When Myths Fly: The Art of 3D Printing Chinese Dragons and Pushing the Boundaries of Imagination

Few creatures capture the imagination like the Chinese dragon. Unlike the fire-breathing snakes of the West, this celestial serpent symbolizes wisdom, strength, prosperity and natural vitality. Its sinuous body, decorated with intricate scales, claws, beards, and often clutching a mysterious pearl, is a masterpiece of mythological design. Historically, the dragon’s complex form has posed great challenges to craftsmen. Today, advanced 3D printing technologies, specifically metal additive manufacturing, offer a revolutionary way to bring this legendary symbol into the tangible world with unprecedented detail and material possibilities.

Legacy of the Dragon: More than a Myth

Before delving into this technique, it is crucial to understand the importance of dragons. In Chinese culture, the dragon (龙 – Lóng) is a revered spiritual entity associated with the emperor, water, rainfall, and cosmic yang energy. It is a benevolent force that symbolizes strength, good fortune and transformation. Its physical description is well thought out:

- Meandering form: Represents flexibility and adaptability.

- scales: Provides protection and resilience.

- paw: Symbolizes power and authority.

- pearl: Often with a flame pearl symbolizing wisdom, truth, enlightenment or the moon.

Creating a physical representation worthy of this symbolism requires capturing not just the form, but the spirit embodied in every curve and intricate detail—a task well suited to modern manufacturing capabilities.

From CAD to Creation: Conquer Complexity with 3D Printing

Designing a 3D printable Chinese dragon is no easy task. Its flowing, organic geometry and tiny surface details, such as overlapping scales or fine whiskers, can overwhelm traditional CNC milling or casting methods. This is where additive manufacturing shines:

- Digital engraving: The artist uses specialized software to carefully model the dragon. This virtual sculpting allows infinite refinement of curves, textures such as detailed scales, horn structures and facial expressions.

- Free form: 3D printing (additive manufacturing) builds objects layer by layer. This means there are no limitations on undercuts, internal passages, or complex interlocking parts—ideal for depicting twisted dragon bodies, detailed claws, or capturing a dragon in flight.

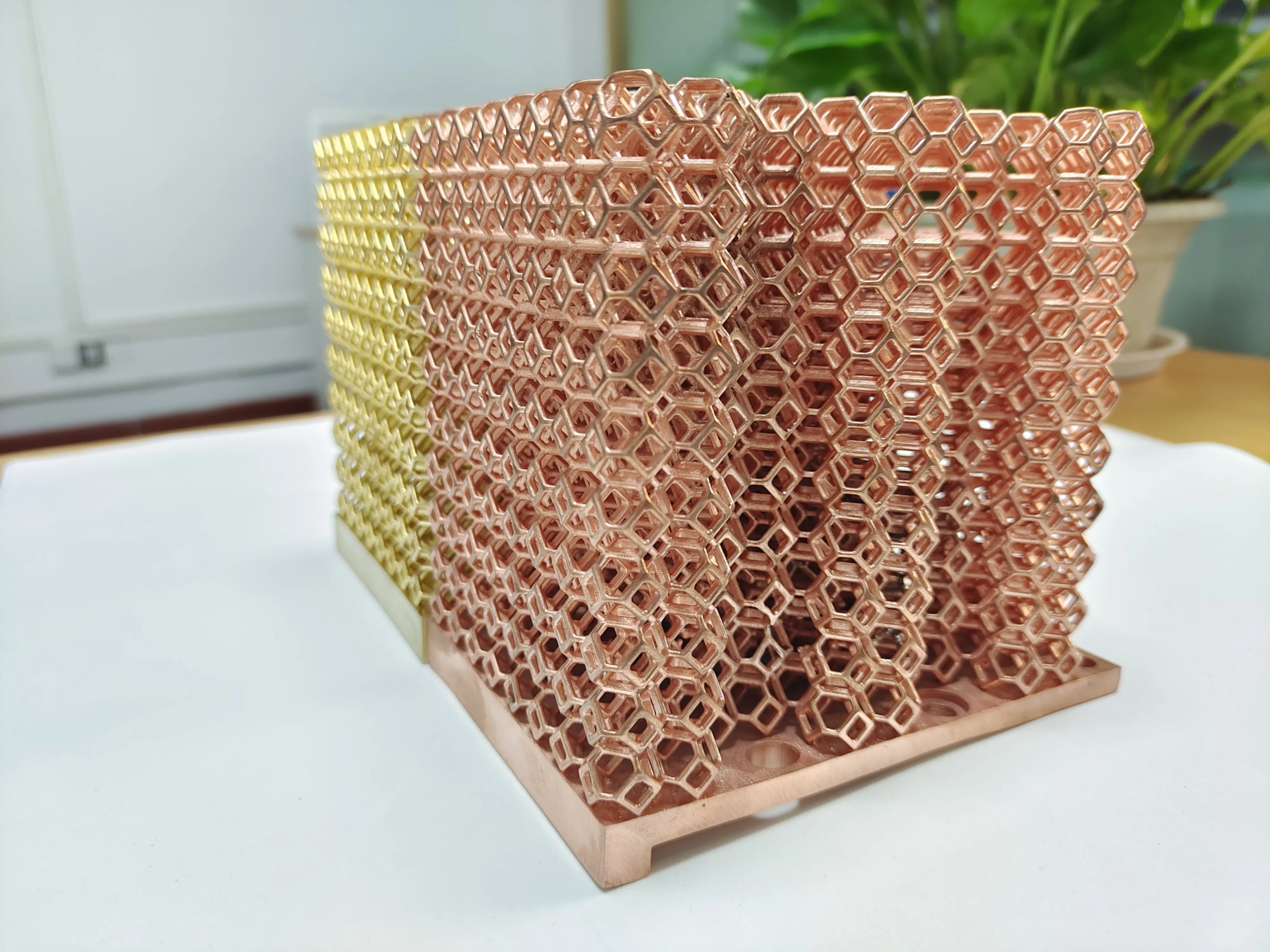

- The Embodiment of the Myth: Metal Edge: While plastic is common, reshaping solemn The processing of ancient bronze or jade required advanced metal technology, e.g. Selective Laser Melting (SLM). SLM uses a high-power laser beam to selectively fuse fine metal powder particles such as stainless steel, titanium, aluminum alloys, bronze composites, and even precious metals into solid layers. The advantages of this process are:

- The extremely fine details needed to achieve scale patterns and facial features.

- Create lightweight yet structurally complex internal lattices.

- Produce sturdy pieces perfect for display, functional fixtures, and even intricate jewelry inspired by dragon patterns.

- Unlimited size: Want a small tabletop statue or a large gallery installation? 3D printing scales easily. The digital model simply needs to be adjusted and the printer can handle the build to scale.

Bridging legend and reality: the role of professional rapid prototyping manufacturers

Transforming complex dragon CAD files into physical masterpieces requires more than just a printer. It requires specialist knowledge, precision equipment and meticulous post-processing – this is the domain of specialist rapid prototyping partners such as huge light.

Why expertise like GreatLight’s is critical for such a complex project:

- Advanced SLM features: GreatLight utilizes cutting-edge SLM 3D printers designed for high precision and repeatability. This ensures that every scale, claw tip and sculpted surface detail is faithfully rendered, even when working with demanding metals.

- Material mastery: In addition to common alloys, GreatLight offers extensive material customization and consultation. Whether it’s a bronze-style finish, the smoothness of titanium, or the brilliance of fused powders of precious metals, they can customize material selections to evoke the desired aesthetic and functional properties that perfectly fit your mythical creature.

- End-to-end problem solving: Complex myths require complex solutions. GreatLight specializes in solving challenging rapid prototyping requirements – complex castle towers, complex sculptural canopies and of course mythical beasts. Their engineering expertise proactively addresses design for manufacturability (DFM) challenges unique to additive manufacturing.

- One-stop post-production improvement: Printing is just the beginning. GreatLight’s comprehensive post-processing services are amazing Life into original printed form. This can include:

- Support deposit elimination: Heavy tools can damage delicate features. Skilled technicians precisely remove supports and carefully sand hard spots.

- Surface treatment: Polished for a mirror shine, sandblasted for an even texture, tumbled for a smooth edge – choose based on the desired final look.

- Premium finishes: Electroplating (gold, nickel, copper), powder coating, gradient scale airbrush painting, antique bronze effect patina – transform printed metal into a real work of art.

- Speed and accuracy: Rapid prototyping isn’t just about speed; This is to achieve high fidelity quickly. GreatLight streamlined the workflow from document review to final shipment, ensuring a quick turnaround without compromising the intricate details necessary to capture the essence of the dragon. Their focus is always on

custom precision machiningMeet the highest standards.

Beyond Decoration: Applications for 3D Printed Dragons

The fusion of myth and technology unlocks a variety of possibilities:

- Unique Art and Sculpture: Create stunning stand-alone pieces for a gallery or private collection.

- Cultural protection: Create exact replicas of historical artifacts or create new interpretations of traditional patterns.

- Education model: Visualize mythology, art history, or engineering principles (complexity achievable through additive manufacturing).

- High-End Interior Design/Architectural Features: Install an attractive dragon sculpture, handle or fixture.

- Innovative jewelry: Design intricate pendants, rings or statement pieces with unparalleled detail using metal additive manufacturing.

- Functional art: Make ornate bookends, lamp holders or ritual objects imbued with dragon symbolism.

- Animation/Film Prototyping: Create highly detailed physical models for stop-motion animation or reference models.

**Conclusion: The development direction of traditional technology