Revealing the Future of Secondary Exploration: The Rise of 3D Printed Manta

The elegant and undulating flight of Manta Ray through the depths of the ocean has attracted humanity for hundreds of years. This elegance is not only beautiful. This is a masterclass of effective advancement and mobility honed through evolution. Today, a fusion of advanced bioinspired design and cutting-edge Additive Manufacturing (AM)especially through services like this Greatis pushing this natural miracle to the forefront of the next generation of underwater robotics. Welcome to the world of 3D printing Manta Rays – Biobionics meet high-tech manufacturing to redefine underwater mobility.

Mastery of decoding Manta Ray

Manta rays achieve significant efficiency through unique anatomical features and movement:

- Buoyant wing-shaped body: Their broad pectoral fins work like wings, producing lift with minimal effort due to their hydrodynamic-optimized shape.

- Driving Wave Propulsion (TWP): Unlike the oscillating motion of a fish tail, mantas produces continuous fluctuating motion along the entire length of its pectoral fin. This produces smooth, thrust-efficient propulsion, and has low vortex and turbulence.

- Structural flexibility: The ceratotrichia in its pectoral fin is flexible, allowing the fin to bend optimally with each ups and downs, thus maximizing the thrust of each stroke.

- Low induced resistance: Large surface area and specific flexible patterns minimize the resistance usually associated with conventional propellers or slap foils, thus keeping it quiet and energy-efficient glides.

These principles translate into robots with superior capabilities: extended mission endurance, silent operation that is essential for observation or stealth, excellent low-speed maneuvers, and the ability to drive complex terrain or turbulence.

Manufacturing Revolution: Why 3D printing?

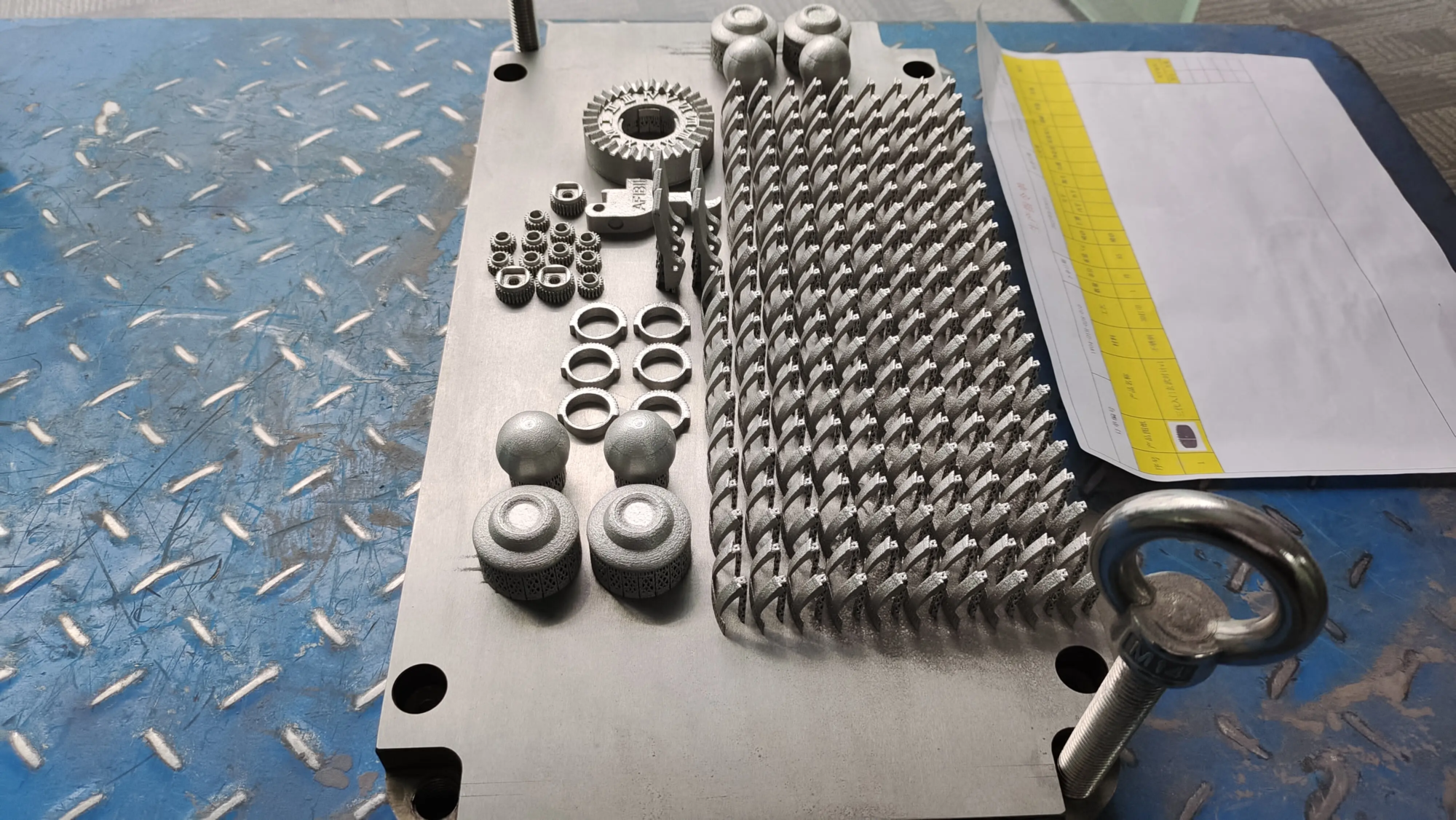

Reconstructing this complex biomechanical design presents a significant challenge to traditional manufacturing. This is Metal additive manufacturing (AM)especially Selective laser melting (SLM)becomes essential:

- Complex internal ecosystem: SLM is built layer by layer, thus creating internal channels for hydraulic, pneumatic, wire harness, electronic housing and buoyancy control systems – directly integrated into complex wing structures. Milling or casting simply cannot achieve this internal complexity.

- Organic tailored geometric shapes: AM can easily produce bionic curves and cavities essential for optimal fluid dynamics. In every aspect, the flap and reinforced ribs can be made into exact specifications. Advanced SLM features from Greglight Expert in achieving these complex near-mesh components.

- Lightweight power: Achieve high strength weight ratios is crucial for buoyancy control and efficiency. SLM allows topological optimization – the material can be strategically removed only without need to be maintained while maintaining structural integrity – creating ultra-lightweight but powerful internal lattices and bones that are not accessible by conventional methods.

- Material versatility: Underwater environments require corrosion resistance and durability. GreatExpertise covers a wide range of AM materials suitable for marine applications:

- Stainless steel (for example 316L): Excellent corrosion resistance in general salinity conditions.

- Titanium alloys (such as Ti6al4v): Excellent strength to weight ratio and excellent brine corrosion, ideal for critical structural components or deep-water diving variants.

- Aluminum alloy (e.g., Alsi10mg): Good strength and buoyancy, suitable for low-pressure applications where high pressure is required.

- Copper alloy (potential): For integrated electronic radiator or specific electrical needs.

- (Future Potential – Polymer): Although metal-dominated structural parts, advanced engineering polymers may be found in flexibility "skin" Elements or specific minor components generated through MJF, SLS or FDM – part of Greatlight One-stop post-processing and sorting service. The hydrophobic coating is printed after application and further improves performance.

- Rapid prototype and iteration: Testing the concept of fluid dynamics and propulsion requires multiple iterations. Greglight’s professional rapid prototyping solutions The design cycle has been dramatically accelerated. Functional metal prototypes with complex internal and external geometries can be quickly produced, allowing engineers to test, refine and optimize the design based on actual tank tests before making expensive tools. Rapid iteration is crucial to perfecting the nuances of Manta Ray movement.

3D Printing Metas’s pioneering application:

The potential impact of this technology is huge:

- Marine Science and Environmental Monitoring: These biological robots glide silently, which can monitor the health of coral reefs, map the seabed topography, track marine species (not let them be startled), collect water quality data (temperature, salinity, pollutants), and observe deep-sea ecosystems that are extended due to their efficiency.

- Underwater infrastructure inspection: Safely and accurately inspect submerged structures such as offshore oil rigs, bridge piles, pipes and underwater cables to damage or corrosion, eliminating the risks of human divers and the damage caused by noisy ROVs.

- Search and rescue operations: Effectively manipulated in complex debris fields or narrow spaces in shipwrecks or disaster areas, survivors or hazards may be found.

- National Defense and Security: The stealth function makes it a secret surveillance, a mine countermeasure in shallow waters, a countermeasure to the port protection patrol, and intelligence collection without acoustic signatures.

- Aquaculture monitoring: Monitor fish health and feeding methods, net integrity and environmental conditions within aquaculture pens without disturbing inventory.

Overcome design and manufacturing barriers

Designing functional 3D printed magat rays is complex:

- Fluid Structural Interactions (FSI): Accurately simulating how flexible printing structures interact dynamically with water flow is computationally intensive, but critical for predictive performance. Verification requires complex tank testing.

- Power system integration: Balancing the actuator power requirements (pneumatic systems, artificial muscles, motors) with battery weight/capacity and buoyancy is an ongoing challenge. Effective low twist, high-speed muscle actuators are key to mimic muscle function.

- Sealing and pressure management: Ensuring reliable waterproof seals (e.g., hydraulic shafts) and pressure housings for deep electronic devices is crucial. Greglight’s precise machining and completion capabilities It is crucial to achieve the required strict tolerances.

- Material fatigue and corrosion: Ensuring the long-term reliability of thin and flexible metal structures that experience cyclic loads in corrosive seawater requires careful material selection, design of fatigue and potentially protective coatings. Greglight’s knowledge of material properties and post-processing Mitigate these risks.

- Control algorithm: Mimicking the control complex, neural control of undulating wave motion requires real-time advanced AI controllers to process sensory feedback (pressure, flow, IMU data).

The future: Shooting towards innovation

Trajectories point to more complex trajectories:

- Advanced artificial muscles: Develop high-strength, effective electroactive polymer (EAP) or shape memory alloy (SMA) actuators embedded in printed structures.

- Enhanced Autonomy & AI: Intelligent robots can adapt their swimming gait to the current, cleverly surround obstacles, and even collaborate in groups.

- Comprehensive Sensor Kit: Direct integration of advanced sensors (chemical, biological, ultralight cameras, sonar arrays) during printing.

- Self-healing and morphological structure: Materials and design allow for minor damage repair or direct geometric adjustments for different tasks.

- Energy Harvest: Integrate the mechanism into harness waves or thermal energy for extended operations.

in conclusion

3D printed manta rays represent a paradigm shift in underwater robotics, surpassing the limitations of propellers and pipe propellers. By leveraging the genius of nature SLM 3D Printingengineers are developing machines with excellent efficiency, stealth and agility. Strong technical solutions are crucial to success. As a professional rapid prototyping manufacturer with advanced SLM 3D printers and deep expertise in post-processing, Greatlight has a unique position to provide essential rapid prototyping and customized precision machining services to pioneers in the field. Turning complex bioinspired designs into functional, durable marine-grade components requires Speed and accuracy. The silent sliding of Manta Ray is no longer just a miracle in the depths. This is a blueprint for quieter, more efficient, more insightful exploration of the ultimate boundaries of the planet, driven by the transformative power of advanced additives. Are you ready to drive your underwater innovation? Explore the Greatlight feature of your next project.

FAQ About 3D printed batta

Q1: Why do we need to imitate wheat field rays? Isn’t the fish tail faster?

A1: Although the fish tail can reach high speeds, Manta Ray propulsion has obvious advantages: Significantly higher efficiency To extend the cruising speed of the mission (week/month), Excellent low-speed maneuverability,,,,, Reduce noise generation For invisibility, and Intrinsic stability Because their wings are big. Their movement produces fewer destructive wake vortices than oscillating tails.

Q2: What are the main advantages of 3D printing (especially SLM) of these robots?

A2: There are several reasons why SLM shines:

- Complex internal channels: Creates an integrated path for hydraulic, wiring and buoyancy control within the wing structure itself.

- Lightweight: Enable topologically optimized lattices can reduce weight without sacrificing strength.

- Organic geometric manufacturing: Effectively construct complex curves that are crucial to fluid dynamic performance.

- Material selection: Use durable corrosion-resistant marine grade metals (stainless steel, titanium).

Question 3: What is the biggest technical challenge?

A3:

- Fluid structure interactive simulation: Accurately modeling how flexible printed fins deform and interact with water is a computational requirement.

- Electricity and Drive: Find lightweight, efficient actuators that can generate enough power/stroke for ups and downs while managing power consumption.

- Sealing and durability: Ensure reliable waterproof seals around moving parts and around long-term material properties under circulating loads in demanding seawater. Greglight’s precise post-processing It is crucial for sealing surfaces.

- Control complexity: Developing AI controllers is complex enough to manage complex fluctuating motions and adapt to various conditions.

Question 4: How important is the post-processing of these parts?

A4: Extremely important. Functional sanitary ray parts require:

- Surface finish: Smooth surface reduces resistance and prevents biological contamination. Complex interiors often require advanced technology.

- Hydrophobic coating: Reduce resistance and self-cleaning characteristics are necessary.

- Pressure relief/annealing: Eliminate residual stress during SLM and improve fatigue life. Greglight’s one-stop post-processing ensures that parts are ready.

- Precision machining: Sealing the surface on the housing flange, actuator interface, etc. is crucial.

Q5: Are there any real-world 3D printed sanitary ray prototypes today?

A5: Yes! Functional prototypes have been developed by universities (such as the University of Virginia, Peking University) and global research institutions, as well as companies specializing in bionic robotics. Many people utilize important metal 3D printing components integrated with flexible materials. These range from laboratory tanks to specific tasks in open water.

Question 6: How does Greatlight help bring my Manta Ray Design to reality?

A6: Grevermex is your premium manufacturing partner:

- Expert SLM production: Leverage our state-of-the-art printer and material knowledge Robust, complex marine-grade metal parts.

- Rapid Prototyping Service: Quickly Production of functional prototypes for testing Use our design concepts and fluid dynamics Excellent technology.

- Complex geometry mastery: Professionally solve the problem of rapid prototyping of metal parts Intrinsic in bioinspired design.

- Completed: One-stop post-processing and completion – Processing, surface smoothing, coating applications – Ensure performance and durability.

- Material guidance: Advice for the best Customized materials (SS, Ti, Al Alloys) Strength, weight and corrosion resistance requirements.

The potential of bioinspired underwater robotics has unlocked through expert rapid prototyping and manufacturing. Contact Greatlight today to explore how we can accelerate your project from concept to ocean deployment.