Upgrade your roleplaying: 3D printed halo helmet thrills and challenges (plus when DIY meets Pro Power)

The iconic helmets of the Chiefs and the Spartans were more than just armor. They are symbols of courage, flexibility and advanced technology in the Halo Universe. For dedicated role-players and fans, making your own wearable legacy is the ultimate project. Moreover, more and more 3D printing has become the technology of choice to make dreams a reality. But how is this possible, and what role can professional services play in achieving a flawless combat look?

The charm of DIY 3D printed Spartan helmet

The DIY path provides great satisfaction. From purchasing documents to holding finished products, every step is learning to take risks. Here is a glimpse into the process:

- Hunting Model: It starts online. Famous platforms such as Thingiverse, Cults3D or specific creators Patreons (such as Galaxy Armory, Nerdforgegedesigns) can accommodate excellent Halo helmet models, from classic Mark VI to updated iterations. Ensure that the model is designed specifically for wearable capabilities (size, for filling/internal clearance of electronic devices, ventilation).

- Slicing legend: The 3D model file you selected (STL/OBJ) needs to be converted to printer instructions through slicing software (Cura, Prusaslicer). This stage is crucial:

- Size and Size: It is crucial to accurately scale the model to fit your head. Measure carefully! Consider adding 15-20mm of extra fill.

- support: The intricate sun visor, the bottom curve and details require intelligent support structure. Call these to prevent printing failures.

- Filling and walls: High wall counts and medium fillers (20-30%) provide strength without excessive weight or substance use. Too low, it will break; too high, it will be troublesome.

- Printing activities: This is the place to be patient. Printing a helmet-sized object is an important commitment:

- FDM (Filament): The most common DIY method. PLA is very popular; PETG is stronger and less brittle. ABS/ASA has higher temperature resistance, but requires housing and flue management. Looking forward to multiple works, A few days or even weeks Total printing time.

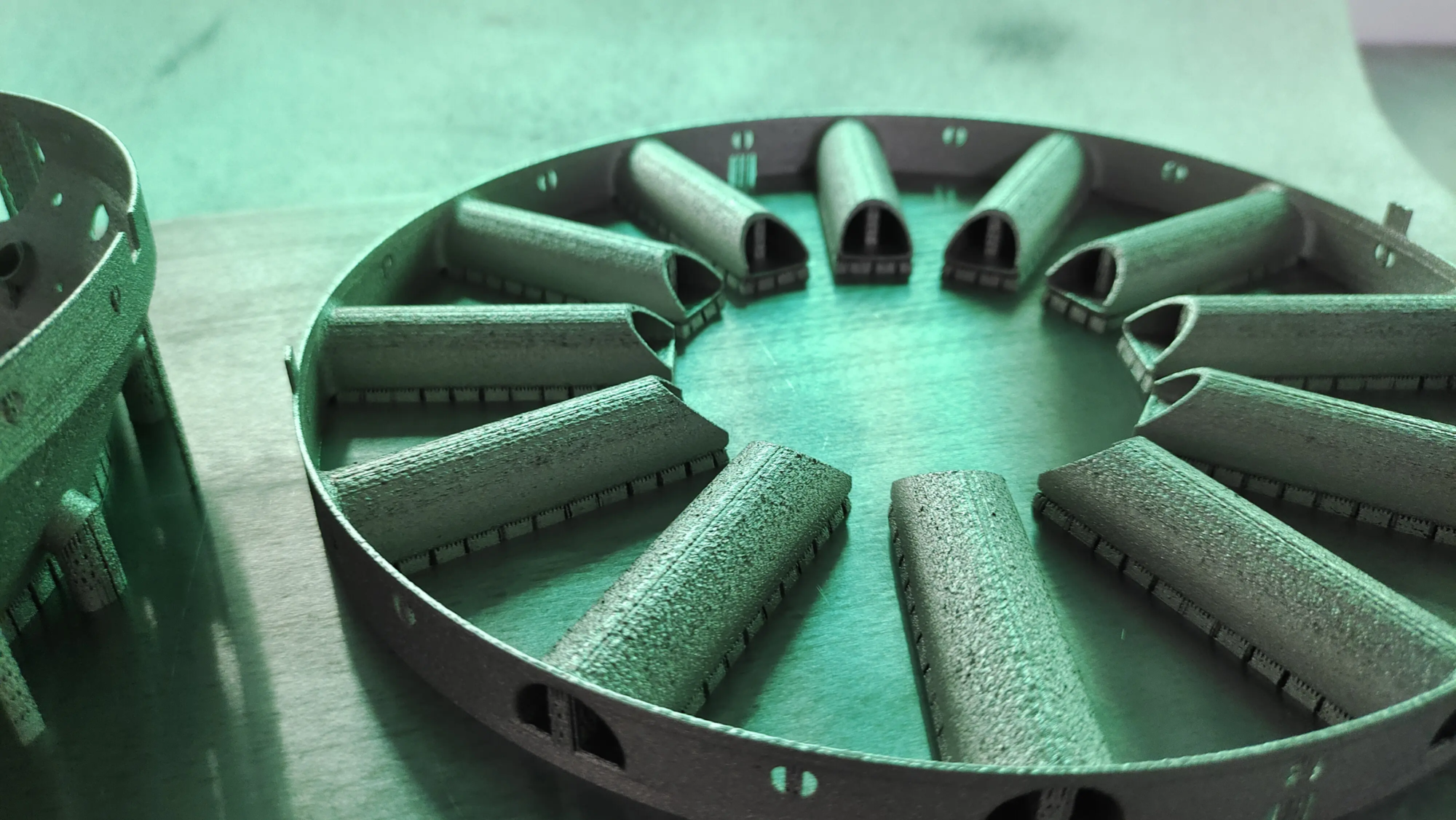

- Resin Printing: Provides incredible, ready-made surface quality and finer details. However, resin helmets require careful post-processing (washing, curing, possibly reinforced with fiberglass/epoxy) and are more brittle. The cost may be higher.

- Rally and Bonds: Multi-part printing requires careful bonding. PLA can be used well with super hair (CA) or epoxy resin. ABS requires ABS cement to perform real welding. Alignment is crucial to avoid skewed Spartans! Use a lot of fixtures and tape.

- Dirty job: Post-processing: Original printing is just the beginning. Prepare:

- Grinding: The hours start with coarse sand (80-120) to remove the layer lines through finer gravel (220, 400+).

- Fill and start: A filler primer spray helps reveal blemishes. Body filler (Bondo) solves larger gaps and seams. Repeated polishing cycles are your new normal.

- painting: Basic coat, detail painting, washing, dry brushing – technology supreme. The spray gun provides the smoothest effect.

- Sun visor: A sun visor formed from a vacuum of PETG or colored plastic is a complex skill. Many people choose prefabricated replacement motorcycle visors that fit.

- Filling and electronic: The foam filler is strategically installed inside for comfort and fit. LED, fans, voice regulators add finishing touch.

- Protective seal: Seal everything with a clear jacket to protect your superb paint job.

Reality and obstacles of DIY armor handmade

Although it makes a lot of sense, the DIY journey faces major challenges:

- Time Investing: This is not a weekend project. We are talking about for over 100 hours.

- Printing failed: Large, long prints are prone to bends, layers move, spaghetti mess or breaking support. Materials and power costs add up.

- Technical Skills Barriers: Mastering printing settings, resin handling, advanced polishing, bodywork and electronics requires practice and patience.

- Surface surface limitations: Achieve a truly smooth, professional finish, similar to molded prop armor, requires a huge skill and effort on FDM prints. Resin alleviates this, but increases concerns about worry.

- Durability issues: The PLA helmet bent in hot weather. PETG is elastic, but expensive for large parts. Even if the resin is not reinforced, the resin is fragile.

- Literally save lives: Safety: Proper ventilation of resin and grinding particles is not transportable.

Enter professional: When "Good enough" Not enough (and Greatlime’s come in)

This is a professional rapid prototype service like this Great Perspective narrative, especially when you seek ultimate quality, durability, or complications, and maybe even in metal.

- Possibilities beyond plastic:

- Metal Chief? use Selective laser melting (SLM) Technology, companies like Greatlight can produce helmets from lightweight, high-strength metals such as aluminum or titanium alloys. Think of incredible durability, heat resistance, exotic aesthetics (polished/polished metal finish!), and unparalleled structural integrity. Ideal for displaying works, custom commissions or shooting props.

- High resolution resin for display: Professional-grade stereolithography (SLA) machines produce exquisite details and finishes directly from the printer, minimizing the laborious post-processing of the display work.

- Solve complex problems: Can be specialized in producing precise joints for pronunciation, complex internal channels of wiring/cooling systems or highly complex FDM details.

- Material expertise: Using engineered grade polymers (nylon composites, Ultem-like resins) to enhance temperature/impactivity or specialized cast resins, goes beyond hobby materials.

- Process level surface: Professional post-processing functions, such as:

- Smooth/Polish: Consistent, highlight or matte finish.

- Dyeing/vibration finish of resin parts.

- Painting/Powder Coating: Showroom quality car finish (metal, candy, clear).

- Precise machining: for critical mounting points or interfaces.

- Time is precious: Letting professionals handle the production of parts or complex components allows you to focus on design, assembly, electronics and pleasure Part of the completion.

Greghime: Raise pole production with advanced rapid prototyping

exist Greatwe understand the passion behind projects, such as creating the iconic glow helmet. We combine the cutting edge SLM 3D Printing (Metal) and advanced polymer technology with decades of rapid prototyping expertise to solve complex production challenges. Whether you are:

- A fan of wanting Printing from complex high-tail helmets In the upper resin to perform the upper surface finish.

- Need one Mission-critical durable components (such as articulated hinge parts or visor mounts) printed on Engineering plastic or metal (via SLM).

- Commissioning truly unique Custom worksmaybe Critical internal functions or demanding material/strength requirements.

- need Professional post-processing service (Polishing, primer, painting, powder coating) to achieve museum quality results faster.

We provide:

- One-stop solution: From file optimization to final completion.

- High precision and speed: Quickly meet required tolerances.

- A wide selection of materials: Engineering plastics, high resolution resins and Metal alloy (using SLM).

- Expertise in the manufacturing of props and clothing parts: Understand fit, functional and aesthetic needs.

For the most challenging aspects of the Halo Helmet project, leveraging Pro Services is not "Cheating" – Strategically achieved results that exceeded the impact of most home settings. Design your ultimate helmet and let Greatlight solve the toughest production barriers professionally.

Conclusion: The Road to Becoming a Spartan

3D printing democratizes props, allowing fans to once retain the incredible halo helmet for Hollywood stores. The DIY road is difficult but profound and rewarding, and has honed valuable skills. Embrace challenges, polish, occasional failures – the feeling of finally wearing them your Creation is unparalleled.

However, recognizing that breaking the boundaries of details, durability, or materials requires professional tools and expertise. Here, working with rapid prototyping professionals such as Greatlight unlocks new possibilities. Whether it’s creating complex components in high-strength polymers, creating amazing metal fragments through SLM, or providing a perfect finishing touch, Pro Services allows you to effectively and sustainably achieve helmet perfection.

Ready to forge your legend? The cutting edge of DIY meets parental manufacturing.

FAQ: Your Halo Helmet Print Question Answer

Q: How much does it cost to 3D printing a halo helmet?

one: Costs vary greatly. DIY: Filament/Power ($40-$150+ Material, depending on material and failure rate). Resin substances are higher. Tools (sanders, fillers, sprays, paints, visors) are easily added to hundreds. Professional printing/basic decoration start Significantly higher ($200-$500+), but can save huge labor and tool costs, delivering excellent results faster. Due to the complexity of materials and processes, metals (SLMs) or complex professional prints will be more expensive.

Q: What is the best printer for a DIY Halo helmet?

one:

- FDM: Solid Corexy Machine (Rat Drill, Voron Built) or large bed printer (Creality CR-6 SE Max, Anycubic Kobra Max, Elegoo Neptune 4 Max) Handle sizes at reasonable cost at good speed/reliability.

- Resin: Large format MSLA printer (Elegoo Saturn series, Anycubic Photon M3 Max, Phrozen Sonic Mega 8K) Due to the size of the helmet, it is crucial. Remember ventilation and aftertreatment space!

Q: How to get the right size helmet?

one: Measure the circumference around the widest point of the head (eye, above the ear). Add at least 15-20mm of internal filling/clearing. Use the sizing tool in slicing software or consult the recommendations of the model designer. If you are not sure, print the test tape or small section first.

Q: How long does it take to print?

one: Expected 3-7+ days All Print time multi-piece build on FDM. Large resin buckets can print large sections faster, but post-processing curing, cleaning, etc. will increase time. Patience is not negotiable.

Q: PLA vs PETG vs abs/asa vs resin: What should I use?

- PLA: The simplest printing is only for decorative purposes. Easily twist in heat (for example, inside a car). Decent display, risk prolonging wear.

- PETG: Compared with PLA, resistance resistance, temperature resistance (~80°C), flexibility and layer adhesion. Excellent choice for wearable armor prints.

- ABS/ASA: Maximum temperature resistance (~100°C+), optimal chemical welding capability. Need a closed printer and good ventilation. Warpage is prone to occur without controlling heating. Excellent durability.

- Resin: Stunning details and finishes can be painted, but are crispy. Extensive aftertreatment, ventilation and usually internal reinforcement (fiber glass/resin coating) are required to be durable.

Q: When should I consider using a professional service like Greatlime?

one: Consider the following situations:

- you need to Extreme durability (For example, metal components through SLM or engineering plastic).

- You request one Perfect, smooth finish There were few months of polishing.

- Your design needs Complex internal functions, high precision or external materials Beyond amateur printers.

- You have Limited time But hope for top results.

- you need to Specific, complex post-processing (Polishing, powder coating, metal plating).

- The elements you want to print High strength metal For structural integrity or aesthetics.

Q: Can Greatlight print the entire helmet?

one: Yes, within the size limit, we can design sizes or complete helmets based on design sizes and selected techniques (large SLA/SLS for polymers, SLM for smaller integrated metal designs). We can also apply a wide range of applications. However, for practical reasons, most large props are designed as multi-part components. We can handle the entire production process.

Q: How do I start with Greatlight?

one: Visit our website! You can upload 3D model files, specify material requirements, complete preferences and request a quote. Our engineering team will review your project and provide expert feedback and cost/time estimates.