Empowering Paws: The Transformative Impact of 3D Printed Dog Wheelchairs

For dogs who face mobility impairments due to age, injury, or neurological conditions such as degenerative myelopathy or intervertebral disc disease (IVDD), maintaining independence and quality of life is crucial. Traditional wheelchairs have been a lifeline for people, but they often have limitations in terms of fit, comfort and adaptability. 3D printing technology opens up unprecedented possibilities for canine mobility solutions. This revolution isn’t just about moving the wheels; It’s designed to restore happy movement and is perfectly tailored for each unique furry friend.

Rethinking canine mobility: beyond one size fits all

Standard dog wheelchairs usually come with an adjustable aluminum frame and universal sized brackets. While fully functional, they may come with complex body types, nuances in size (especially with very small breeds), pressure point discomfort, or dogs with unique gait requirements. An ill-fitting device can cause bruising, limited movement, or even cause the dog to give up using the device altogether.

This is where additive manufacturing or 3D printing fundamentally changes the game. Its core strength lies in custom made and Complex design freedomdirectly solves the shortcomings of mass-produced carts.

Key innovations driving the 3D printed wheelchair revolution:

- Ultra-personalized fit and comfort: A veterinarian, orthopedic specialist or professional wheelchair designer can create a digital model using a scan of the dog’s body (3D scan or precise measurements). 3D printing transforms this model into perfectly fitting wire harness interfaces, frame connectors and support structures. This minimizes pressure points, distributes weight evenly, and accommodates abnormal anomalies such as spinal deformities or amputations more effectively than adjustable metal clips.

-

Complex geometry enhancements:

- Ergonomic seat belt components: 3D printing allows for the creation of contoured chest and back panels that closely fit the dog’s anatomy, maximizing stability without restricting breathing or natural shoulder movement.

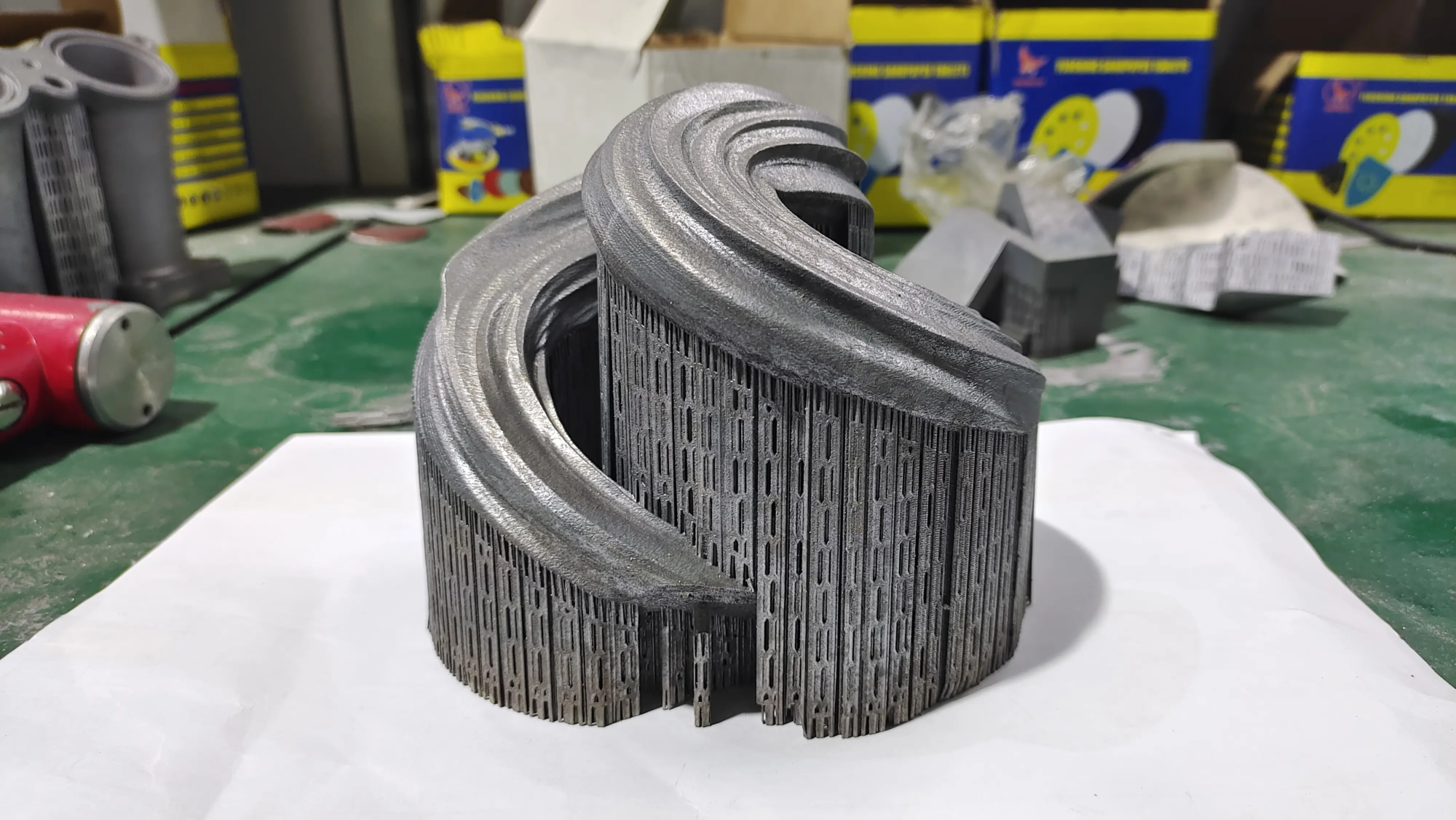

- Optimized weight distribution: Frame elements can be designed using lattice structures or topology optimization algorithms. This makes the assembly very strong when needed, but the overall weight is super light, taking the load off the dog.

- Comprehensive features: Designers can integrate features directly into the printed part, such as custom pad mounting for post-operative cart installation, specific suture locations, or even special channels for safety harnesses.

-

Material Advancements and Versatility: While lightweight polymers such as nylon (PA12) or specialty PETG are often used for frames and harness interfaces, the range of materials available for 3D printing is very wide:

- Medical Grade Polymers: Provides biocompatibility and superior sterilization capabilities for components with long-term skin contact.

- High performance polymers: Materials like PEEK offer excellent strength-to-weight ratio and chemical resistance for demanding applications.

- Flexible filament: TPU (thermoplastic polyurethane) can be printed to create flexible cuffs, padding elements or shock mounts for a smoother ride that would be difficult to achieve seamlessly with rigid manufacturing.

-

Rapid prototyping and iteration: Designing the perfect wheelchair isn’t always linear. 3D printing excels at rapid prototyping. Initial designs can be quickly and cost-effectively printed, tested on dogs, digitally adjusted based on feedback (from dogs and clinicians/pet parents), and then reprinted—all within days or even hours. This iterative process ensures the final product is truly optimized for dog comfort and mobility much faster than traditional manufacturing methods.

- Accessibility and maintenance: While custom 3D printing involves design expertise, the democratization of 3D printers has empowered passionate individuals, rescue organizations, veterinary schools, and professional workshops around the world. A common scenario for owners: A cracked plastic bracket on a traditional stroller usually means the entire unit needs to be replaced. For 3D printed wheelchairs, if the design files are available, damaged brackets can be quickly and cheaply reprinted, significantly extending the life of the stroller.

Who made this happen? The role of advanced manufacturing partners

Bringing these complex custom solutions to life requires expertise beyond desktop printer enthusiasts. Accuracy, biocompatibility verification, structural integrity analysis, and reliable production require industrial-grade technology and technical proficiency. This is where professional rapid prototyping manufacturers become important partners.

Advantages of working with a partner like GreatLight:

- Advanced metal and plastic features: Professional rapid prototyping manufacturers have advanced equipment such as Selective Laser Melting (SLM) Printer For creating strong, complex metal parts (such as high-stress joints or custom hardware) and high-resolution polymer printing (SLA, SLS, FDM). This ensures that every part of the wheelchair, from the biocompatible interface to the load-bearing axle, meets strict standards.

- Engineering expertise: They bring deep materials science knowledge (ensuring the use of FDA-compliant resins or certified metals where needed) and structural design validation expertise, working closely with veterinary orthopedic experts to achieve optimal results.

- End-to-end solution: In addition to printing, full-service providers offer comprehensive Post-processing: Smooth surfaces for skin comfort, vapor-smooth nylon for hygiene, application of biocompatible coatings, sterilization, precise machining of mating surfaces and ultimately quality assurance – providing a complete, ready-to-use solution. (Disclaimer: GreatLight embodies this ability).

- Scalability and speed: They can quickly and seamlessly move from a single prototype to low-volume production, ensuring timely delivery in the event of an emergency.

Real-world impact: A wagging tail tells a story

The impact is global:

- Animal Sanctuary: Affordable custom strollers for disabled rescued animals with unique needs.

- Veterinary Rehabilitation Center: Solve complex mobility challenges for patients that cannot be met by off-the-shelf solutions.

- Pet owners: Provides increased mobility and happiness for beloved companions such as senior dogs with weaker hind legs, pets recovering from trauma, or pets with congenital disabilities. Online communities show off countless dogs experiencing Zoomies all over again, thanks to a 3D printed stroller that fits perfectly.

The future of four wheels

Its trajectory is incredible:

- Sensor integration: The printed components can house sensors that monitor gait, pressure points or activity levels, feeding data back to veterinarians for objective assessment.

- Smart material development: Materials that respond to temperature, humidity or pressure to enhance comfort or self-adjusting support.

- AI-driven design optimization: Automatically generate optimized structures based on biomechanical analysis of dog-specific gait patterns.

- On-demand local manufacturing: Distribute digital designs worldwide for licensed printing and close to the dog’s location.

Conclusion: A paradigm shift in compassionate care

3D printing is more than just a novel dog wheelchair manufacturing technology; it represents a paradigm shift toward truly dog-centric mobility solutions. It enables dogs to regain mobility with dignity and joy by enabling unprecedented innovations in customization, comfort and functionality. It transforms the wheelchair from a purely functional aid into a carefully designed extension of the dog’s own body. Working with dedicated, highly skilled rapid prototyping manufacturers ensures these innovations can be realized safely, efficiently and with high quality – turning what was once science fiction into a reality that changes the lives of our four-legged companions every day.

Frequently Asked Questions and Answers about 3D Printed Dog Wheelchairs:

-

Q: How much does a custom 3D printed dog wheelchair cost?

one: Costs vary widely depending on the size of the dog, the complexity of the condition, the materials chosen (e.g., standard polymers vs. biocompatible/absorbable), and the expertise of the provider. Simple harness interfaces start at about $200-$400, while complex full-frame strollers can start at $800-$2500+. While the upfront cost may be higher than some basic adjustable strollers, the unparalleled fit, comfort, durability, and impact on the dog’s quality of life often make it a worthwhile long-term investment. -

Q: Is 3D printed plastic strong enough for active dogs?

one: Absolutely. Professional-grade 3D printing uses engineering-grade thermoplastics (such as PA11, PA12 nylon, PETG-CF) or biocompatible resins specifically selected for strength, impact resistance, and durability. These materials undergo rigorous testing. Advanced technologies such as Selective Laser Sintering (SLS) produce strong isotropic parts. Design strategies (lattice structure, optimized geometry) further enhance strength while minimizing weight. Metal parts (via SLM) provide ultimate strength when needed. -

Q: What if my dog gets older, or their condition changes? Is the wheelchair adjustable?

one: While the perfect fit 3D printed harness interface provides maximum comfort, growth or significant condition changes will require adjustments. The advantage is quick redesign and reprinting. Suppliers can often digitally modify original design files and print new components (such as larger harness sections or modified frames) relatively quickly, often faster and more accurately than adapting traditional carts built with universal brackets. -

Q: How long does the entire process take from start to finish?

one: Timetable includes consultation/measurement/scanning (1-5 days), design (3-7 days), prototyping/testing iterations (varying from 1-2 weeks), and final production + post-processing (3-7 days). Total time is usually 2-6 weeks. Complex cases or iterative fits may take longer. Reputable providers will prioritize urgent cases. -

Q: Are 3D printed parts comfortable and safe on my dog’s skin?

one: Professional suppliers prioritize safety and comfort. The polymers used are selected/validated based on skin contact compatibility. Post-processing steps are crucial: parts are carefully smoothed (steam smoothing, sanding) to remove rough edges, thoroughly cleaned, and possibly given a biocompatible coating. Strict quality checks ensure there are no sharp points or irritants. Flexible material (TPU) is also strategically used for added comfort. - Q: If I think my dog needs a custom 3D printed wheelchair, where do I start?

one: Start with a thorough consultation with your veterinarian or veterinary orthopedic/rehabilitation specialist. They can assess your dog’s specific needs, suitability for a wheelchair, and may recommend a designer or company that specializes in custom veterinary mobility solutions. Look for suppliers who demonstrate expertise in veterinary orthopedics and advanced additive manufacturing. A reputable provider will require detailed measurements, photos, videos or scans.

Experience the difference accuracy makes: The company, which specializes in advanced rapid prototyping, brings the industrial-grade technology and deep engineering expertise needed to realize the full potential of 3D printing in canine mobility. This means safer, stronger, more comfortable solutions that truly change lives, one step at a time.