally assembled joints.

- Why choose an expert like Greatlight, why not just any 3D printing service?

- Producing truly functional, reliable ball joints requires deep expertise rather than simply operating the printer. It includes DFAM Consulting Companystrict Material and process knowledgeadvanced Post-processing function (especially for precise processing of bearing surfaces), Quality control For key dimensions and Functional requirements. Greglight’s attention Professional rapid prototyping of metal parts Provide this comprehensive expertise.