In recent years, significant progress has been made in the medical field, with 3D printing technology being one of the most famous innovations. One area where 3D printing shows great potential is the creation of custom implants, especially for knee replacement surgery. In this blog post, we will dig into the world of 3D printing knees and explore the benefits, technologies and future prospects of this revolutionary medical application.

Introduction to 3D Printing Knee

Traditional knee replacement surgery involves the use of standard, ready-made implants that may not exactly match the patient’s unique anatomy. This can lead to a range of complications, including loose implants, wear and reduced mobility. On the other hand, 3D printed knees offer a custom solution that can be tailored to the needs of the patient. By using advanced imaging techniques, such as MRI or CT scans, surgeons can create precise digital models of the patient’s knee joints and then use them to design and print custom implants.

Benefits of 3D printing knees

There are many benefits of 3D printing of knees. First, custom implants can improve fit and function, thereby reducing the risk of complications and allowing patients to recover faster. Additionally, 3D printed knees can be designed to retain more patients’ natural bones and tissue, which can help keep the knee joints natural movement and sensation. Furthermore, 3D printing technology allows the creation of complex geometric shapes and structures that cannot be produced using traditional manufacturing methods, enabling the development of innovative implant designs that can better mimic the natural anatomy of the knee.

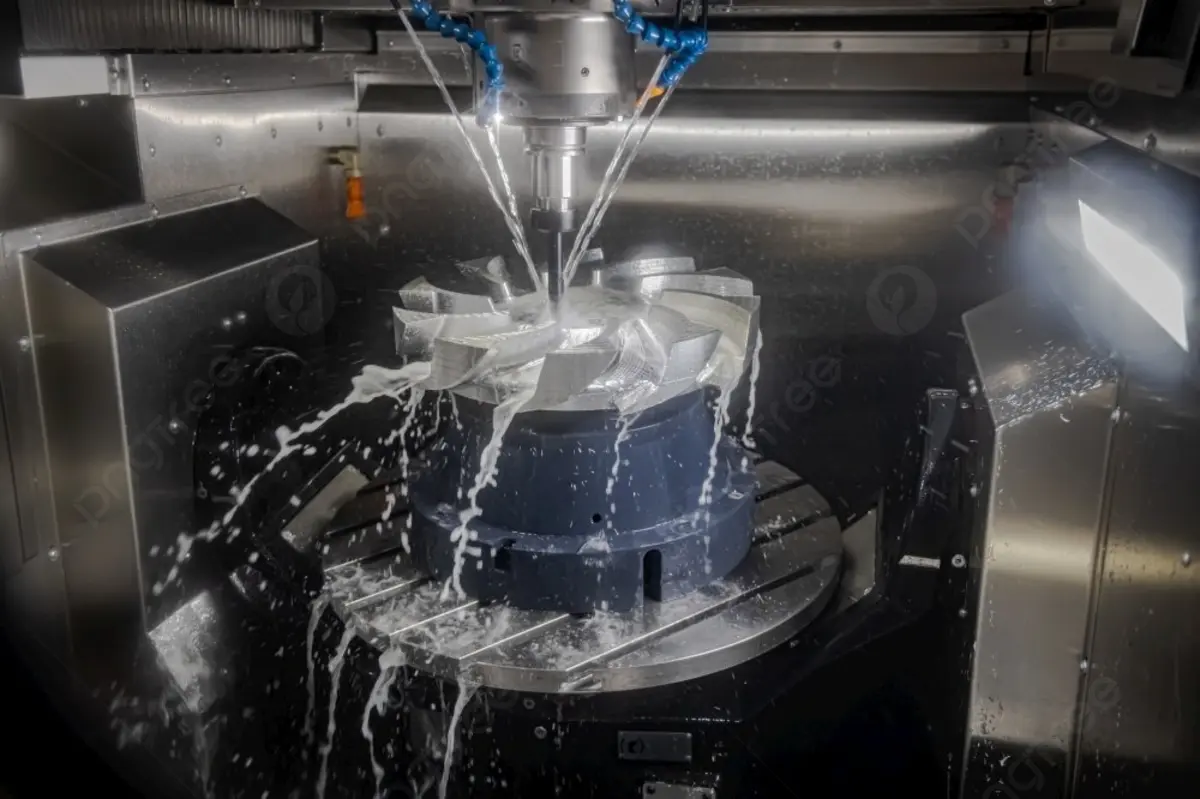

3D printing technology behind the knee

The technology behind 3D printing of knees is based on advanced additive manufacturing technologies such as selective laser melting (SLM) or electron beam melting (EBM). These processes involve a fusion of a layer of metal powder or other materials to create complex structures with high precision and accuracy. The use of SLM and EBM can produce implants with high strength, durability and biocompatibility, making them suitable for long-term use in the human body.

Post-processing and completion

After printing, the implant undergoes various post-treatment and finishing operations to ensure its surface quality, dimensional accuracy and biomechanical properties. This may include processing, polishing and surface treatment to improve the wear resistance and biocompatibility of the implant. Greglight is a professional rapid prototyping manufacturer that provides a one-stop after-processing and finishing service for 3D printed implants, including customized precision machining and surface treatment.

in conclusion

3D printed knees represent a significant advance in the field of orthopedic surgery, providing customized solutions that can improve patient outcomes and reduce complication risks. By using advanced imaging techniques, additive manufacturing techniques and post-processing operations, implants that are suitable for individual patient needs can now be created. As technology continues to evolve, we can expect to see further innovations in custom implants that allow patients to restore their mobility and quality of life.

FAQs (FAQs)

- How much does it cost to 3D print your knees?

The cost of 3D printing of knees may vary depending on the implant design, the materials used, and the complexity of the manufacturing process. However, with the widespread adoption of technology, it is expected that the cost of 3D printing knees will be reduced.

- How long does it take to design and print custom knee implants?

The design and printing process of custom knee implants can take several days to weeks, depending on the complexity of the design and the availability of the printing equipment.

- Is 3D printed knee approved for FDA?

Yes, several 3D printed knee implants have been approved for use in the United States by FDA. However, a qualified surgeon must be consulted to determine the best treatment for a specific condition.

- Can 3D printed knees be used for revision surgery?

Yes, 3D printed knees can be used for revision surgery, where previous implants have failed or need to be replaced. Customized implants can be designed to meet the specific needs of reforming surgery.

- What material is used to print 3D knees?

Materials used to print 3D knees include titanium alloys, cobalt-chromium alloys, and other biocompatible materials. The choice of materials depends on the specific requirements of the implant design and the needs of the patient.