Forging Iconic Armor: A Journey to 3D Printing the Master Chief’s Helmet

Put on the Spartan Boots: For fans of the legend faint The Master Chief’s helmet is more than just a headgear; it’s a symbol of toughness, heroism, and sci-fi perfection. Recreating this iconic piece through 3D printing combines cutting-edge technology with passionate craftsmanship. At GreatLight, we see a growing demand for complex projects like this, pushing the boundaries of additive manufacturing. Whether for cosplay glory or display case prestige, crafting the Master Chief Helmet (Mark VI or later) is an exciting journey through design, materials science, and meticulous craftsmanship.

Why 3D printing embraces science fiction and fantasy

Traditional manufacturing methods struggled to cope with the helmet’s complex curves, multiple layers of detail and sheer scale. However, 3D printing thrives on complexity. Additive manufacturing transforms complex digital models into tangible reality, layer by layer, capturing the visor’s gaps, edges, and even subtle wear effects. Unlike mass-produced replicas, printed helmets offer unparalleled customization – scale for a perfect fit, add personal engravings, or try to mimic the materials of hardened Mjolnir armor.

Master the Blueprint: Design Matters

The journey begins in the digital realm. Finding accurate STL files is crucial – the fan community shares models from exact versions of games to stylized interpretations. Professional-grade design software such as Fusion 360 or Blender will typically optimize these files:

- Structural integrity: Add internal supports, optimize wall thickness, and design mounting points for sun visors or electronics.

- Printability: Orient the model to minimize support and prevent deformation. Helmets are often printed in multiple sections for use on larger format or desktop printers.

- Personalization: Modify features like chin vents or add shoulder armor integration attachment points.

Great Light Insight: For customers seeking custom designs, our engineering teams collaborate to optimize manufacturing files, using advanced topology optimization algorithms to ensure structural robustness and print efficiency.

Material selection: from PLA to metal alloys

The choice depends on features and budget:

- Polylactic acid/polyester: Easy to use, lightweight and easy to sand/paint – perfect for cosplay. PETG has better heat resistance.

- Resin (SLA/DLP): Capture microscopic details and achieve a museum-quality surface finish.

- Nylon (SLS): Durable, flexible and impact-resistant functional helmet.

- Metal (SLM): Gretel’s profession. Helmets forged from aluminum or titanium offer unparalleled density, heat resistance and a frighteningly authentic metallic sheen. Ideal for high-impact presentations or experimental feature pieces.

Overcoming Obstacles: Size, Details and Comfort

Printing helmets presents unique challenges:

- Warp and brace removal: Large prints face thermal stress. Strategic sectioning minimizes artifacts, while soluble support easily removes from complex sections.

- Sun visor integrated: Creating a nearly invisible installation for tinted visors requires precision. Vacuum forming is a common post-press processing.

- Wear resistance: Ergonomics are crucial for role playing. Internal padding, ventilation ducts and adjustable suspension systems are integrated during the design or finishing process.

The GreatLight Advantage: From Prototype to Perfection

This is where prototyping expertise shines. GreatLight addresses these complex issues head-on:

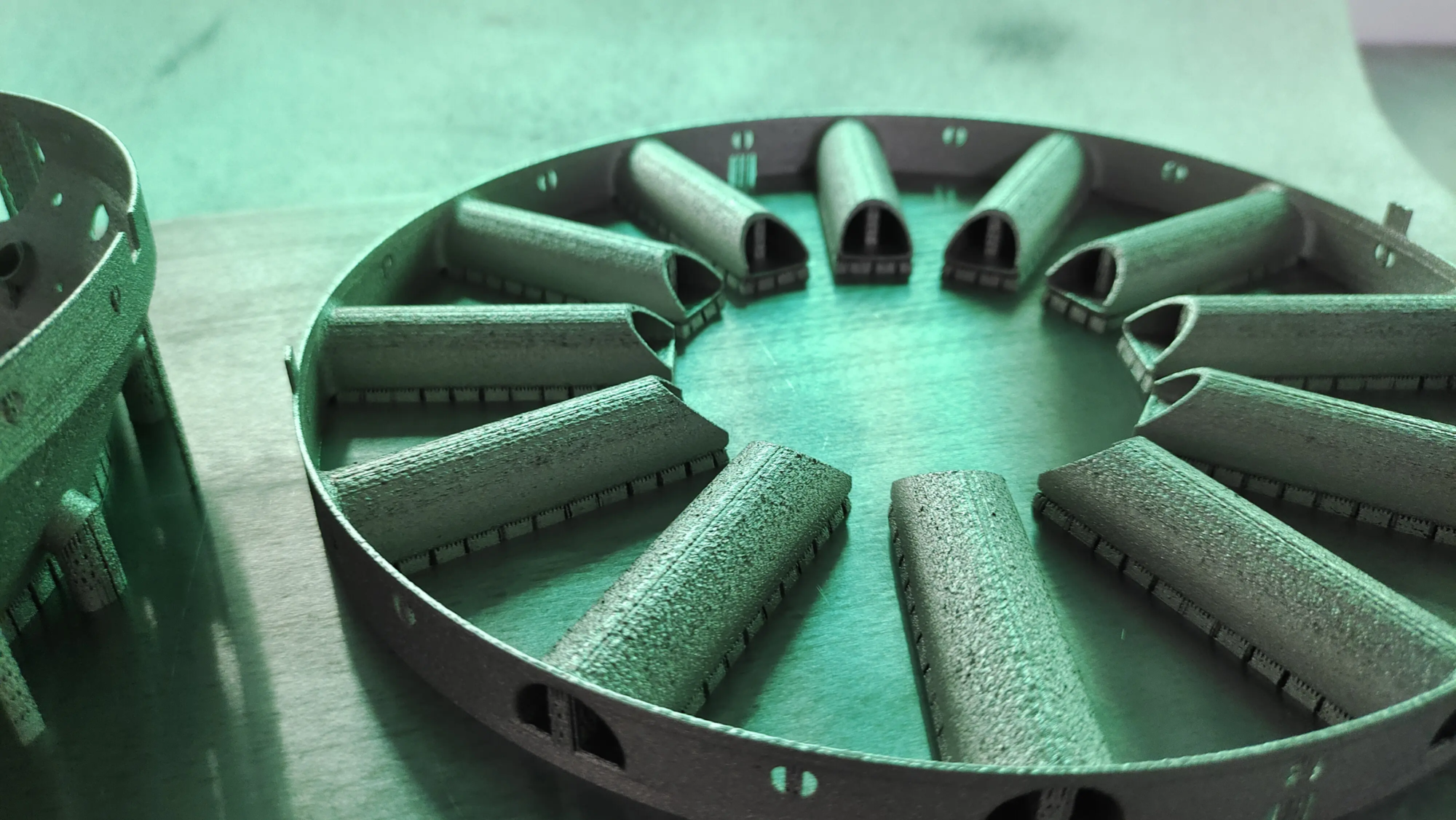

- Advanced SLM technology: For metal versions, our selective laser melting printer fuses titanium or aluminum powder layer by layer to create a dense, oven-ready helmet that’s comparable to forged metal.

-

Post-integration processing: We offer comprehensive finishing, which is essential for helmet manufacturing:

- Automatic support removal, sanding and polishing: Achieve seamless surfaces.

- Primer and Paint: Military-grade coating, weather-resistant effect or glossy metallic finish.

- Visor Manufacturing and Integration: Cut and mount acrylic or polycarbonate.

- Assembly and quality control: Assembly inspection and pressure testing.

- Fast material flexibility: Need lightweight nylon for comfort or ballistic stainless steel? We quickly customize material selections and scale prototypes without expensive tooling.

Crucially, our role extends beyond print: We work with designers to optimize models for manufacturability, anticipating structural weaknesses or printing artifacts before the build begins.

Conclusion: More than just armor – proof of innovation

Transform pixels into immersive artifacts by 3D printing the Master Chief’s helmet. This is a testament to the advancements in prototyping technology that allow enthusiasts and professionals alike to create the sci-fi fantasy that once was. At GreatLight, we recognize that these passion projects embody the spirit of innovation—requiring precision, mastery of materials, and ingenuity in problem solving. Whether you’re looking for a battle-hardened resin showpiece or a titanium-reinforced Titan ready for the most intense meetings on Earth, modern additive manufacturing (powered by expertise) is ready to build your creations faint heritage.

FAQ: Building Your Master Chief’s Helmet – Answered

Q1: Can GreatLight print full-size wearable helmets?

Absolutely! We specialize in large format printing using high strength materials such as PETG, nylon and even metal. We optimize designs for structural integrity and wear resistance, including practical considerations such as weight distribution and ventilation. For cosplay, we typically recommend printing and assembling in sections to enhance portability and accessibility.

Question 2: What is a typical timeline for this type of project?

The process from document preparation to delivery of the finished helmet varies:

- Design refinement: 1-3 days

- print: 2-7 days (depending on size, material and complexity)

- Post processing/finishing: 3-10 days (detailing, painting and visor integration)

It can be expected to take approximately 2-3 weeks total to create a detailed resin or plastic helmet. Metal helmets may take longer due to the sintering/curing stage and complex surface preparation.

Q3: How much does it cost? What affects price?

Cost factors include:

- Material: PLA < Resin ~ Nylon << Metal alloy.

- Print size: More materials = higher costs.

- Complexity/Support: Detailed grooves/supports increase printing time/resources.

- finishing: Basic sanding versus professional painting/weathering will add to the cost.

Basic PLA helmets start at about $300-$600. Highly detailed resin or metal helmets with professional finishes can cost upwards of $2,500. Requesting a personalized quote with design specifications will give you the most accurate estimate.

Q4: Can I provide my own STL file?

Yes! We welcome customer CAD files. Our engineering team reviews files for free for printability feedback – optimizing directions or recommending supports/pre-assembly. We ensure manufacturability matches your vision.

Q5: What paint/topcoat best handles vibration/wear?

For longevity we recommend:

- Primer designed for plastic/metal bonding. Epoxy primer provides excellent bonding.

- High quality automotive acrylic urethane paint with clear coat (matte/satin/gloss). Flexible additives are added to minimize cracking. Advanced hydrographic painting can distinguish complex patterns.

Q6: Is the wiring built into the helmet?

We integrated electronics ducting internally during the print process – ample routing for cooling fans (critical for long-term wear and tear), LED lighting channels, microphone/speakers, battery compartment – avoiding unsightly post-build additions. Our holistic design/production approach elegantly enhances functionality.

Q7: How durable is the metal printed helmet?

SLM helmets offer exceptional longevity – titanium’s tensile strength is close to that of its cast counterparts. They handle impact and weathering more reliably than plastic/resin alternatives. Although expensive, metal transcends into decorative showpieces to become highly functional heirlooms that protect investments.

Ready to be inspired? At GreatLight—one of China’s premier rapid prototyping innovators—we help dreamers quickly realize their bold visions. Transform raw prints into coveted works of art with our SLM/SLA/SLS platform and meticulous processing services. Submit your helmet design today to receive a rapid prototyping quote tailored specifically to armor-grade needs. Build beyond boundaries.