Blog Post: The Final Guide to 3D Printing License Plate Framework

In an era of personalization and DIY innovation, 3D printing has reshaped how we handle everyday accessories (including automotive upgrades). Once purely functional, the license plate frame is now a canvas of creativity, branding and durability. In this guide, we will explore the ins and outs of 3D printed license plate frameworks that reveal their welfare, material choices, legal considerations and production workflows. Whether you are an auto lover or a manufacturer, this is your smarter, smoother customization blueprint.

Why 3D Print Your License Plate Frame?

1. Unparalleled customization

From complex patterns and logos to custom text or integrated lighting brackets, 3D printing converts a universal frame to a unique statement. Hobbyists use free CAD tools such as Tinkercad to design, while businesses work hard to brand promotions.

2. Lightweight and durable design

3D printing optimizes the use of materials. The frame can be designed using lattice structures to reduce weight without damaging strength, making it ideal for performance vehicles or environments prone to corrosion.

3. Fast iteration and cost-effectiveness

Traditional molds involve high upfront costs and lead times. Using 3D printing, the design was tested and iterated overnight. Adjusting digital files is cheaper than reinstalling molds.

4. Sustainability

Additive manufacturing can only minimize waste by using only the required materials. Biodegradable filaments (such as PLA) or recyclable metals further reduce environmental impacts.

Material selection: Plastics and metals

Plastic (FDM/SLS printing)

- PLA/ABS: Affordable versatility, but prone to UV degradation.

- Nylon (PA12): Flexible and impact-resistant, suitable for durable use.

- limitation: The plastic frame may twist at extreme temperatures or impacts and requires a protective coating.

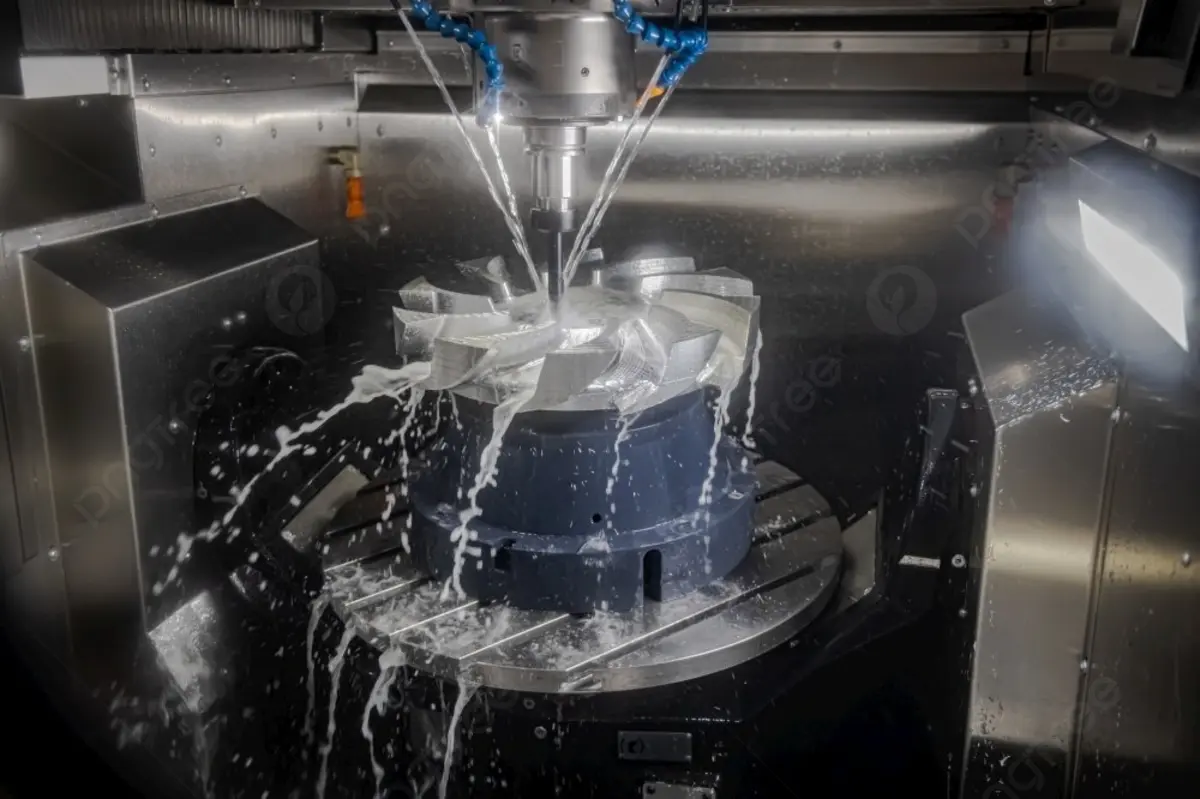

Metal (SLM/DML printing) ⭐ Greglight’s professionalism

Metal frames offer elite durability and high-quality results. use Selective laser melting (SLM)the printer fuses metal powder into a layer for unparalleled strength:

- aluminum: Lightweight and corrosion-resistant, it is ideal for automotive aesthetics.

- Stainless steel: Unrivaled resilience for harsh climates or elevated scenarios.

- titanium: Aviation-grade elasticity and minimum weight.

exist Great,We utilize advanced SLM/DMLS systems to deliver the ability of precise metal frames with complex geometries, i.e. plastics. Our process ensures zero porosity, high tensile strength and seamless post-processing.

Key Design and Legal Considerations

Durability first

- Insert reinforcement around the screw holes.

- Add chamfered edges to resist the impact.

- Optimize fill density (such as cellular structure) to balance weight/strength.

Compliance is important

License plate regulations vary by region. always:

- Avoid masking number of plates, status names, or registration tags.

- Ensure reflectivity standards are met (for example, no matte effect).

- Check the thickness of the frame or the local laws that highlight the elements.

Custom Pro Tips

- NFC chip embedded in digital vehicle profiles.

- Integrated sensor or camera mounting point.

- Automatically adjust global board size using parameter design.

3D Printing Workflow: From CAD to Installation

- design: Use CAD software (SolidWorks, Fusion 360) or work with the engineering team at Greatlight.

- simulation: Stress testing is performed with FEA software to identify weaknesses.

- Print: Plastic frames take hours; metal SLM printing usually takes 1-3 days.

- Post-processing: ⭐Greatlight’s expertise shines here:

- Metal finish: Bead blasting, polishing, powder coating or anodizing.

- plastic: Grind, epoxy smooth or steam smooth.

- Quality Control: Verify size, fastener alignment and complete uniformity.

Why metal frame? GREMIGHT EDGE

Although plastic is suitable for prototyping, Metal 3D printing frames dominate. They withstand road debris, temperature fluctuations and UV exposure compared to polymers. As China’s top rapid prototype partner, Great Combining these advantages with the following advantages:

- speed: 1-2 weeks leading time for end-use parts.

- End-to-end service: Design support, SLM/DMLS printing and professional finishes.

- Material versatility: Aluminum, steel, titanium and custom alloys.

Whether it’s prototypes for automotive customers or custom frames for performing cars, we’re not bent down – selling aerospace-grade quality at competitive prices.

in conclusion

3D printed license plate frames incorporate forms, functions and future ready manufacturing. For amateurs, they unlock unlimited creativity; for businesses, they are agile marketing tools. The shift to metal frames reflects the need for lifespan and advanced aesthetics, which cannot be achieved through conventional plastics. By working with experts GreatYou utilize industrial-grade SLM technology, simplified post-processing and engineering guidance – all under one roof. Use a fixed frame to enhance your car brand or personal ride.

Ready to customize? Explore Greatlight’s rapid prototyping solutions – your vision, accurate printing.

FAQ section

1. 3D printed license plate frame street – law?

Yes, if they comply with regional regulations. Avoid covering the details of the board or using prohibited reflective materials. Share your design with Greatlime – We will face the risk of conforming to the flag.

2. How long does 3D printed frame last?

- plastic: 1 – 3 years (weather dependent).

- Metal: More than 10 years (corrosion-resistant alloy).

3. Can I print multi-color or translucent frames?

Multicolor FDM printing is possible, but it is prone to layering defects. For translucent effects, use resin (SLA printing) or post-process dye on metal.

4. What is the cost difference between plastic and metal?

Plastic frames start at $5-$15/unit. Metal SLM printing ranges from $30-$100+, with design complexity and continuous changes in finishing.

5.

Absolutely. Our engineers optimize the design for printability, strength and hardware integration – powerless with prototype orders.

6. How to maintain metal frames?

Rinse with water; avoid rubbing the cleaner. Anodized/powder coated metal requires minimal maintenance.

7. Can I add electronics to the framework?

Yes! Greglight Embed LED mount, sensor housing and wire channels are printed using precise SLM.

8. What is the fastest turnover?

Rush plastic prototype: 1-2 days. Metal SLM: 3-5 days. Contact us for a 24-hour offer.

Upgrade your ride with aviation-grade craftsmanship. Customize your license plate frame now.