The Fascinating World of 3D Printed Chip Clips: A Comprehensive Guide

In today’s age of rapid prototyping and custom manufacturing, 3D printing has revolutionized even the simplest household items—like the humble chip clip. These versatile kitchen essentials now benefit from the precision, durability and design flexibility of additive manufacturing. For engineers, hobbyists and businesses, 3D printed chip holders represent the perfect combination of functionality and innovation.

Why choose 3D printed chip holder?

Traditional chip clips are mass-produced with limited designs and materials and often fail under pressure or lose their grip. 3D printing changes this dynamic in the following ways:

- Customized: Design clips for unique bag sizes or branding (e.g. logo, texture).

- Durability: Choose engineering-grade plastic or metal to withstand heat, moisture and repeated use.

- Iterate quickly: Test prototypes in hours without waiting for tooling adjustments.

Key Design Considerations

Successful 3D printed chip holders depend on intelligent design principles:

- mechanical function:

- Incorporate spring mechanisms, such as living hinges, into polymers or coil springs into metal clips.

- Optimize clamping force with ribbed jaws or silicone inserts for a non-slip grip.

- Material selection:

- polymer: Nylon (PA12) for flexibility, ABS for impact resistance, and PETG for food safety applications.

- Metal: Stainless steel (316L) or titanium with industrial grade elasticity (ideal for high temperature environments).

- Ergonomics: Curved handle and thumb pad improve comfort, while compact design minimizes storage space.

The 3D printing process: from file to completion

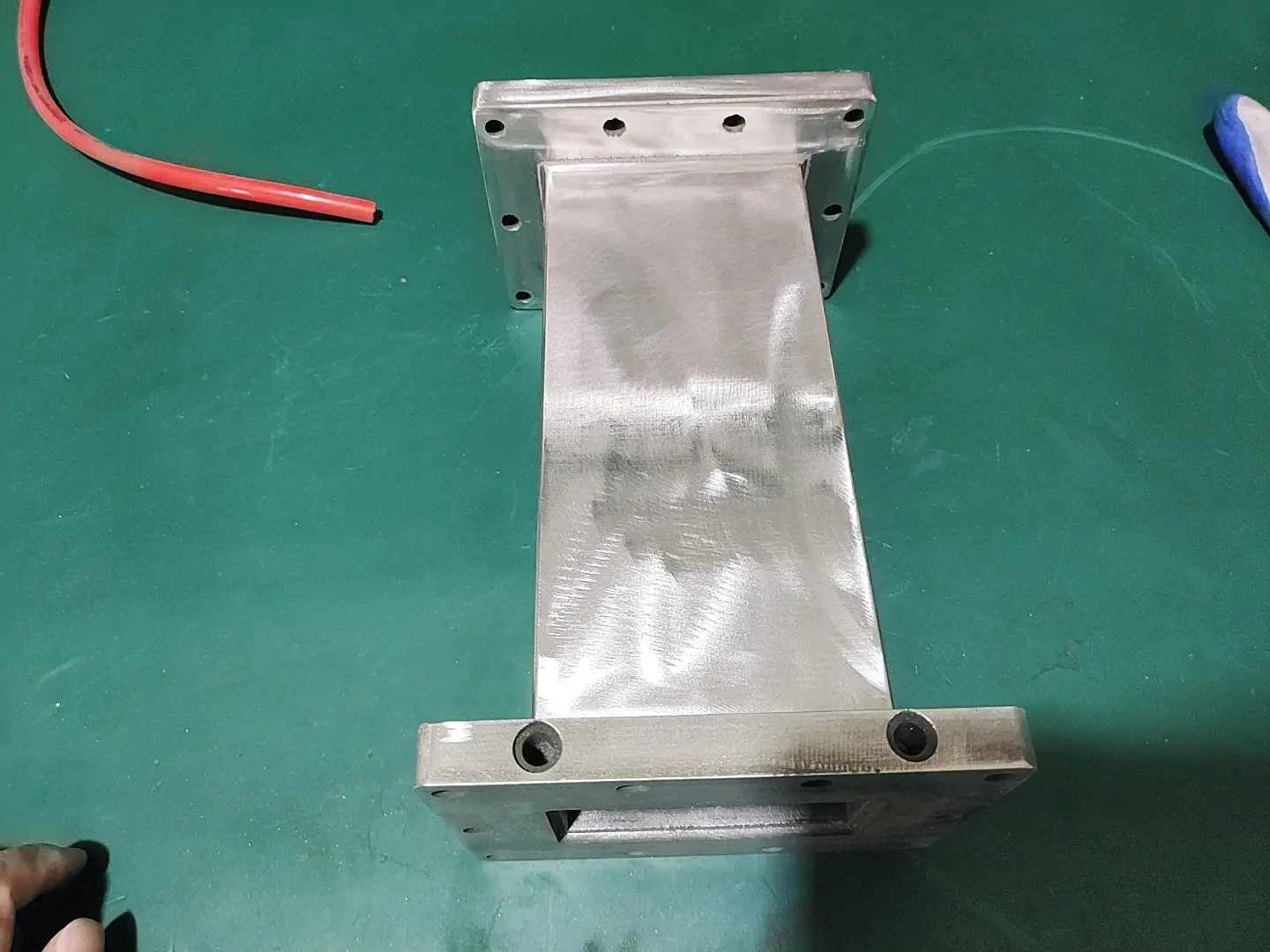

At GreatLight, we utilize advanced Selective Laser Melting (SLM) metal clip technology and SLS/Frequency Division Multiplexing For polymer variants:

- Document preparation: CAD models are optimized for print orientation to minimize supports and reduce post-processing.

- print:

- Metal: SLM printers use lasers to fuse micron-thin layers of metal powder to achieve ±0.1 mm accuracy.

- polymer: SLS creates strong, warp-resistant parts; FDM enables cost-effective prototyping.

- Post-processing:

- The supports are removed and the parts are sanded, polished or vibration tumbled.

- Metals are heat treated to relieve stress; polymers are dyed or sealed to protect against moisture.

- Quality control: Dimensional verification via CMM ensures each clip meets accurate specifications.

Practical application

In addition to sealing snack bags, the 3D printed clips also have industrial uses:

- medical: Sealed sterile packaging in the laboratory.

- aerospace: Securing cable bundles on aircraft.

- retail: Custom branded clips for promotional merchandise.

Why Choose Professional Rapid Prototyping Services?

While desktop printers are sufficient for basic prototypes, complex geometries and functional materials require industrial-grade solutions. As a leader in rapid prototyping, huge light Combining cutting-edge SLM 3D printers with deep technical expertise. Our end-to-end service ensures:

- Material diversity: From stainless steel to biocompatible polymers.

- Accuracy tolerance: ±0.05–0.1mm, suitable for mission-critical applications.

- One-stop organization: Anodizing, electroplating, powder coating and assembly.

- speed: Complete functional prototypes within 24-48 hours; production can be completed in just a few days.

We solve the toughest rapid prototyping challenges – whether you need a titanium clamp for extreme conditions or 10,000 branded units for retail.

in conclusion

The 3D printed chip clip exemplifies how additive manufacturing can breathe new life into everyday items. By leveraging customizable geometries, engineering-grade materials and precision manufacturing, companies can create products that are superior to off-the-shelf alternatives. At GreatLight, we’re committed to turning your ideas into long-lasting, innovative solutions quickly and cost-effectively. The future of functional hardware is already here, and it starts with chip clips.

Ready to prototype? Explore our capabilities or request a quote today!

FAQ: 3D Printed Chip Clips

Q1: Are 3D printed chip clips food safe?

Depends on material and finish. PETG, PP and some nylons are inherently food safe but require a smooth surface to prevent bacterial growth. GreatLight uses FDA-compliant materials and uses post-processing to seal pores.

Question 2: How is the strength of metal 3D printed clips compared with plastic clips?

Metal clamps, such as stainless steel, have excellent tensile strength and can withstand extreme temperatures. Plastic clips are lighter and suitable for moderate use. We help select materials based on stress analysis.

Q3: Can I print clips with moving parts?

Yes! Living hinges (plastic) or spring-loaded components (metal) are possible. Designed with minimal friction and optimal elasticity.

Q4: What is the turnaround time?

Prototypes ship in 1-3 days; production batches take 5-10 days. Expedited options available.

Q5: Are you responsible for design optimization?

Absolutely. Our engineers fine-tune wall thickness, support structures and kinematics for optimal performance.

Q6: Are metal 3D printed clips cost-effective?

For low-volume, high-value applications (such as aerospace), yes. We optimize builds to reduce material waste and costs.

Q7: How do I start a project?

Upload your CAD files on the GreatLight platform, or consult our team for design support. We accept STP, OBJ and STL formats.

Turn the ordinary into the extraordinary—— glow rapid prototyping. Customize your parts today at competitive prices! Contact us for a free DFM analysis.