The world of 3D printing has been growing rapidly, and new and innovative applications are discovered every day. In recent years, this application has attracted attention, which is the use of 3D printing technology to store eggs. This method shows great promise in keeping eggs fresh and quality, and it is a field of Greatlight for a professional rapid prototyping manufacturer.

Greglight, with its advanced SLM 3D printer equipment and production technology, has been professionally solving the problem of rapid prototyping of metal parts. The company’s expertise in custom precision machining and one-stop post-processing and completion services makes it an ideal partner for businesses looking to leverage 3D printing for egg storage.

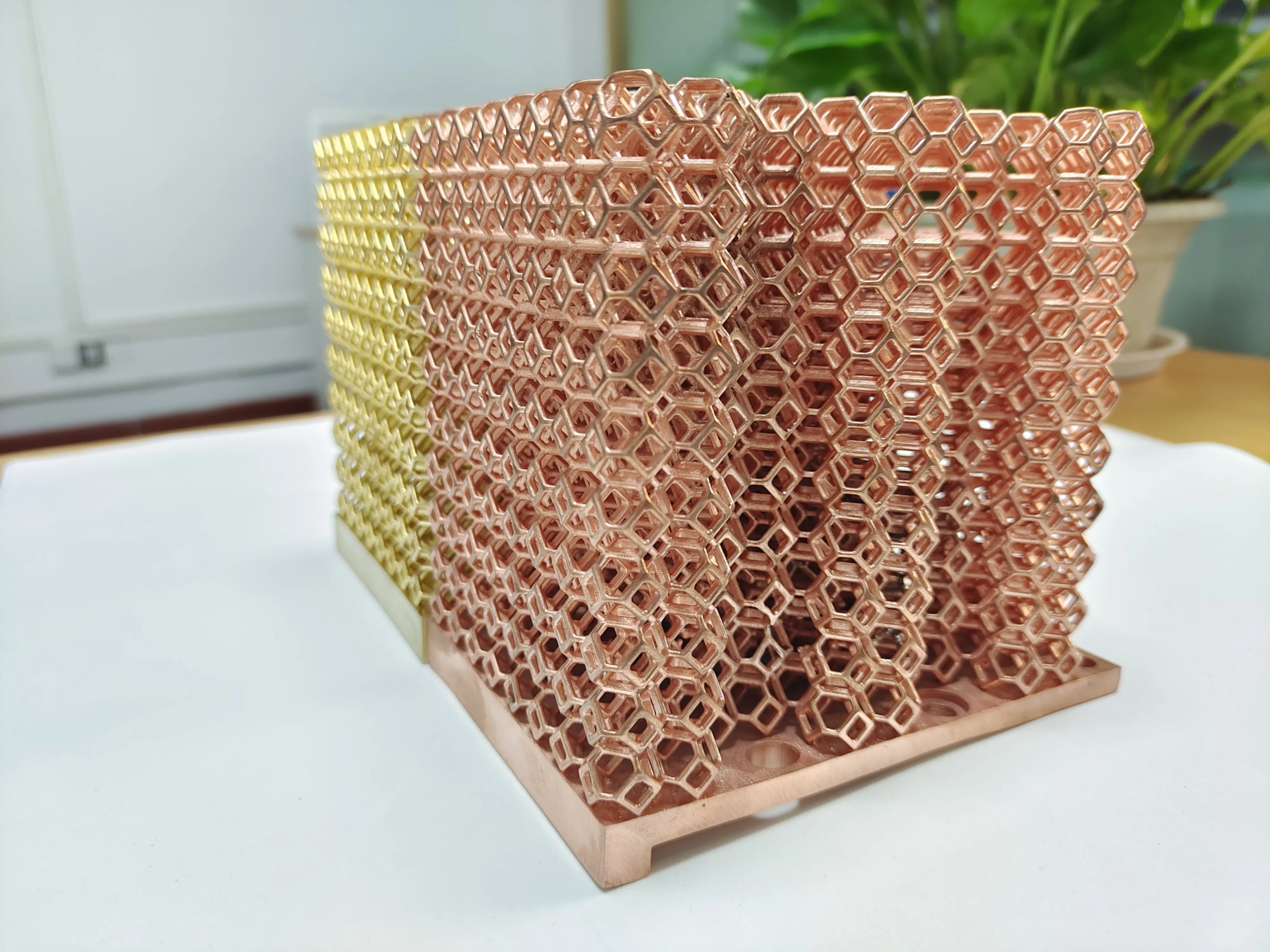

The concept of using 3D printing for egg storage includes creating custom containers or packaging materials that protect eggs from damage and maintain a consistent environment. This is especially useful for transporting eggs from a long distance or storing them for a long time. The use of 3D printing allows the creation of complex geometric shapes and custom designs that can be tailored to specific needs.

One of the key benefits of using 3D printing for egg storage is the ability to maintain consistent temperature and humidity levels. This can be achieved by designing containers with built-in insulation and ventilation systems. Furthermore, the use of 3D printing allows the creation of containers with specific structural properties such as shock absorption and vibration damping, which can help protect the eggs from damage during transportation.

Greatlight’s expertise in rapid prototyping and 3D printing makes it an ideal partner for businesses looking to develop custom egg storage solutions. The company’s advanced equipment and production technology enables rapid creation of complex geometric shapes and custom designs that can be tailored to specific needs. In addition, Greatlight’s one-stop post-processing and finishing services ensure that the final product meets the highest quality and accuracy.

3D printing for egg storage has the potential to completely change the way eggs are transported and stored. By providing a safe and consistent environment, 3D printed containers can help keep eggs fresh and quality, reduce waste and increase efficiency in supply chains.

In short, using 3D printing for egg storage is an innovative application that has the potential to change the way eggs are shipped and stored. With its advanced equipment and production technology, Greatlight has a good location to help businesses develop customized egg storage solutions that meet their specific needs. Whether used for transportation or storage, 3D printing technology can help keep eggs fresh and quality, reduce waste and increase efficiency in supply chains.

FAQ:

*What is 3D printing and how to use it for egg storage?

3D printing is a technology that creates three-dimensional objects from digital design. In the context of egg storage, 3D printing is used to create custom containers or packaging materials to protect eggs from damage and maintain a consistent environment.

*What are the benefits of using 3D printing for egg storage?

The benefits of using 3D printing for egg storage include the ability to maintain consistent temperature and humidity levels, protecting eggs from damage during transportation, and creating custom containers with specific structural properties.

* Can Greatlight help me develop custom egg storage solutions?

Yes, Greglight is a professional rapid prototyping manufacturer with advanced SLM 3D printer equipment and production technology. The company’s expertise in custom precision machining and one-stop post-processing and finishing services makes it an ideal partner for businesses looking to develop custom egg storage solutions.

* How does 3D printing technology improve the efficiency of egg storage?

3D printing technology can improve the efficiency of egg storage by providing a safe, consistent environment, reducing waste and increasing supply chain efficiency. By keeping eggs fresh and quality, 3D printed containers can help reduce the risk of damage and damage, saving costs and increasing profitability.

ISO 9001 Factory