The Evolution of the Bookshelf: How 3D Printed Bookshelf Ideas Are Redefining Storage

Imagine a bookshelf that grows with your collection, curves around corners like a liquid sculpture, or can be disassembled into your suitcase. This isn’t science fiction – it’s manufacturing, powered by advanced rapid prototyping technology, where form truly follows function. The ubiquitous yet often mundane bookshelf has become fertile ground for 3D printing innovation, allowing designers and homeowners to escape the traditional constraints of mass production. In our space at GreatLight, we recognize the transformative potential of this application.

Why choose 3D printed bookshelf?

Unlike traditional woodworking or metal fabrication, 3D printing builds objects layer by layer based on a digital design. This will unlock:

- Complex geometric shapes: Create organic curves, hollow supports, or interlocking parts that wouldn’t be possible with a saw or press.

- Mass customization: Easily resize, shape or personalize components.

- Material efficiency: Generate lightweight yet strong structures using topology optimization.

- Iterate quickly: Quickly prototype and refine designs without expensive tools.

The following 5 groundbreaking 3D printed bookshelf concepts demonstrate this potential:

1. of "fractal growth" Modular system

- concept: Inspired by crystal or plant structures, the system uses self-similar interlocking units (triangles, hexagons). Start with a module; connect other items horizontally, vertically or diagonally to create infinite configurations – minimalist corner shelves, massive wall units, or even room dividers.

- 3D printing advantages: 3D printing excels at producing the same, complex joint mechanisms consistently. Printing small units minimizes bed size constraints.

- Material Pro Tips: For lightweight parts (shelves), use glass-filled nylon (SLS). For structural connectors subject to heavy loads, SLM printed aluminum offers excellent strength-to-weight ratio and durability – GreatLight’s core expertise.

2. Biomorphology "living roots" wall mount bracket

- concept: Instead of bulky frames, floating shelves are mounted to intricate vine-like or root-like brackets printed directly onto the structural wall brackets. The stand serves a dual purpose: load-bearing support and organic artwork.

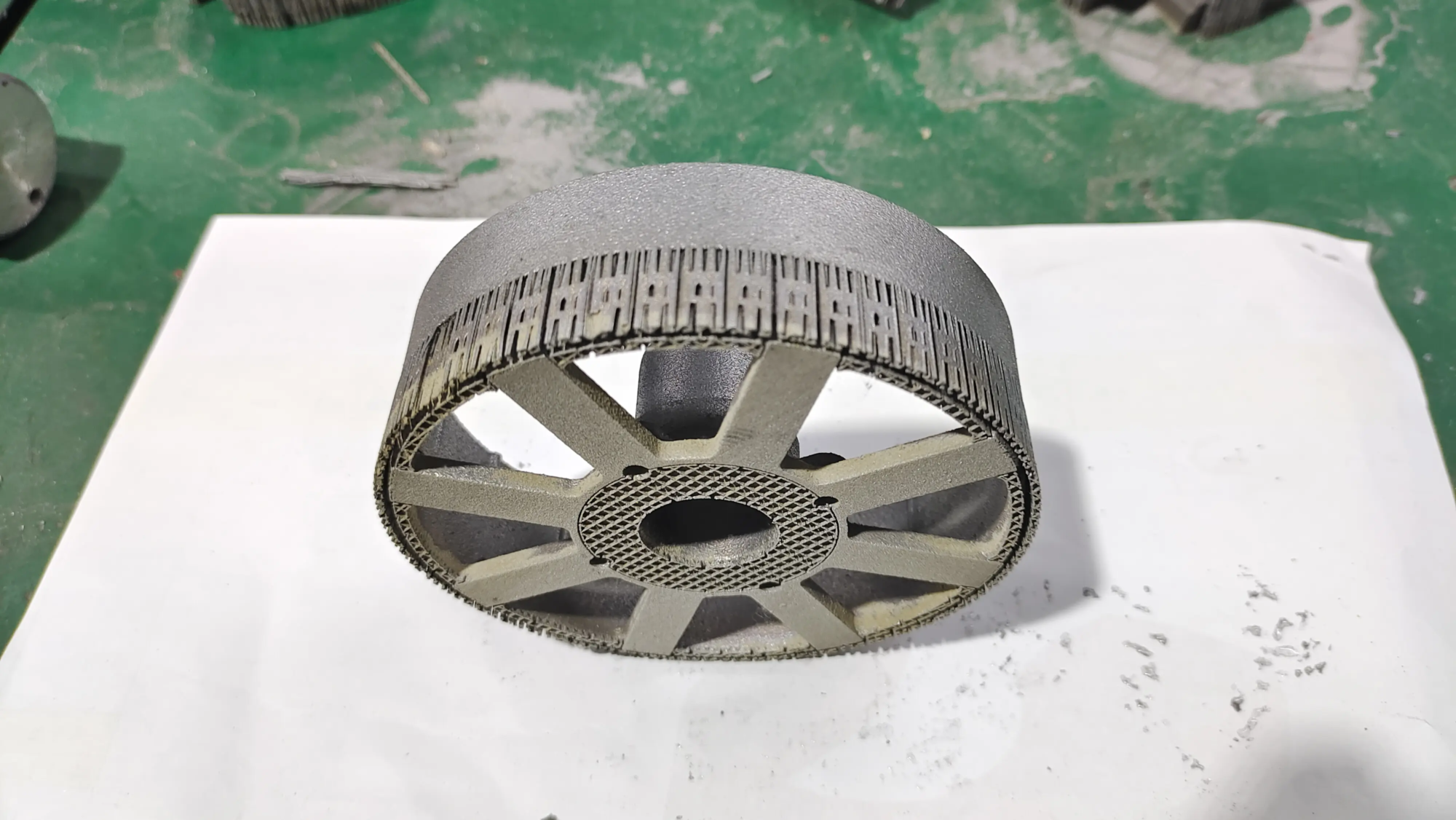

- 3D printing advantages: Achieving a complex internal lattice structure radically reduces weight while maintaining rigidity. Seamlessly integrate mounting hardware into printing.

- Material Pro Tips: Laser metal printing (especially SLM, our expertise at GreatLight) is ideal. Using materials like titanium allows for the extremely fine detail required for an organic aesthetic while providing the superior tensile strength needed to securely hold a bookshelf full of books.

3. Origami Portable Stand

- concept: Ultra-light bookshelf designed for travelers, small spaces, or temporary use. Based on origami principles, it uses custom interlocking hinges to compactly fold flat and unfold into a stable, multi-tiered shelf. Crimp assembly requires no tools.

- 3D printing advantages: The integrated precision hinge and snap mechanism are printed into one piece to ensure a strong and reliable folding action that cannot be achieved by traditional assembly methods.

- Material Pro Tips: Flexible polymers such as TPU enable compliant hinges, while load-bearing panels benefit from SLM printed stainless steel or aluminum For thin-wall rigidity, which is crucial in portable designs, GreatLight typically uses handles. The composite design combines mechanical/frame metal with a printed polymer panel technology setup.

4. Algorithm flow frame

- concept: The shelf uses algorithmic design software to visually represent the flow of data, sound waves or force distribution on its structure. The shelf surface has an undulating shape, is visually thicker where the load is greatest, and may integrate curved mounting elements that appear "flow" Go down the wall.

- 3D printing advantages: Translate computational topology optimization and organically generated designs directly into physical objects. Achieve structural efficiencies not possible with standard manufacturing and minimize material reduction.

- Material Pro Tips: To achieve this it is best to use metal printingas fine control over the internal lattice and complex surface geometry effectively maximizes strength. GreatLight’s SLM printer ensures accuracy Perfectly transform computational models into robust