introduce

The Lombardy Trophy is awarded the Super Bowl Championship every year and is a symbol of excellence in professional football. Its stylish, spiral design and glittering metal finish make it a coveted icon. It is a dream for fans, collectors or event organizers to own a copy of this trophy, but the mass-produced version lacks the authenticity and personalization of many desires. Enter 3D printing: A revolutionary solution that enables accurate, customizable replicas with professional grade grades. This guide delves into the process of creating a 3D printed Lombardy trophy while highlighting such a way of advanced manufacturing services Great Offers unparalleled quality.

The charm of the 3D printed Lombardy trophy

Traditional trophys are cast from molds, limiting customization and accessibility. 3D printing bypasses these constraints:

- Personalization: Add team logo, print or tailored size.

- Accessibility: Create replicas for fans or events without permission barriers.

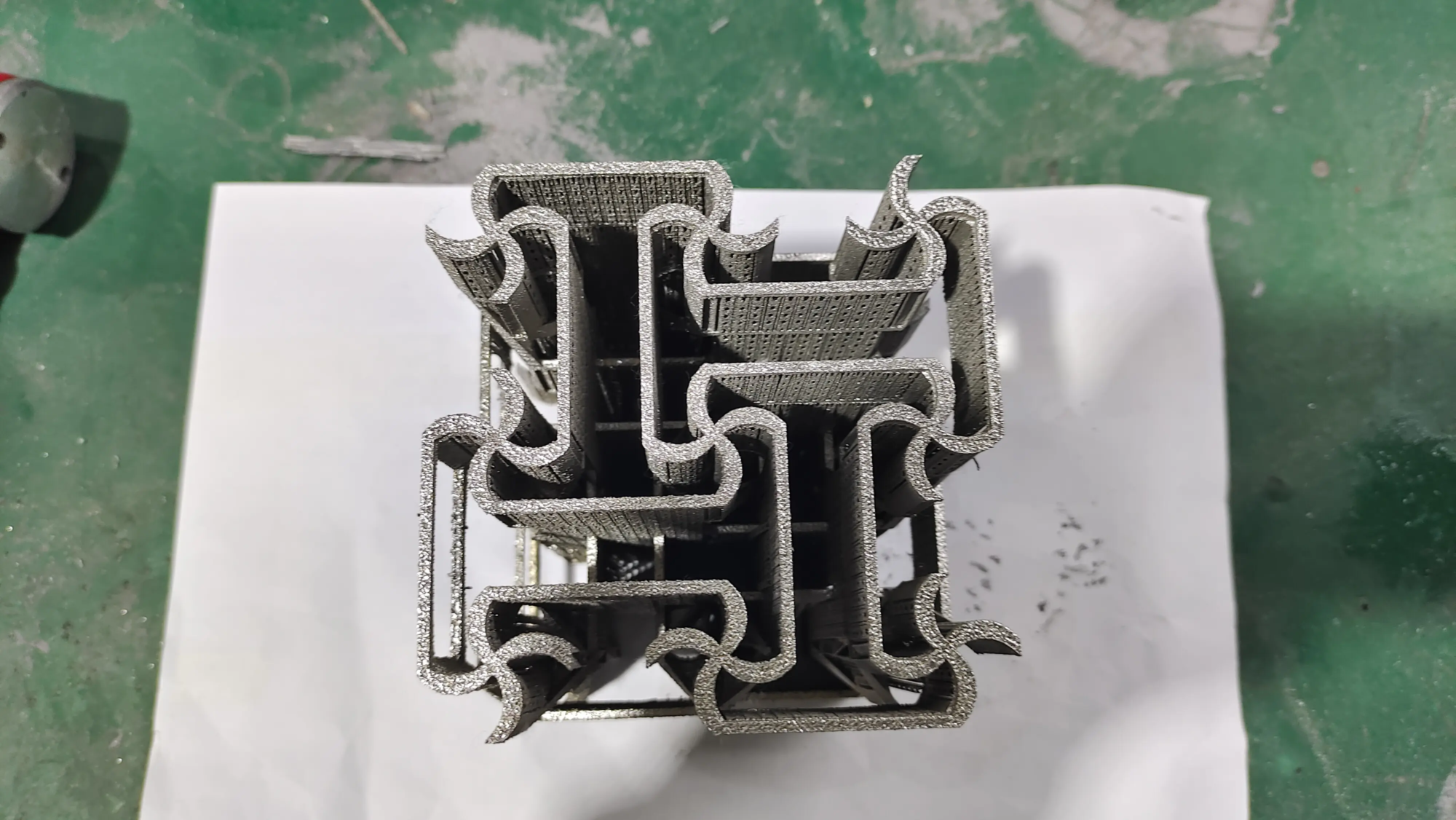

- complex: Captures intricate details of spiral spiral soccer base and surface texture.

However, the signature of Lombardy is realized Mirrored stainless steel appearance Demands professional equipment, materials and expertise – This is where industrial grade 3D printing flourishes.

Step-by-step guide to 3D printing trophy

1. Digital design collection

Start with an accurate 3D model. Since the official CAD file is not public, you have two options:

- 3D Scan: Use professional scanners on existing trophys (ensure copyright compliance).

- CAD Modeling: Skilled designers can recreate trophy using reference images from software such as Fusion360 or SolidWorks.

hint: Greatlight’s engineering team provides CAD redesign services to optimize your printing model.

2. Material selection

Authenticity depends on material choice. Common options include:

- Stainless steel (316L): Very suitable for metal trophy. Durable, corrosion-resistant, polished to high gloss.

- Titanium or aluminum: Lightweight alternative with high-quality aesthetics.

- Plastic/resin: For display-only replicas, despite the lack of metal realism, it is cost-effective.

Material selection affects the finish. Metal trophy needs SLM (Selective Laser Melting) Print structural integrity. For budget-friendly props, SLS nylon or SLA resin is enough.

3. 3D printing process

-

Metal printing:

- SLM technology: Laser fused metal powder layer by layer. This method ensures a dense, ineffective part essential for trophys with weight. Greatlight’s industrial SLM printers (e.g., the EOS M400) handle complex geometry without compromising details.

- Support structure: It is crucial for overhanging (for example, the curve of a football). These support must be removed manually later.

- Non-metal printing:

- SLA/SLS: Use photopolymer resin or nylon for complex surface textures.

- Post-processing: Add metallic gloss by metallization of electroplating or vacuum coating.

4. Post-processing: The key to realism

This stage converts the original print into an exhibition-ready trophy:

- Support deletion: The metal support is disengaged by CNC processing or wire EDM to obtain accuracy.

- Relieve stress: Heat treatment reduces residual stress in metal parts.

- Surface finish:

- polishing: Achieving the mirror finish of Lombardy through a grated belt, then manually.

- plating: Stainless steel trophy does not require plate plating, but plastic replicas benefit from nickel + chromium plating.

- Laser engraving: Add custom text or logo.

Greatlight’s one-stop service includes machining, heat treatment and custom plating – supply chain delays.

5. assembly

If in subdivisions (e.g., basic + soccer), weld or bond the parts. Final quality inspection ensures structural stability.

Why collaborate with Greatlight?

As a leader Rapid Prototyping ManufacturerGreatlight combines cutting-edge technology with expert craftsmanship:

- Advanced SLM printers: Produce dense high-resolution metal parts with precision <50μm.

- Material versatility: Stainless steel, titanium, inconel and custom alloys.

- End-to-end service: From CAD optimization to polishing and plated-all under one roof.

- Speed and scalability: Prototypes within 24-48 hours; mass production of events.

- Cost-efficiency: Competitive pricing through internal vertical integration.

Case study: A sports souvenir customer ordered 200 Lombardy replicas for company activities. Greglight offers SLM-printed 316-liter trophy in 10 days with mirror polish and custom foundation engraving.

in conclusion

3D printing allows people to access iconic symbols, such as the Lombardy Trophy, to blend art with engineering. While DIY attempts are often not about authenticity, industrial partners like Great Make sure the copy competes for the original. Their expertise SLM Metal Printing And integrated post-processing unlocks unprecedented quality, ideal for collectors, brands or commemorations. As additive manufacturing evolves, the boundaries between mass production and customization processes will continue to blur, making high-fidelity trophysical more accessible than ever.

FAQ

Q1: Can I legally print the Lombardy trophy?

A: Replicas for personal use or promotions are generally acceptable. However, selling brand trophys can infringe on NFL trademarks. Consult legal guidance for commercial projects.

Q2: How much does the 3D printed metal Lombardi trophy cost?

A: Cost varies by size, material and finish. The 10-inch 316-liter stainless steel trophy starts at about 300 – $500 (batch orders reduce per capita costs). Plastic replicas are priced under $100.

Q3: What is the delivery time for customized trophy?

Answer: Long-term: 3-5 days for prototype production; 10-15 days for polishing metal batches. An urgent option exists.

Question 4: Can I print the trophy in gold or silver?

Answer: Yes! Stainless steel can be plating with gold, silver or chrome. Alternatively, print directly with precious metal alloys (for example, injected with gold and copper).

Q5: How durable is 3D printed metal trophy?

A: SLM printed stainless steel matched force cast metal. They can resist corrosion, scratches and shocks – ideal for handling or display.

Q6: Which file format is well accepted?

a: .step, .obj or .stl. Their engineers will optimize your model when submitted for productivity.

Question 7: Do you provide color customization?

Answer: Yes! Options include anodized (aluminum), plating or enamel painting for logos.

Work with Greatlime

pass China’s major rapid prototyping experts. Specializing in precision metal printing and seamless post-processing, Greglight offers trophys that capture every curve and sparkle. [Contact us] Quotes today – Competitive pricing, minimum orders and global shipping.

Innovate confidently. Great Lights – Precision places will meet passion.