The rise of 3D printed Frankenstein creations: Fusion and flexibility unleash innovation

Imagine dissecting your design vision, drawing inspiration from the ingenuity of nature, the wonders of mechanical engineering, and artistic expression, then seamlessly reassembling them into functional objects previously thought impossible. this is reality "3D printed Frankenstein creation" – Metaphor for the revolutionary ability to combine disparate geometries, materials and features into a unified prototype or end-use part using additive manufacturing. Unlike Mary Shelley’s tortured monsters, these creations symbolize engineering liberationaccelerating cross-industry innovation with unprecedented design freedom.

Beyond Science Fiction: What defines a modern Frankenstein creation?

The creation of “Frankenstein” took advantage of the core advantages of 3D printing:

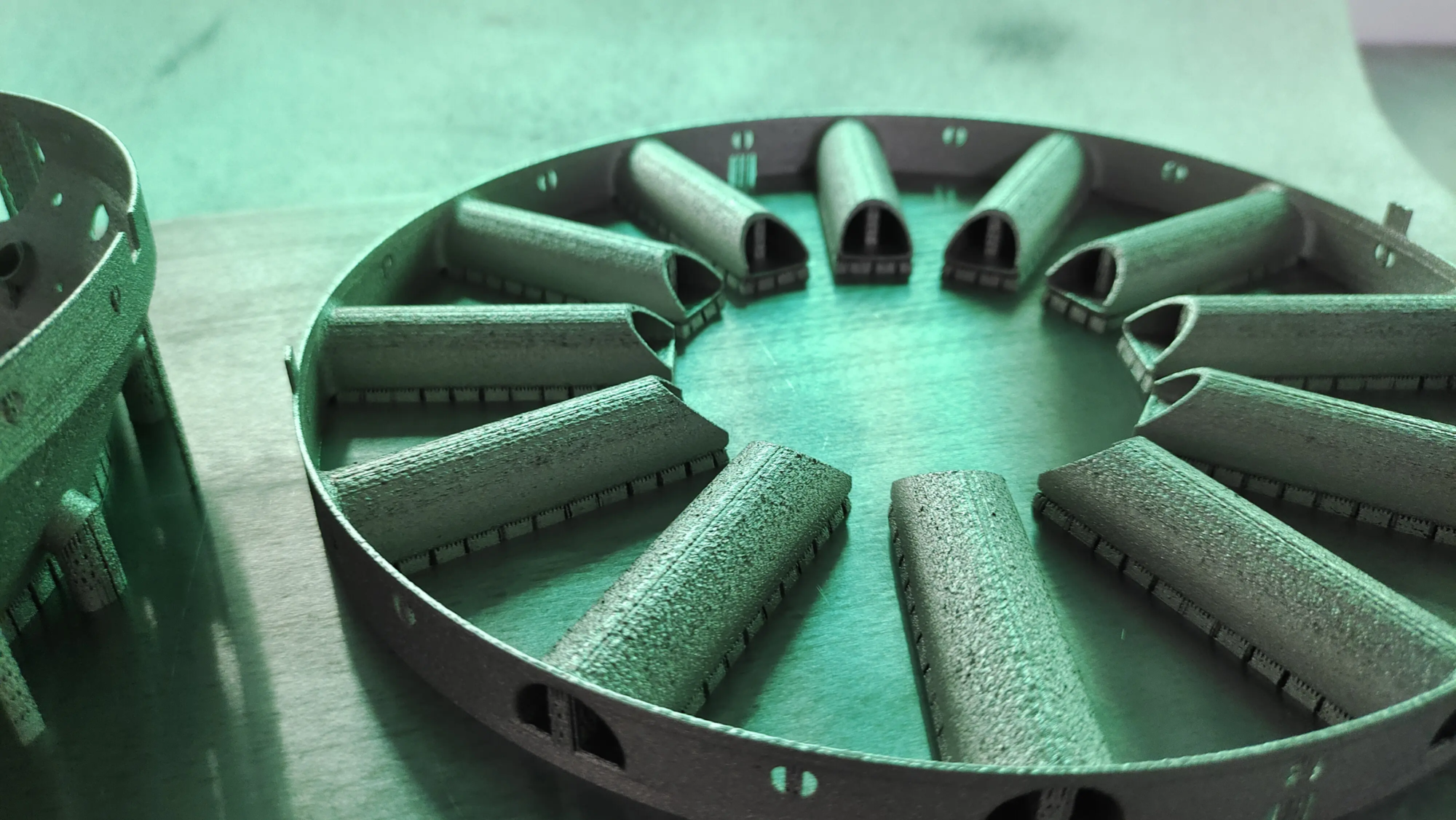

- Mixed geometry: Complex internal lattices from aerospace are combined with organic shapes inspired by coral reefs for lightweight biomedical implants.

- Material fusion: Thermoplastic elastomer (flexible seal) is printed together with high-strength metal (structural component) in one build.

- Functional integration: Sensors, electronics, fluid channels and moving components are integrated into a single printed part, eliminating assembly.

These creations are solving real-world problems

- Medical technology: Patient-specific implants combine porous titanium for osseointegration with a polymer portion for soft tissue compatibility. Surgical guide that combines MRI-derived anatomy with instrument holders.

- Robotics: Custom joints with embedded lubricated bushings are printed along with a lightweight exoskeleton frame that mimics bone structure.

- car: The engine components feature integrated conformal cooling channels next to the heat-resistant alloy combustion chamber.

- Art and Design: The sculpture blends reproductions of historical artifacts with generative structures driven by artificial intelligence, and is printed using resin-metal composite materials.

The technology that powers the modern Prometheus

create success "frankenstein" Rely on advanced hardware, materials and software:

- Multiple technology platforms: advanced SLM (Selective Laser Melting) Printers for aerospace-grade metals such as titanium or Inconel, paired with polymer printers (FDM, SLS) in hybrid workflows.

- Design software: Generative design tools (e.g., nTopology) use algorithms inspired by the principles of natural growth to optimize topology. DfAM (Design for Additive Manufacturing) ensures manufacturability.

- Materials Science: Support for specialty alloys, biocompatible resins, carbon fiber composites and ceramics enables functional combinations.

- Post-processing mastery: Critical finishing steps such as CNC machining for dimensional accuracy, heat treatment for stress relief, electropolishing or custom coatings for biocompatibility.

Overcoming Frankenstein’s Dilemma "monster" challenge

Complexity breeds potential pitfalls. Expertise can alleviate these problems:

- Geometric stress concentration: The fusion points between different geometries act as failure points. Solution: Finite element analysis (FEA) simulation preprint and iterative topology optimization.

- Material interface integrity: Different metals or polymers may delaminate. Solution: Precise printer calibration, custom support structures and interface engineering (graded materials, microstructure).

- Post-processing complexity: Different material properties complicate finishing. Solution: Proprietary methods developed through deep materials and process knowledge.

In this demanding orchestration process, a professional rapid prototyping partner becomes indispensable.

Working with Precision: The role of experts like GreatLight

Coping with these complexities requires more than just hardware; Deep application knowledgetechnical mastery, strict quality control. Companies utilizing Frankenstein creations turn to experts such as huge light. As a leader in the field of professional rapid prototyping, Honglite has:

- Cutting-edge SLM 3D printer: Enable high-precision, complex metal part manufacturing for demanding aerospace, automotive or medical applications.

- Comprehensive material library: Ability to source and process a wide range of metals, polymers and composite materials suitable for mixed functionality.

- Post-integration processing: Comprehensive finishing services – CNC machining, heat treatment, shot blasting, polishing, coating – ensure functional integrity and aesthetic perfection.

- Speed and customization: Fast iteration cycles (typically 1-3 days for metal prototypes) and flexibility for low-volume custom production runs.

For engineers and designers who push boundaries, GreatLight is both an enabler and a guardian of quality, transforming ambitious goals "frankenstein" Transform concepts into proven, practical realities under one roof.

Conclusion: The future is convergent

3D printed Frankenstein creations are nothing unusual; they represent the pinnacle of the design freedom unleashed by additive manufacturing. By fusing form, function, and materials previously considered incompatible, industries are solving problems considered unsolvable and creating products that were previously unimaginable. While the challenges of managing complexity are real, working with a professional rapid prototyping manufacturer like GreatLight can provide the technical sophistication and process mastery needed to successfully navigate these challenges. The days of constrained design are passing – usher in the age of smart, integrated and artfully blended creations.

Frequently Asked Questions About 3D Printed Frankenstein Creations and Rapid Prototyping

1. What exactly is "Frankenstein creation" In the field of 3D printing?

It refers to a functional part or prototype intentionally designed by the designer. fusion element Coming from vastly different sources – complex internal structures, multiple materials (metals + polymers) or integrated functionality (mechanical + electronics) – they are integrated into a unified part using advanced 3D printing technology.

2. Can any 3D printer print these complex hybrid parts?

Won’t. Simple desktop FDM printers lack the required precision, material range or thermal control. Creating a reliable Frankenstein build typically requires Industrial grade system like SLM metal printer and SLS/SLA polymer printers, as well as expert control of parameters and materials. Mixed parts from combined materials often need to be printed separately on separate machines and then professionally post-assembled/finished.

3. Is the Frankenstein creation suitable for end-use production, or just for prototyping?

Both! While valuable for rapid, iterative prototyping, many Frankenstein pieces designed through metal SLM printing achieve the strength, durability, and biocompatibility required for eventual aerospace, medical implant, or high-performance automotive applications. The lines between prototype and production are increasingly blurred.

4. How do professionals ensure the strength of materials? "fusion point"?

Expert partners use advanced technology:

- precise Finite Element Analysis (FEA) Simulation to predict stress points.

- intentional design Interface features (micro lattices, interlocking geometries).

- optimization Laser power/speed Gradient in material transformation.

- Post-printing processing such as HIP (hot isostatic pressing) to increase bonding density.

5. Why use a service provider like GreatLight instead of buying your own printer?

Frankenstein Project Requirements:

- High capital investment: Industrial SLM machines cost much more than desktop printers.

- Materials expertise: Purchasing, handling, and processing metal/biocompatible resins requires specialized facilities/knowledge.

- Post-processing infrastructure: CNC, EDM, advanced heat treatment, metallurgical laboratory testing.

- Mastery of process parameters: Ensuring repeatable quality requires in-depth experience.

Collaboration eliminates capital risk, accelerates schedules, and leverages expert results.

6. How to manage complex post-processing of multi-material parts?

This is core expertise. Strategies include:

- Carry out material-specific finishing steps in sequence (masking protected areas).

- Use non-contact methods (metal electropolishing, polymer vapor smoothing).

- Temperature controlled processing (annealing, HIP) is used.

- Combine automated CNC with skilled hand finishing to create sophisticated hybrid interfaces.

Explore fusion. Experience GreatLight’s expertise. Get ready to take your most complex, boundary-pushing designs from "frankenstein" Concept to functional masterpiece? Provided by Gretel End-to-end rapid prototyping powered by Advanced SLM technologytop-quality materials and integrated finishes – all customized to your unique requirements. Get precision fused parts faster at a competitive cost. Contact GreatLight today or Request an instant quote Unleash innovation without limit.