Using 3D printing to innovate the farming of cattle: Beyond Science Fiction

Imagine a cow with leg injury to get a custom prosthesis within a few hours, or print key veterinary tools on site during a difficult calving. Although literal "3D printed cow" Possibly causing sci-fi images, additive manufacturing has changed cattle cultivation in a tangible, innovative way. Instead of replacing livestock, this technology provides farmers and veterinarians with unprecedented accuracy and efficiency.

Practical Application: 3D printing meets cows

1. Customized prosthetics and orthopedics

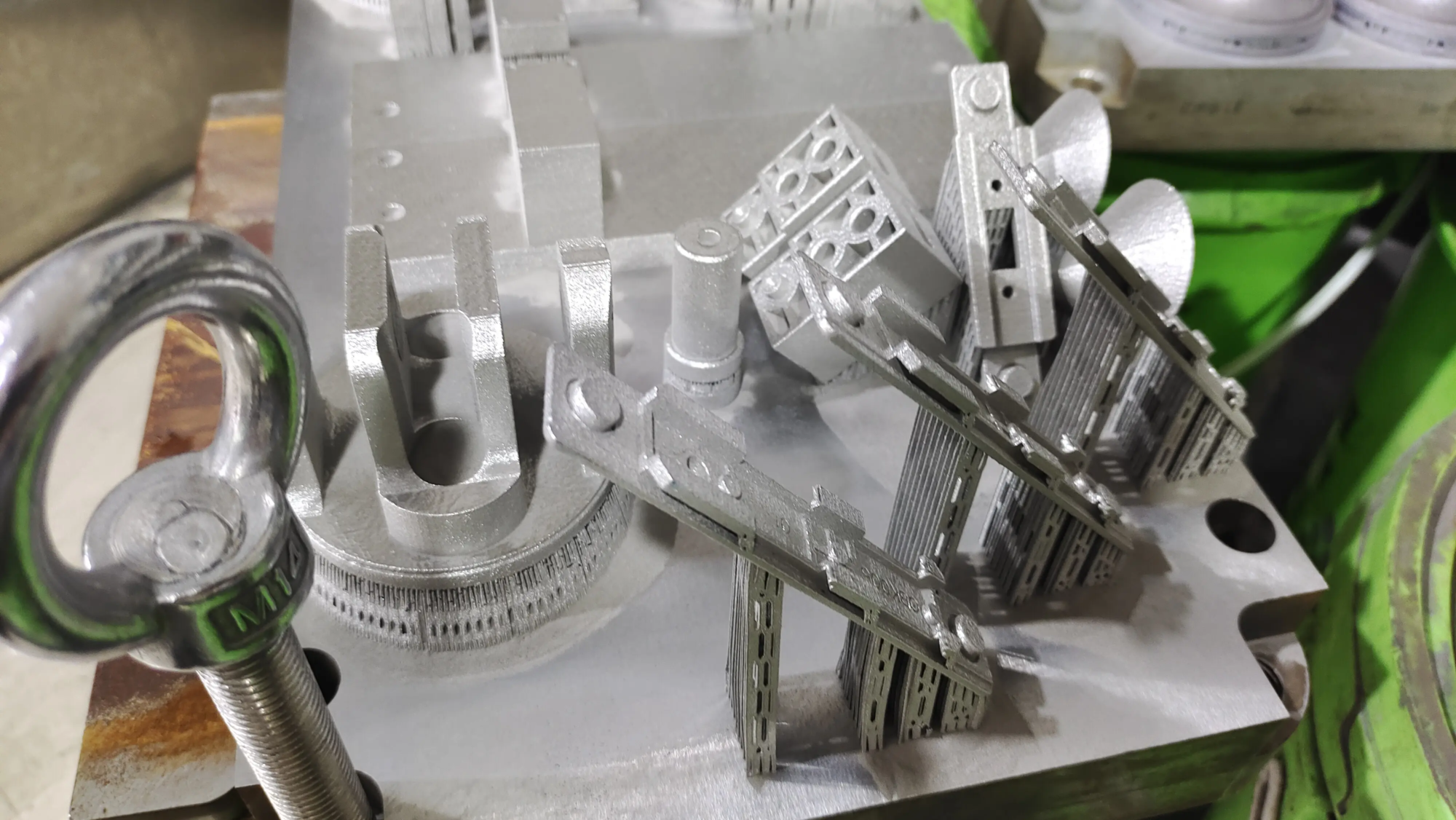

Custom prosthesis can be a lifesaving when an injury, infection or genetic condition affects the mobility of a cattle. Traditional manufacturing takes weeks and rarely explains anatomical nuances. With 3D scanning and Metal additive manufacturing (such as SLM)an 800 kg Holstein can receive titanium hoof implants optimized for weight distribution and gait-print tolerance in microns. These implants reduce tissue strain and prevent cysts.

2. Precision surgical tools and guides

Complex cattle surgery (e.g., fracture repair or cesarean section) relies on bone saws, retractors, or drill bit guides tailored to cattle physiology. Standard tools often require improvisation. 3D printing enables veterinary clinics to design and produce Patient-specific instruments overnight. SLM-printed stainless steel or titanium ingredients ensure sterility, strength and compatibility with sterilization protocols, which are essential for preventing post-infection.

3. Smart farming equipment

From ergonomic milking nozzles to ranch sensors, 3D printing enables rapid prototyping of farm hardware. Printing in dairy farm Breast fitting adapter To prevent mastitis, a feeder designed for the optimal feed dispersion reduces waste by 20%. Bonus: Spare parts for tractors or milking robots can be printed out during rupture, avoiding 4 weeks of supplier delay.

4. Biocompatible tissue engineering (frontier)

Research labs are exploring 3D-Bioprint structure For cartilage repair or skin grafting, using bioinks loaded with bovine cells. Despite years of commercial use, this can solve chronic hoof lesions or surgical complications.

Strategic Advantages

- High quantification: Solutions that adapt to each variety, weight and damage – instead "universal."

- speed: Compared with the delivery time of traditional manufacturing, tools are produced within 24-72 hours.

- Cost Efficiency: Avoid the minimum order quantity; economically print small batches of special parts.

- Reduce waste: The additive method uses only the necessary materials, trim waste and CNC processing.

- Welfare Focus: Minimize animal stress through faster interventions and precise fit.

Lead to challenges

Despite its promising prospects, there are barriers to adoption:

- Materials Science: Agricultural equipment endures extreme conditions (water, ultraviolet rays, shock). High performance alloys such as inconel or ti6al4v are essential.

- Regulatory supervision: Implants require veterinary certification for biocompatibility – work with experienced manufacturers to ensure compliance.

- Technology integration: Farm infrastructure may require IoT upgrades for CAD file processing.

These obstacles are overcome – SLM printers can obtain ISO certification results in terms of corrosion resistance and tensile strength.

Looking to the future

Trend tends to "On-demand agriculture." Future barns may house compact industrial printers, production feed scoops, vaccine syringes or joint brackets overnight. Sustainability has also attracted interest: a large number of OEM parts that narrow their carbon footprint with recycled metal printing. Currently, a focus on pragmatic tools ensures cattle get faster, more complex care – increasing productivity without sacrificing compassion.

Conclusion: Going towards a smarter animal husbandry industry

3D printing in cattle cultivation is not speculative, it is an amplification efficiency and welfare of an operational toolkit. For farmers facing labor shortages or supply chain damage, local metal AM functions provide agility. By specializing in precise SLM technology and post-processing services, manufacturers like us empower farms with affordable innovation. The goal is not science fiction cattle, but a science-supported solution that makes livestock management more resilient and humane.

FAQ: 3D printing in cattle planting

Q: Can you literally “print” the entire cow?

No, full bioprinting is still theoretical. Current applications focus on medical/technical hardware, not biological organisms.

Q: Are 3D printed veterinary tools safe for cattle?

Yes, when printed with biocompatible materials (eg, medical grade titanium (ISO 10993 certified)) and properly disinfected. Post-treatment ensures a smooth, bacteria-resistant surface.

Q: How expensive is this for small farms?

Initially, prototypes through SLM may have cost more per unit, but it has proven cost-effective over time by reducing downtime, inventory and cattle losses, especially when recycling metal powders.

Q: Which material treats outdoor conditions?

Stainless steel 316L (corrosion resistance), titanium alloy (light strength) and engineered polymers such as PEEK (for lightweight housing) can withstand UV light, mud and pressure.

Q: Can I print spare parts for my John Deere equipment?

Absolutely. Sharing a CAD file or scan, we copy brackets, gears or nozzles through SLM, which is ideal for traditional machinery with deactivated parts.

Q: Do the farm need an internal printer?

not necessarily. Cooperate with prototype services with low-volume orders. Industrial SLM systems like ours achieve production-grade results without the need for farm-side capital investment.

Q: How long does it take to make a custom cattle implant?

Normally 3-5 days: Design/scan for 1 day, printing for 1-2 days, polishing and sterilizing for 1-2 days.

Innovate your agricultural business accurately

At Greatlight, we leverage advanced SLM 3D printing to create powerful agricultural custom metal solutions – from veterinary equipment to mechanical parts. With one-stop post-treatment and material flexibility (stainless steel, titanium, aluminum), we quickly solved the prototype challenge. As a pioneer in additive manufacturing, we are committed to supporting cutting-edge agriculture. Explore faster and smarter livestock management – Contact our fast prototypes for your herd needs.