With the advent of 3D printing technology, the world of body modification has witnessed a major transformation. One of the innovative applications of this technology is the creation of a 3D printed ear hole gun. These devices revolutionize the way piercing is done, providing a more precise, safe and hygienic experience for those who want to pierce the ear. In this article, we will dig into the world of 3D-printed ear-piercing guns, exploring their benefits, features, and roles in rapid prototyping.

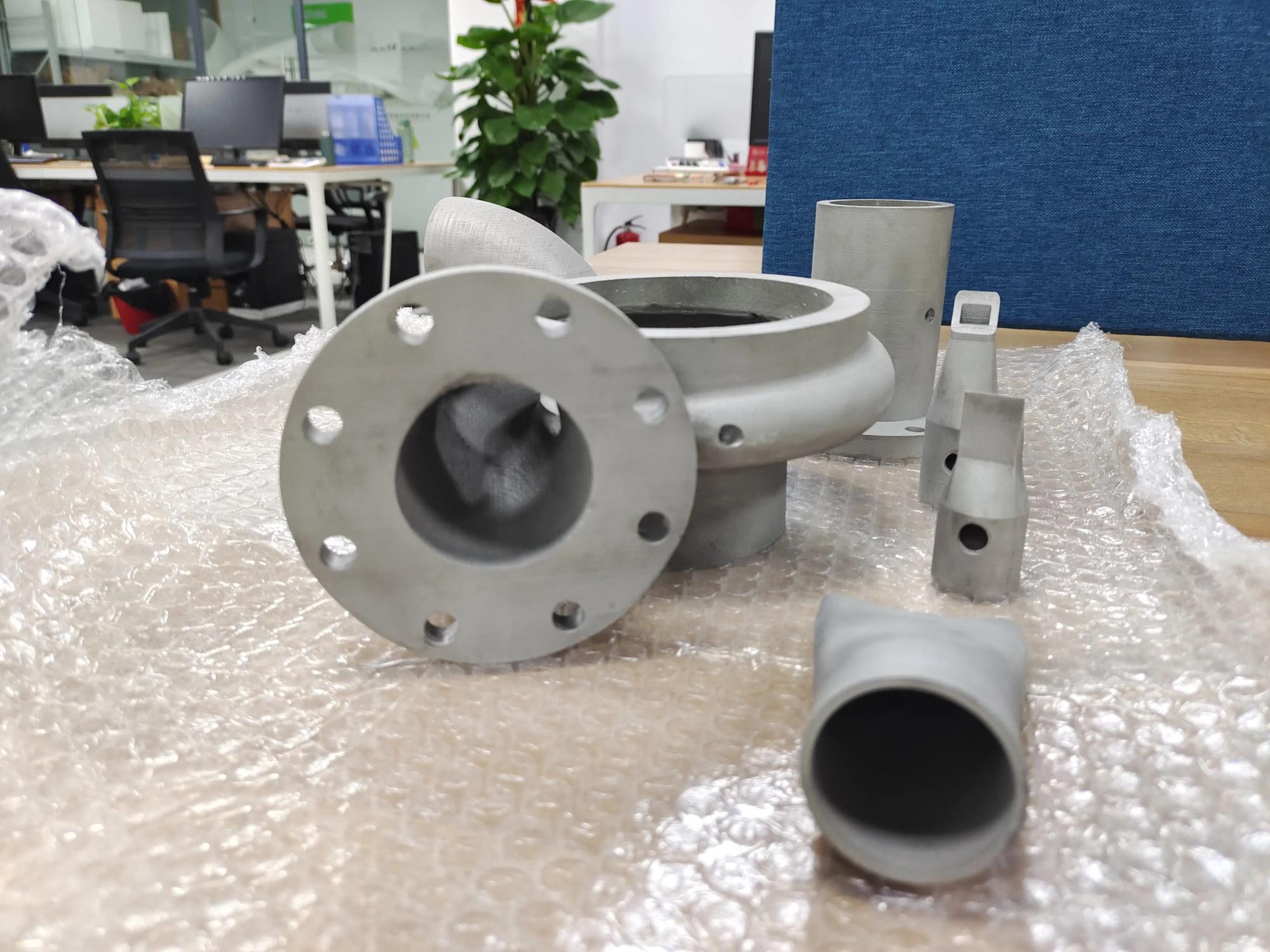

The traditional ear piercing process often involves the use of a manual gun that can be tedious and may not provide the accuracy required for safe and accurate perforation. On the other hand, the design of the 3D-printed ear perforated gun is accurate and accurate. These devices are made using advanced 3D printing techniques such as selective laser melting (SLM), which allows the creation of complex geometries and complex designs that cannot be produced by traditional manufacturing methods.

The use of SLM 3D printing technology enables durability and resistance to wear and tear. This process involves layer by layer melting of metal powder, resulting in a strong and strong structure that can withstand the stringency of reuse. Additionally, the accuracy of 3D printing technology allows the creation of custom ear perforated guns to meet specific needs and preferences.

Rapid prototyping plays a crucial role in the production of 3D printed ear hole guns. Companies like professional rapid prototyping maker Greatlight use advanced SLM 3D printers and production technology to solve rapid prototyping of metal parts. Their one-stop post-processing and finishing services ensure that the final product meets the highest standards of quality and accuracy. With the ability to quickly customize and handle most materials, Greatlight has established itself as one of the best rapid prototype companies in China.

There are many benefits of 3D printing headphone guns. They provide a more precise and controlled puncture experience, reducing the risk of human error and subsequent complications. Additionally, these devices are designed with hygienic in mind, with smooth and easy-to-clean surfaces that minimize the risk of infection. Using 3D printed ear hole guns can also create custom perforations, allowing individuals to express their unique style and preferences.

In short, the 3D printed ear piercing gun completely transforms the world of body embellishment, providing a more precise, safe and hygienic experience for those who want to pierce the ear. The use of rapid prototyping and advanced 3D printing technologies has enabled the creation of customized and durable devices to meet specific needs and preferences. As technology continues to evolve, we can expect to see further innovations in the field of 3D printed ear piercing guns, thus providing individuals with more choices and opportunities for self-expression.

FAQ:

Q: What is the process of creating a 3D printed ear piercing gun?

A: The process involves the use of selective laser melting (SLM) 3D printing technology, which melts metal powders layer by layer to create a strong and sturdy structure.

Q: What are the benefits of using a 3D printed ear hole gun?

A: Benefits include a more precise and controlled perforation experience, reducing the risk of human error and custom perforation to cater to various styles and preferences.

Q: How to ensure 3D printed ear hole guns ensure hygiene and safety?

A: These devices have smooth, easy-to-clean surfaces that minimize infection risk and are designed with a sanitary design in mind to provide a safe and sterile perforation experience.

Q: Can I customize my 3D printed ear piercing gun?

A: Yes, companies like Greatlight offer customized fast prototype services that allow you to create devices that meet your specific needs and preferences.

Q: What is the future of 3D printed ear piercing guns?

A: With the continuous development of technology, we can expect to see further innovation in this field, thus providing individuals with more opportunities and opportunities to self-express and customize perforations.

ISO 9001 Factory