The concept of 3D printed air hoods has been fascinating in recent years, especially in the areas of rapid prototyping and manufacturing. With the development of 3D printing technology, sophisticated and customized air hoods can be created to provide greater protection and comfort to individuals working in hazardous environments.

One of the key benefits of 3D printing fuel masks is the ability to customize and suit individual users. Traditional gas masks usually have standard sizes, which can lead to poor fit and reduced efficiency. However, with 3D printing, gas masks can be created tailored to the specific dimensions and requirements of each user. This is especially important for individuals working in high-risk environments, such as firefighters, industrial workers or military personnel.

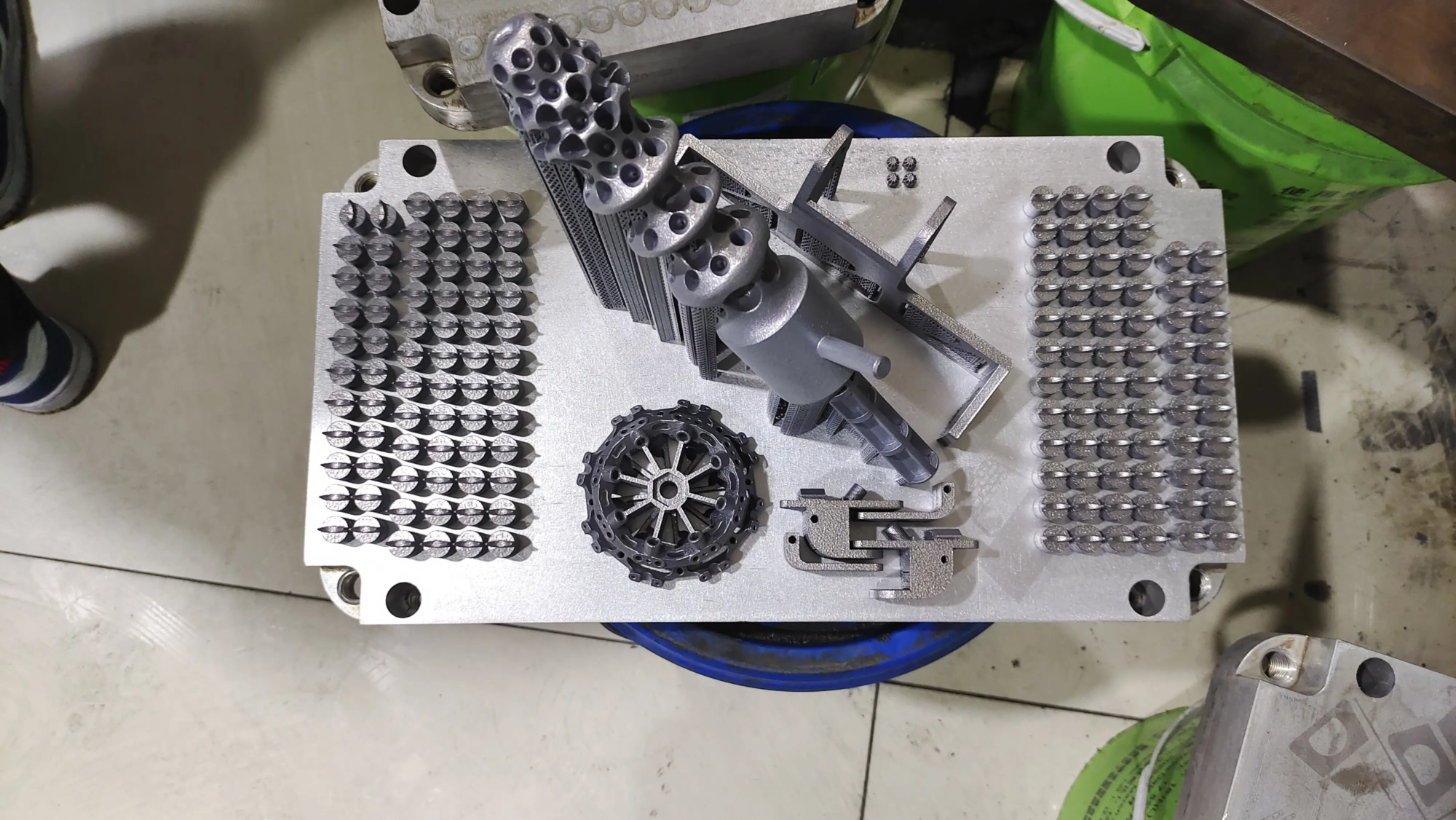

The use of 3D printing technology also allows the creation of complex geometric shapes and structures that cannot be produced using traditional manufacturing methods. For example, a 3D printed gas mask can have complex ventilation systems, advanced filtration mechanisms, and an ergonomic design that provides maximum comfort and protection. In addition, 3D printing can use a variety of materials, including plastics, metals and ceramics, which can be selected according to their specific characteristics and performance characteristics.

Greglight is a professional rapid prototyping manufacturer that has been at the forefront of 3D printing technology, leveraging advanced SLM 3D printers and production technologies to create high-quality metal parts and prototypes. With its expertise in rapid prototyping and manufacturing, Greatlight has a good location to offer customized 3D printed air hoods to meet the specific needs of individual users. Their one-stop post-processing and completion services also ensure that the final product is of the highest quality and meets the required standards.

The application of 3D printed air shields goes beyond the industrial and military environments and uses potential uses in medical, emergency response and environmental applications. For example, 3D printed gas masks can be used to protect health care workers from infectious diseases or to provide customized protection for emergency responders in dangerous environments. In addition, 3D printed gas masks can be used to develop new personal protective equipment (PPE) that is more effective, comfortable and sustainable.

In short, 3D printed air hoods represent significant advances in the fields of rapid prototyping and manufacturing. With the ability to provide customized fits, complex geometry and advanced materials, 3D printed air shields have the potential to revolutionize the way we approach personal protection equipment. As technology continues to evolve, we can expect to see new innovative applications of 3D printed gas masks in a wide range of industries and environments.

FAQ:

Q: What are the benefits of 3D printing of gas masks?

A: The benefits of 3D printed air hoods include custom fittings, complex geometry and advanced materials that can provide superior protection and comfort to individuals working in hazardous environments.

Q: Can 3D printed gas masks be used in industrial environments?

A: Yes, 3D printed gas masks can be used in industrial environments, such as in manufacturing, construction and oil and gas production, to provide workers with custom protection against hazardous air pollutants.

Q: How does a 3D printed gas mask compare to a traditional gas mask?

A: 3D printed gas masks offer a variety of advantages over traditional gas masks, including customized fittings, advanced materials and complex geometric shapes, which can provide superior protection and comfort.

Q: Can Greatlight provide customized 3D printed gas masks?

A: Yes, Greglight is a professional rapid prototyping manufacturer that can provide customized 3D printed gas masks using advanced SLM 3D printers and production technology to meet the specific needs of individual users.

Q: What are the potential applications of 3D printed air hoods?

A: Potential applications of 3D printed air hoods include industrial, military, medical, emergency response and environmental environments, in which case custom protection and advanced materials are required to protect individuals from hazardous air hazardous pollutants.

ISO 9001 Factory