Unleash your in-house master: The ultimate guide to 3D printing custom chess boards

Chess is more than just a game, it reflects its art, strategy and personality. Why settle for the next universal board when you can create something as unique as the game style? Making custom chess boards becomes an easy-to-access DIY project with 3D printing. Whether you are an amateur or experienced player, this guide will cover design, printing and finishing professional-level boards.

Why 3D printed chess board?

- Endless customization: Integrate family crests, geometric patterns or personalized prints.

- Material versatility: Use an affordable PLA as a home printer, or choose high-quality metals such as high-quality and durability.

- Educational Value:Master CAD design and additive manufacturing principles.

- Cost-efficiency: Avoid retail markings; the filament price of standard plastic sheets is under $20.

For complex designs that require industrial-grade quality (especially metal) Great Ensure perfect results. Their expertise in metal 3D printing (SLM), post-processing and rapid production elevates the DIY concept to a museum-worthy work.

Part 1: Design Phase – Where creativity fits in precision

Software Tools:

- beginner: tinkercad (web-based, intuitive drag and drop).

- Advanced: Fusion 360 (parameter design of interlocking parts).

Key Design Considerations:

- aspect: Standard Square 2–2.5 inches. Consider boundaries (1-2 inches) and height (0.5-1 inches).

- Modular: Design separate tiles for easy printing. Seamless components are made with puzzle-like interlocks.

- support: Overhang > 45° requires support. The sloped tile edges simplify printing.

- Storage: Drawers or nested slots under the integrated board.

For prompts:

Add the hidden engravings (such as your abbreviation) below before printing. This is a subtle signature of your masterpiece.

GRESTILLE ADVATICE:

Professional designers perfect your STL files for manufacturability. They ensure optimal wall thickness, warping resistance and support position – for metals such as titanium or aluminum alloys.

Part 2: Print – From Digital to Physics

Plastic board (DIY method):

- printer: Entry-level FDM printers (for example, Creality Ender 3).

- Material: PETG (durable) or PLA+ (high detailed). Avoid abdominal muscles caused by warping.

- set up:

- Layer height: 0.15 mm smooth surface.

- Fill: 25% (rigid hexagon pattern).

- Bed temperature: 60°C (PLA), 80°C (PETG).

- Time estimation: 20–40 hours (split tiles with 0.2 mm gap).

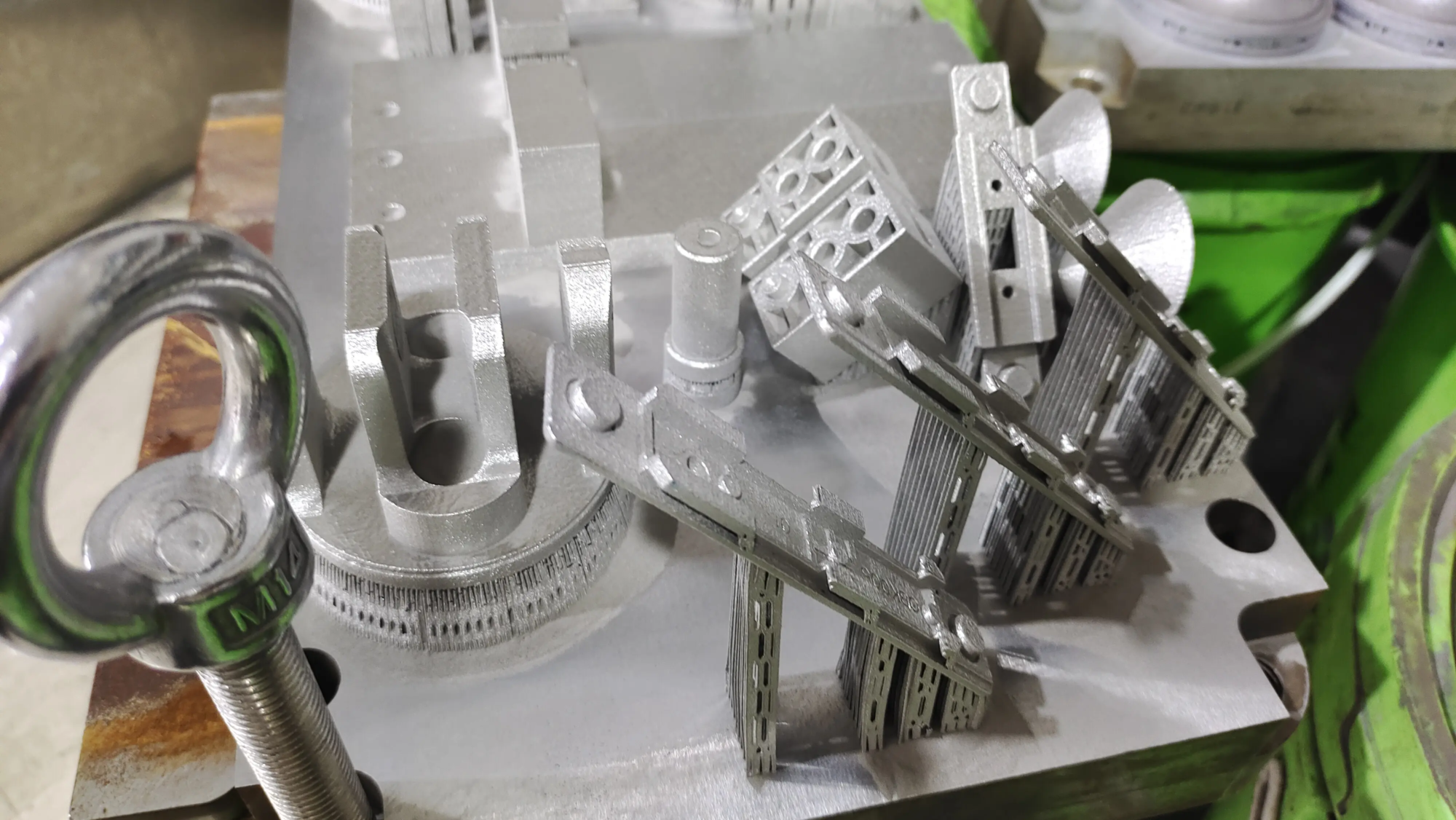

Metal plate (Greglight Specialty):

- technology: Selective laser melting (SLM).

- Material: Stainless steel (budget-friendly), aluminum alloy (lightweight) or titanium (luxury).

- Why outsourcing?:

- The price of SLM printers is $100K+ and require an inert gas environment.

- Greatlight treatment pressure relief heat treatment to prevent cracking.

- Achieve 0.1 mm accuracy and be prepared for polished surface quality.

Part 3: Post-processing – Perfect Art

Plastic finish:

- Support deletion: Clip support, then sand (220→600 grit).

- smooth: Use epoxy or fill primer for layer line hiding.

- dyeing: Spray paint square or spray gun gradient. Sealed with matte varnish.

Metal finish (professional layer):

Greglight’s one-stop post-processing includes:

- Processing: CNC-MILL surface for chessboard flow.

- polishing: Mirror finish or beaded texture.

- coating: anodized (color), PVD board (scratch) or patinas.

- assembly: Laser welded tiles for invisible seams.

example: A stainless steel plate polished onto the mirror finish reflects pieces like glass panes, which is ideal for a luxurious suit.

Conclusion: Make Your Legacy

3D printing transforms chess boards from mass-produced projects to personal statements. While beginners can create impressive plastic panels at home, metal design requires industrial expertise. Great Bridging this gap, providing SLM 3D printing, and matching post-processing of the aviation layer. Their rapid prototype service (from concept to finished product) ensures that your board bears membership for generations.

Are you ready to move from pawn to the king? Upload your design to get a quote Greatwhere precision meets passion.

FAQ: Your Chess Board of Directors Questions, Answers

Q1: What is the most durable material for a 3D printing chessboard?

The metal plate (stainless steel, aluminum) is almost indestructible. PLA lawsuits are used at will; PETG provides intermediate resilience. For longevity, Greatlight’s SLM printed metal includes optional hardening treatment.

Q2: How long does it take to print?

Plastic tiles: 5–8 hours each (for 64 squares). All-metal plates through SLM by careful laser sintering: 24–72 hours. Gremblight reduces delivery time to 5 days with batch processing.

Q3: Can I print the board on a basic FDM printer?

Yes! Use PETG/PLA and design modular tiles. Avoid overhangs > 45° to minimize support. Upgrade to a 0.2mm nozzle for crisp edges.

Q4: Are metal printing boards safe and regularly used?

Absolutely. Greglight’s non-toxic SLM alloys (for example, 316L stainless steel) are food safe after polishing. Unlike plastics, they resist humidity and UV degradation.

Q5: What is the cost range?

Plastic (DIY): $15–$30 (Filament). Metal (Greglight): $100–$600, based on size/material. Complex prints or gold plating increase by 10-20%.

Question 6: Why choose SLM instead of casting of metal plates?

SLM eliminates the mold, thus making complex geometries (e.g., hollow storage chambers) impossible to cast. Customized works at one time are also faster.

Question 7: How to maintain metal chess boards?

Wipe with a microfiber cloth. Avoid acidic cleaners. Regular repolishing (or Greatlight’s PVD coating) prevents oxidation with minimal effort.

Are there any more questions? [Contact GreatLight’s engineering team]- We weirdly make your eyesight playable.