The dawn of energy innovation: Are 3D printed batteries the future?

Imagine a battery that fits perfectly into your smart watch, an electric car battery with a maze of cooling channels for unprecedented efficiency, or an implantable medical device with a built-in power source that matches the biological structure. This is not science fiction, but the prospect of 3D-printed batteries, a revolutionary approach that will redefine energy storage as we know it. At GreatLight, we explore how additive manufacturing can move beyond metal part prototyping to drive breakthroughs in electrochemical devices.

Why use 3D printed batteries?

Traditional battery manufacturing relies on stacked layers of fixed-shape electrodes and separators, limiting design flexibility. 3D printing breaks these limitations by enabling complex custom architectures. Manufacturers build cells layer by layer using techniques such as extrusion printing (for paste electrode materials), inkjet printing (for nanoparticles) or laser-assisted processes. This allows:

- Ultra-precision electrode engineering: Complex geometry increases surface area to volume ratio, accelerating ion diffusion for faster charging.

- Multi-material integration: Simultaneous printing of anodes, cathodes, electrolytes and conductive supports simplifies production.

- Apply optimized shapes: The battery becomes an integral part of the device rather than an add-on, ideal for aerospace, medical implants and IoT sensors.

Materials Innovation: Beyond Traditional Chemistry

While lithium-ion dominates today’s market, 3D printing unlocks new materials that are incompatible with traditional processes. The researchers experimented with graphene aerogels for ultralight cathodes, solid electrolytes for inherent safety, and sodium ion mixtures for sustainability. Each layer can be tuned for porosity, conductivity or flexibility, paving the way for batteries to deform with clothing or resist satellite gravity.

Advantages Beyond Shape: Performance and Sustainability

- higher energy density: Micro-lattice electrode design improves the utilization of active materials.

- rapid prototyping: Developers can accelerate R&D breakthroughs by iterating on electrochemical designs in days instead of months.

- reduce waste: Only necessary materials are deposited, reducing excess material and enabling eco-efficient circuits.

- Thermal management: Printed cooling channels or phase change materials enhance the safety of high-density packaging.

GreatLight’s role in accelerating adoption

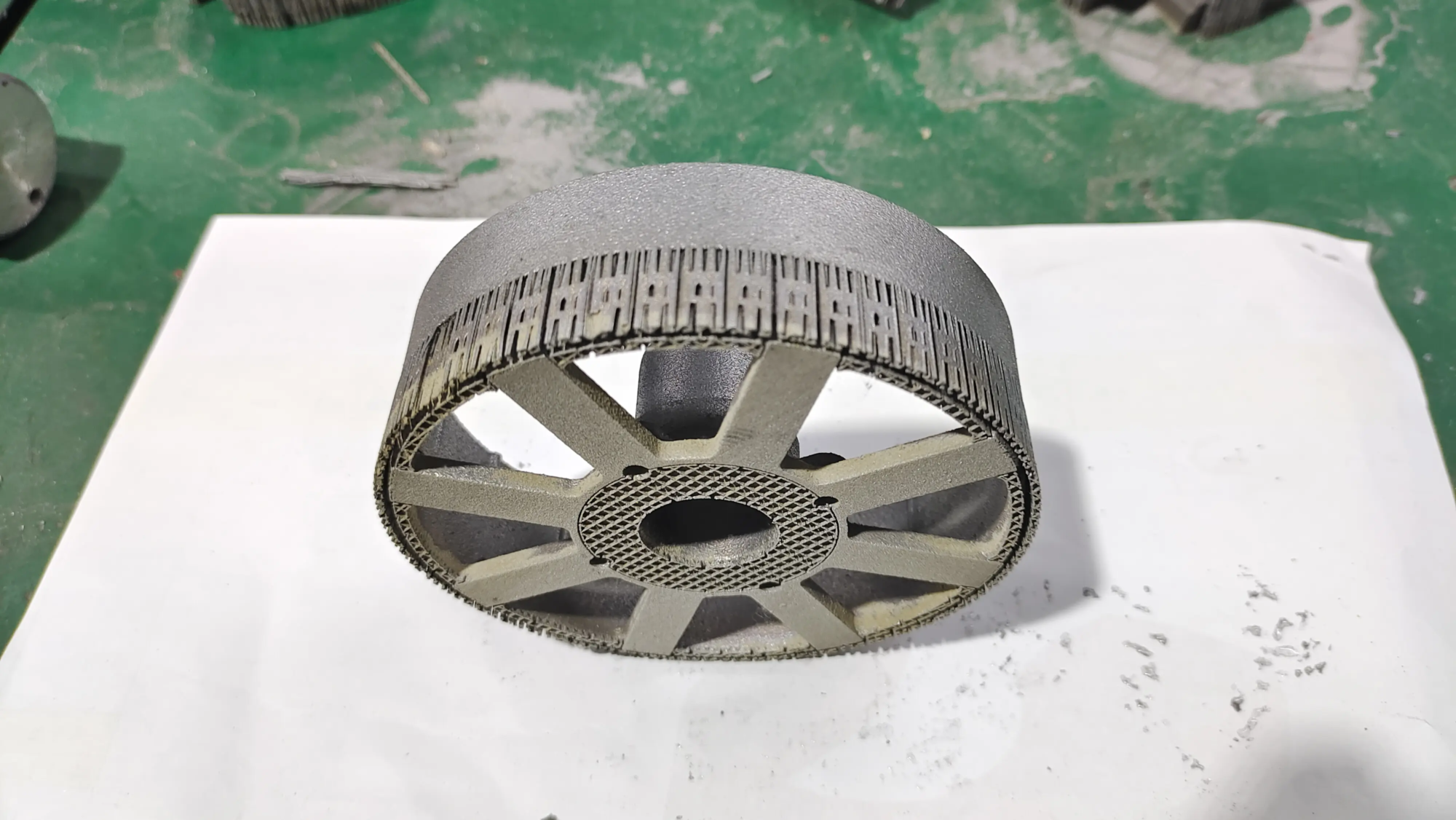

At GreatLight, SLM (selective laser melting) 3D printing expertise allows us to create intricate details Metal casing and conductive frame for next-generation batteries. While traditional batteries rely on polymers and composites, emerging hybrid systems utilize metallic components for thermal stability and mechanical support. Our advantages are:

- Precision metal manufacturing: Create nanoscale current collectors optimized by SLM.

- Rapid prototyping expertise: Helping startups and researchers validate novel battery designs in record time.

- Post-processing integration: Apply coating to prevent corrosion and improve electrolyte adhesion.

Scaling challenges

Despite early success, obstacles remain:

- Material limitations: Printable mixtures must balance viscosity, curing properties, and electrochemical efficacy.

- Scalability: Lab-scale printers struggle to cope with high-volume manufacturing, and advances in nozzle arrays and AI-driven calibration aim to bridge the gap.

- cost: Nano-formulated electrode inks increase material costs and require economies of scale.

- standardization: Unified security protocols lag behind technological advances.

Real-world applications are taking shape

- medical device: Printed biocompatible batteries in Knee replacement or hearing aids.

- electric car: Weight-optimized battery pack with integrated cooling.

- space exploration:Lightweight power unit resists extreme vibration.

future outlook

3D printed batteries are transitioning from academic labs to pilot production lines. By 2035, we expect niche markets such as wearable technology to see commercial adoption. Success depends on collaboration between materials scientists, printer manufacturers and energy experts. Governments are also supporting a variety of initiatives—from EU green energy plans to U.S. Department of Energy grants—making this innovation unstoppable.

Conclusion: Powering tomorrow today

3D printed batteries symbolize the future of "power pack" arrive "Power architecture." They promise to create unique energy storage that is safer and more efficient for our evolving world. While challenges remain, advances in printable materials and scalable printing systems will solidify their role in an electrified future. At GreatLight, we are proud to contribute our rapid prototyping capabilities to drive this transformation – one precise layer at a time.

FAQ

Q1: Can 3D printed batteries be used commercially?

It has not been applied on a large scale yet. Prototypes power small devices, but automotive-grade deployment will take 5 to 10 years. Major players such as Sakuu and Blackstone have invested heavily in pilot facilities.

Q2: Can the performance of 3D printed batteries be better than traditional batteries?

potentially Yes. Customized electrode shapes can increase energy density by 20% due to efficient ion transport paths. However, cycle life verification is still ongoing.

Q3: What materials are used?

Injection Versatility: Metal oxides like LiFePO₄, graphene nanowires, polymer electrolytes and specialty alloys designed for SLM printing.

Q4: Why do batteries need metal printing?

Metal additive manufacturing ensures a strong mechanical frame and complex support lattice, which is critical to the battery’s longevity under vibration/stress. It also supports embedded conductive paths in electronic devices.

Q5: Is this technology environmentally friendly?

Yes – minimal material waste is in line with the circular economy. Recyclability depends on the printable chemistry, but is easier to disassemble than resin-sealed rectangular cells.

Q6: How does Honglaite support this innovation?

We specialize in ultra-precision metal prototyping and finishing of compact components. With primary SLM equipment, we accelerate iterative testing of electrodes, connectors and structural elements.

Customize your next energy storage prototype with GreatLight—precision solutions engineered for future breakthroughs.