The future of display: How 3D printing is revolutionizing display cabinets

For centuries, display cabinets have been the silent guardians of our most precious objects—ancient artifacts in museums, rare collectibles in homes, cutting-edge prototypes in research and development labs. Traditionally, these enclosures have been made from wood, plastic or metal using subtractive methods, often limiting design imagination and accessibility. Additive manufacturing, or 3D printing. This transformative technology not only changes the way display cases are made; It fundamentally redefines their potential, enabling fundamental innovations that were previously impossible or prohibitively expensive. Let’s explore the exciting prospects of 3D printed display case innovation.

Breaking the rules: key innovations enabled by 3D printing

-

Unprecedented geometric freedom: Forget about rectangular boxes. 3D printing excels at creating complex, organic, and complex geometries without the constraints of traditional tools. Imagine:

- Fluid, sculptural forms: Shells that mimic natural shapes, flow around objects, or blend seamlessly with architectural elements.

- Internal structure and acrylic integration: Print complex internal supports, mounting fixtures or custom light channels directly into the structure. Seamless hybrid designs that combine printed supports with optically clear printed acrylic or polycarbonate panels are becoming a reality, creating stunning visual effects.

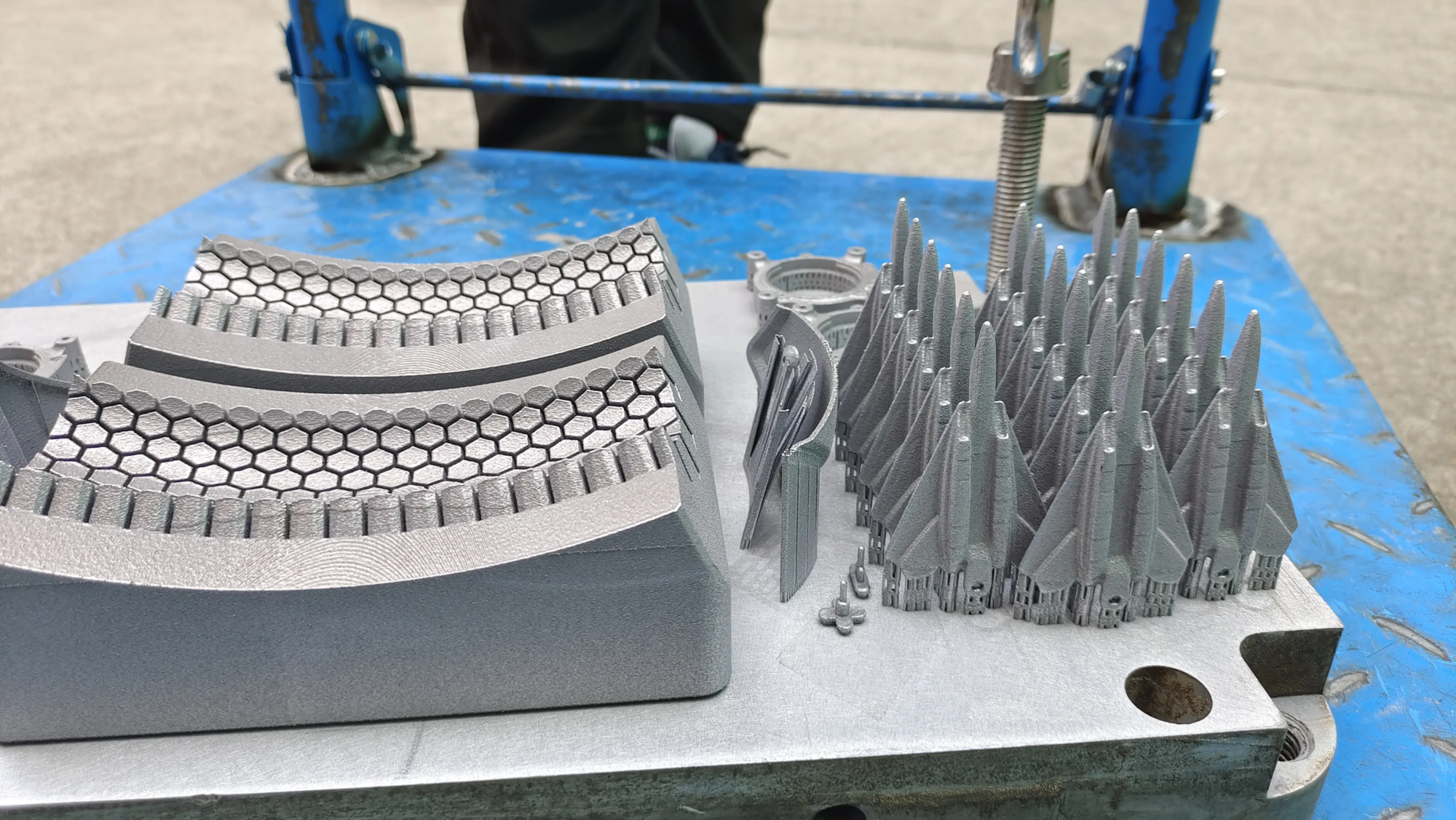

- Microlattice structure: An ultra-light yet strong outer shell is created using an internal lattice pattern that cannot be created using traditional methods.

-

Mass customization and personalization: Standardization is out; personalization is mainstream. 3D printing can cost-effectively produce one-off or low-volume products for specific needs. precise Artifact or context:

- Object-specific installation: Print custom racks, jigs or platforms that perfectly fit the unique shape, size and fragility of the items being displayed within the case.

- Brand integration: Embed logos, complex patterns, QR codes for information linking or specific textures directly into the case structure.

- Scalability: Easily expand your display cabinet design, ranging from tiny jewelry cabinets to large museum windows.

-

Complex feature integration: 3D printing enables multifunctional designs that blend form with sophisticated utility:

- Built-in environmental controls: Incorporate hollow channels within printed walls for integrating humidification/dehumidification systems or temperature control elements critical for sensitive workpieces.

- Conductive path: Wiring conduits or printed conductive tracks for LED lighting systems, interactive sensors, touch screens or security features are embedded directly into the printed structure itself.

- Self-assembly and modular design: Create complex interlocking assemblies that allow for easier shipping and efficient on-site assembly, even for large or complex boxes.

-

Advanced Materials Capabilities: In addition to standard plastics, metals open up entirely new dimensions:

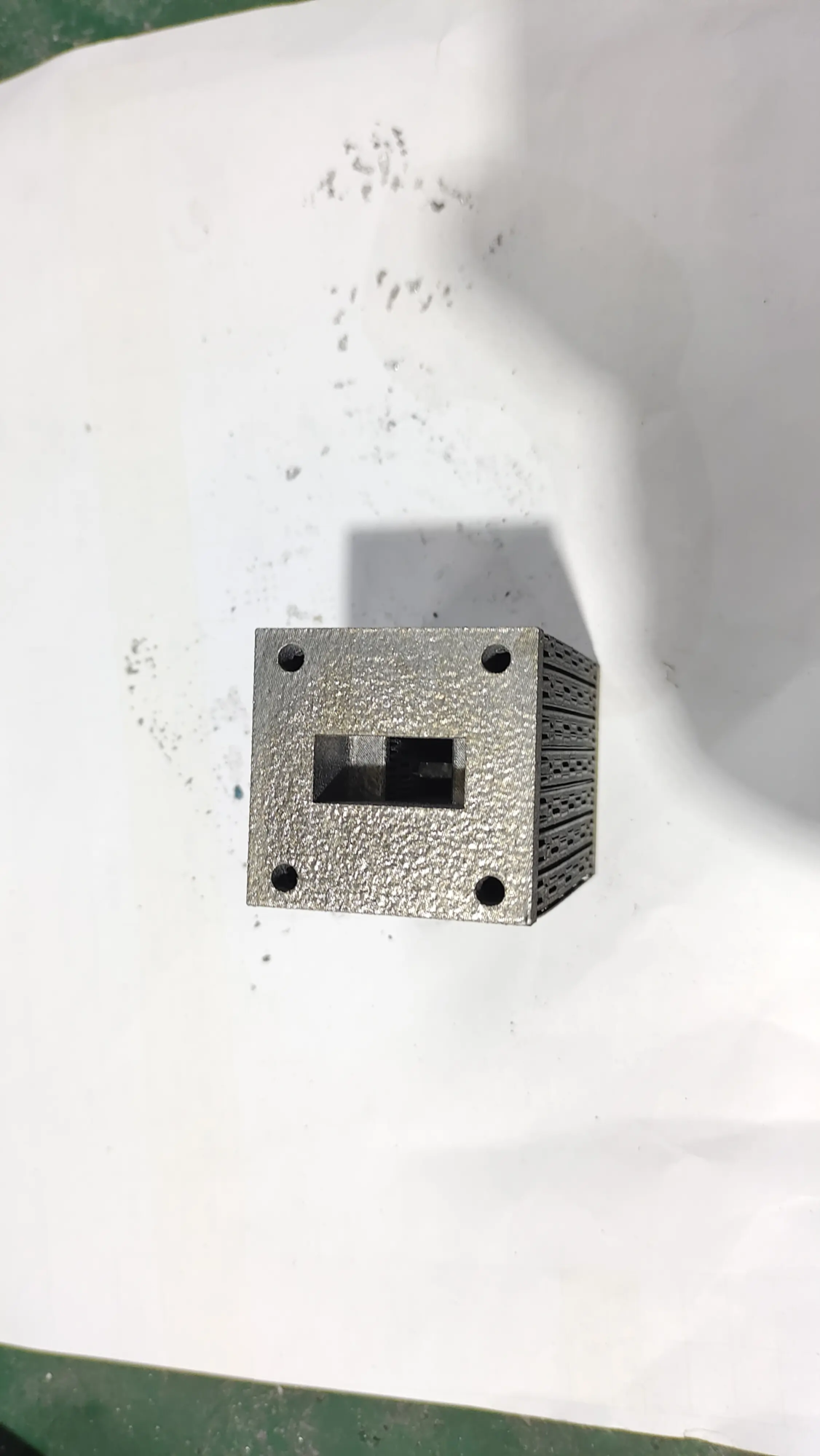

- Metal Printed Frame and Hardware: Use Selective Laser Melting (SLM) to print strong, precise, and visually stunning metal hinges, locks, mounting brackets, structural frames, and even entire boxes. Metals such as stainless steel, aluminum, and titanium offer superior strength-to-weight ratios, enhanced safety, high-end aesthetic appeal, and exceptional durability for demanding environments.

- Printing on multiple materials: Concept prototypes are made in plastic before going into metal production. Combine materials (for example, rigid supports with flexible seals) in a single print job for optimal performance.

- Special materials: Use materials with specific properties – higher temperature resistance, enhanced flame retardancy, biocompatibility (for medical displays) or customized textures.

- Breaking the formal boundaries: Designers and curators now have the tools to fundamentally rethink display cabinets:

- Non-hierarchical presentation: Moving away from isolated boxes towards seamless, integrated display systems and narratives integrated into architectural elements.

- Space integration: Cases integrate more organically with the environment, enhancing immersion rather than acting as obstacles.

- Enhanced accessibility features: Design tactile elements Enter Case structures for visually impaired visitors or interactive elements that engage users in different ways.

Tangible Benefits: Why Switch to 3D Printed Display Cabinets?

- Speed and agility: Prototype iterations are significantly faster. Significantly shortens the design-to-production cycle compared to traditional machining or forming.

- Cost effectiveness (especially complexity): Complex geometries and custom designs become economically feasible, often eliminating expensive tooling costs for low to medium volumes.

- Unleash design freedom: Translate digital designs directly into physical reality without simplification.

- Achieve perfection: Leverage digital precision to consistently install precision mounts, hardware and integrated components perfectly.

- Lightweight: Optimizing the internal structure (topology optimization) minimizes material while maximizing strength and reducing overall weight – crucial for transportation and installation.

- Sustainability: Additive manufacturing processes generally produce much less waste than subtractive manufacturing (milling, cutting).

Innovation Highlights: Key Application Areas

- Museums and Galleries: Create custom mounts for irreplaceable artifacts, integrate environmental controls, design seismic supports, and craft unique, narrative-enhancing display structures. Even if the originals are lost, digitizing delicate artifacts can allow complex scaffolding to be reconstructed.

- High-end retail and luxury goods: Enhance your brand image by developing visually stunning, highly customized display cases for watches, jewelry, fashion items or electronics.

- Collectibles and Souvenirs: Providing collectors with unique, personalized display solutions for action figures, models, sports memorabilia or art.

- Prototyping and product design: Functional display prototype for quick visualization of concepts for use in marketing, sales tools, user testing or trade shows. Functional mounting solutions for safely displaying product iterations.

- Architectural interior design: Create integrated display niches, custom shelving or functional art installations.

- Education and Science: Create durable models, interactive displays with embedded sensory elements, or specialized housings for scientific instruments.

- consumer goods: Turn to accessible 3D printed shelving inserts and purpose-built display racks.

in conclusion

3D printing is moving beyond simply making novelties and firmly positioning itself as this A transformative tool for future display solutions. It breaks traditional limitations and enables designers, curators, retailers and collectors to realize concepts once considered unfeasible. From unparalleled customization and complex functional integration to radical formal possibilities and the powerful utility of metal printing, the innovations enabled by additive manufacturing are reshaping the way we represent, protect, and interact with valuable objects.

As materials advance, precision increases, and metal printing capabilities become more common, 3D printed display cabinets will evolve from professional solutions to the best choice for different industries. They represent the perfect fusion of cutting-edge technology and the timeless need to showcase the things we hold dear, ensuring that important items are presented with unparalleled elegance, safety and environmental integrity.

FAQ: 3D Printed Display Cabinets

Question 1: Are 3D printed display cases strong enough, especially for valuable or heavy items?

Answer: Of course. Strength depends largely on the material and printing technique. Functional plastics such as ABS, nylon or polycarbonate offer excellent durability. For superior strength and safety, Metal Printing (SLM) Housings and hardware produced using stainless steel, aluminum alloys or titanium can rival or exceed conventionally machined metal parts. Advanced lattice and topology optimized design maximizes strength while minimizing weight.

Q2: How does the cost compare with traditional glass/metal/wooden boxes?

A: For standard, simple, high-volume cases, traditional methods (such as metal fabrication) may still be cheaper. However, 3D printing is extremely cost-effective in:

- Complex geometric shapes: Eliminate expensive moulds/dies/tooling.

- Customized/Customized Design: There is no unit tool cost penalty.

- Low to medium capacity: Ideal for prototypes, museum artifacts or specialty retail.

- Integrated features: Flush mount/light/system eliminates assembly costs.

High-volume standardized housings are still less expensive via injection molding or large-scale CNC cutting/assembly.

Q3: Do 3D printed boxes really look professional?

A: Yes, as long as there is the correct process and post-processing. Printed components can be sanded, painted, polished, powder coated, electroplated or anodized (especially for metals) to achieve a near-perfect, high-end finish that rivals traditional manufacturing. Techniques such as vapor smoothing (used on plastics) can provide optically clear or ultra-smooth surfaces.

Q4: Can I get an optically clear display cabinet made by 3D printing?

Answer: Directly print large-panel optical quality glass? unreliable However. However, acrylic or polycarbonate panels printed with specialized printers can provide sufficient clarity for many applications. Cutting-edge innovation involves printing highly complex non-optical frames, brackets and integrated systems designed to safely house traditional Optical grade acrylic or glass panels, combining the best of both worlds.

Q5: How long does it take to get a customized 3D printed display cabinet?

A: In most customization scenarios, much faster than traditional methods. Once the design is digitally finalized:

- Prototyping: Iterations can be completed in hours/days.

- Simple case: It may take several days.

- Highly complex/large/metal housing: Depending on the size, material and complexity, it can take anywhere from a few days to a few weeks, but it’s still much faster than overseas tooling or custom hand-making.

Professional manufacturers such as glow rapid prototyping Focus on using advanced SLM metal printers and finishing capabilities to speed up this process.

Q6: What documents do I need to provide?

A: You need a 3D CAD file – usually in a format such as STEP, IGES, STL or OBJ. Reputable manufacturers such as huge light Cases can also be designed for you based on concept sketches or detailed specifications. Make sure the design takes into account the weight of the object being displayed, installation requirements, environmental needs (humidity/sealing), and desired aesthetics/materials.

Q7: Who provides high quality metal printed display cabinets?

For truly strong, complex and high-quality display cases or components that require metal strength and precision, work with a manufacturer with advanced technology Selective Laser Melting (SLM) Technology is crucial. company likes glow rapid prototyping Provide end-to-end solutions:

- Expert design consultation and optimization

- Advanced SLM metal printing (stainless steel, aluminum, titanium)

- Comprehensive post-processing (heat treatment, precision CNC machining integration, finishing/painting/electroplating)

- One-stop production from concept to final assembly

With capabilities for rapid prototyping and custom precision machining, Gretel provides tailor-made solutions Meet demanding display cabinet applications at a competitive price.

Ready to bring unparalleled innovation to your display? Contact GreatLight Rapid Prototyping today to discuss your vision. Take advantage of our advanced SLM metal printing capabilities and full range of finishing services to create a truly unique, functional and stunning display case that will captivate your audience and protect your treasures. Start your custom precision project today!