The Future of Fragile Packaging: How 3D Printed Egg Cartons Cracked Innovation

Incredible egg carton. For decades, it has been a simple, often overlooked packaging design. But what if these basic containers can be smarter, more sustainable and tailored to their content? Enter the world 3D printingThis technology is designed to revolutionize egg packaging like never before with customization, efficiency and eco-friendliness. For packaging designers, agribusinesses and innovators, 3D printed egg cartons represent fertile ground mature exploration of the ground.

Why 3D printing? Unleash design innovation

Traditional egg cartons face inherent limitations. Mass production of molds is expensive and inflexible, limiting design changes. 3D printing breaks these constraints:

- High quantification: Design cartons for sizes of specialty eggs – quail, duck, giant chicken or custom made legacy varieties. Create unique brand elements or ergonomic grips that are directly integrated into the structure.

- Quick Prototyping Instant Production: Test and iterate the design in a few days rather than months. Refined size, buffer structure, ventilation mode or stacking mechanism without changing tools.

- Multifunctional design: Integrate features such as automatic egg counting windows, embedded QR codes, traceability QR codes, recipe card compartments and even integrated humidity sensors.

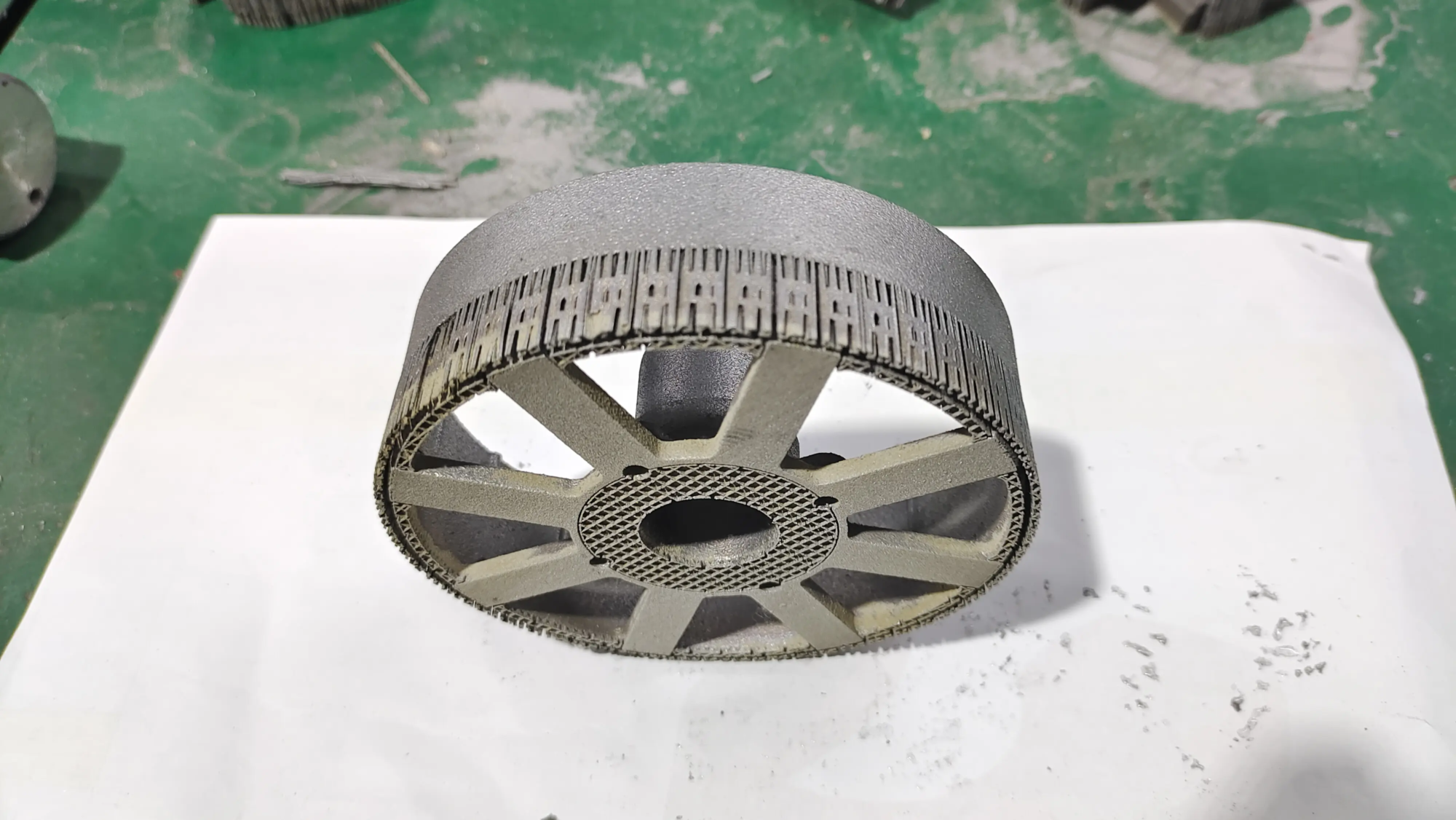

- Optimized performance: Use precisely the internal lattice structure of the generated design. Create areas with variable density/damping to provide maximum protection with minimal material cost. Optimize airflow to extend freshness.

Beyond Plastics: Exploring the Materials Vision

Although traditional cartons use molded pulp or polystyrene, 3D printing opens a different library of materials for specific needs:

- High-performance polymer (prototype): ABS, nylon or PETG are used for durable functional prototypes that can be tested in the real world form and functionality. Greglight can professionally guide the selection of materials for rigorous testing.

- Food safe and sustainable filaments (limited running/customized): An emerging biocomposite made from FDA-approved food grade PLA, RPLA (recycled) or made from corn starch, algae and even coffee grounds. Ideal for artisan producers or specific retail displays.

- Mold master creation (Popular production bridge): It is crucial to scale up. Metal 3D printing (such as SLM) Expert in producing complex conformal cooling Injection mold Directly from digital design. Greatlight’s SLM technology creates these efficient, durable metal molds that greatly reduce cycle time and improve the quality of parts in old pulp or plastic injection processes.

Sustainability factors: Reduce waste and higher efficiency

3D printing is strongly aligned with the circular economy goals:

- Local production: Print cartons on demand, close to distribution points, reducing transportation emissions and warehousing overhead.

- Resource minimization: Compared to the subtraction method, additive manufacturing uses only the materials required for the final geometry. Optimized lightweight structure further reduces material consumption.

- Reduce waste: There is no inventory risk associated with large-scale production. Print the exact number required.

- Material Innovation: Leverage rapidly developing biodegradable and recyclable printed materials. Closed-loop recycling systems have become a reality for printed plastics.

- Durable Tools: Metal 3D printing molds last longer and are executed more efficiently, thereby enhancing the sustainability of quality production solutions.

GRESTHERMENG: Your Egg Carton Innovation Partner

For pioneers who are preparing to convert egg packaging, Great Provide the full range of 3D printing expertise:

- Advanced Rapid Prototyping: Take advantage of our state-of-the-art SLM and Polymer Printers Create a functional prototype. Test your innovative carton design quickly and cost-effectively according to our expert guidance. Iterate until perfect.

- Precision metal tools: Do I need to use quantitative bridging innovation? Greatlight Usage Industrial grade SLM technology Generate high-performance, complex conformal metal injection molds. These molds have improved cooling efficiency and life by traditional methods and are used to produce egg cartons on a large scale, but all have excellent results.

- Materials Science Proprietary Technologies: Our team recommends the use of optimal materials, whether it is for durable prototypes, sustainable end-use cartons for niche markets, or printed resins that are compatible with food contact surfaces with optimized performance.

- One-stop solution: From CAD design consultation to prototyping, creating mold (if needed) and advanced finishing/sealing of prototypes, Greatlight manages the entire process seamlessly. Focus on your vision; we deal with complex manufacturing.

Conclusion: Opening a new era of packaging

3D printing is far from the novelty of egg cartons. This is the key to unlocking the new paradigm. It empowers the transition from a universal, cookie-cutter solution to a smart, sustainable and tailor-made packaging. From enabling overburning designs for small farmers to optimizing mass production with advanced metal printing tools, applications are very wide.

Whether you are developing the next generation of compostable packaging, luxury demonstration boats, or unique molds produced injectable style, 3D printing provides the agility and precision required. exist GreatWe combine cutting-edge SLM metal printing, multi-function polymer systems, deep material knowledge and end-to-end manufacturing support to transform your revolutionary egg carton concept into a tangible reality. Don’t get used to yesterday’s cartons. Innovative intelligence. Sustainable design. The prototype is fast. Partner well and crack code to the future of packaging.

FAQ: 3D printed egg cartons

FAQ: 3D printed egg cartons

Q1: Can 3D printed egg cartons be used directly to store food-grade eggs?

- one: Strict regulations apply for long-term contact with food directly. although Food grade filaments (such as specific FDA-approved PLA resins) Existing, they are suitable for direct food contact for a long time and are easy to effectively disinfect for reuse are key considerations. Excellent 3D printing prototype,custom made Short-term packaging (for example, boutique sales) or Generate mold For mass production (e.g., for injection-type food-safe polypropylene or pulp molding). Always consult material safety data sheets and regulatory guidelines.

Q2: Are 3D printed cartons as protective as traditional cartons?

- one: When correctly designed, they can provide Superior protection. The main advantage of 3D printing is the ability to design and print complex internal lattice structures or variable density region optimization calculations to achieve uniform buffering that affects absorption and weight distribution, possibly exceeding traditional designs. Prototyping allows for actual drop test verification.

Question 3: Is 3D printing cost-effective for large-scale egg carton production?

- one: Currently direct printing 3D printing millions of cartons Low competitiveness For large quantities of commercial production rather than molding pulp or mass injection molding. Its advantages shine prototype,,,,, Customization/short-term production (Craftsman Farm, Unique Eggs), it is crucial Production efficient tools. Metal 3D printing (SLM) optimized injection molds with complex shapes that significantly improve efficiency and quality exist The quality production process itself.

Q4: Materials usually used for 3D printing cartons/molds?

- one:

- Prototype carton: PLA (including ecological variants), PETG, ABS, nylon and other polymers. The choice depends on the durability, flexibility and sustainability goals required.

- Production tools (mold): Metal alloys (stainless steel, tool steel, aluminum alloys) are printed using selective laser melting (SLM) to provide high strength, heat resistance and complex conformal cooling channels.

- Food grade prototype/specific use: FDA approved specialty resin/block with proper post-processing/sealing.

Q5: How does Greatlight specifically help me develop 3D printed egg carton solutions?

- one: Great lighting provides comprehensive Rapid prototyping and manufacturing services:

- Design consultation: Advice on printability and optimal design strategies for protection and manufacturing.

- Rapid prototyping: Print function carton prototypes are quickly tested and verified.

- Advanced Tools: Use our industry SLM printer Create high-performance, durable, conformal metal injection molds for your mass production needs.

- Material expertise: Recommended for the best material for prototypes, niche end use or mold life and performance.

- End-to-end process: Includes finishing, sealing (for prototypes) and quality assurance.

Q6: Are 3D printed plastic cartons recyclable/biodegradable?

- one: It depends to a large extent on the specific material. PLA Under certain conditions is industrial compost that can be compostable, but specialized facilities are usually required. RPLA (Recycling PLA) exist. Petg Usually recyclable (#1 plastic). Always check the properties of selected filaments/resin. The use of recycled content or biologically based materials can significantly enhance sustainability. Designing disassembly and supporting local recycling streams is crucial.

Q7: How durable is 3D printed cartons compared to pulp?

- one: Polymers such as PETG, nylon or ABS usually provide significant provision High structural stiffness and resistance to crushing When printing at sufficient density, the pulp is more recycled. They are also water resistant. However, pulp is still widely recyclable. The benefit is tailored protection and innovative design possibilities, rather than just direct matching of pulp features.