Rolling the future: Why 3D printing is revolutionizing mechanical dice

Imagine the satisfying clatter of dice on a gaming table—now imagine it being amplified by complex internal mechanisms to ensure perfect randomness. Mechanical dice improve functionality and aesthetics with their moving weights or bearings. 3D printing, especially metal additive manufacturing, has transformed this concept from a niche idea to an achievable reality. As a pioneer in rapid prototyping, GreatLight utilizes advanced technology Selective Laser Melting (SLM) Technology allows for precise custom dice sets that transcend traditional manufacturing limitations.

Design: a marriage of engineering and imagination

Making functional mechanical dice starts with careful design. Unlike static plastic dice, these dice have hollow cavities and freely movable components (such as common ball bearings or moving weights) to ensure unbiased rolling. Using CAD software such as Fusion 360 or SolidWorks, designers must:

- Optimize internal geometry: Make sure moving parts don’t get stuck and rotate freely.

- Calibration tolerance: Consider thermal expansion and material behavior during printing. The gap between moving parts is typically 0.1–0.3 mm.

- equilibrium density: Weight distribution affects scrolling behavior. For example, the stainless steel interior is paired with a titanium shell to fine-tune the weight.

GreatLight’ tear="Engineers work closely with customers to refine designs and address challenges such as support structure placement or heat dissipation before printing begins.

Material Selection: Metal Unparalleled Edge

Plastic 3D printing lacks the durability and tactile sophistication required of mechanical dice. Metal has clear advantages:

|Materials|Benefits|Use cases|

|—————-|———————————-|Forgot———————————- imports |

| Stainless steel |High strength, corrosion-resistant |Durable dice for frequent use |

| titanium |Lightweight, premium biocompatibility|Deluxe package; reduces desk noise |

| aluminum | Cost-effective, fast printing | Prototyping or building on a budget |

Why choose sustainable land management? GreatLight’s SLM printer fuses metal powder with a laser with micron precision. This ensures:

- Complex internal channels are not possible with CNC or injection molding.

- Isotropic Strength → The dice can withstand impact without breaking.

- Material diversity: from tool steel to copper alloys.

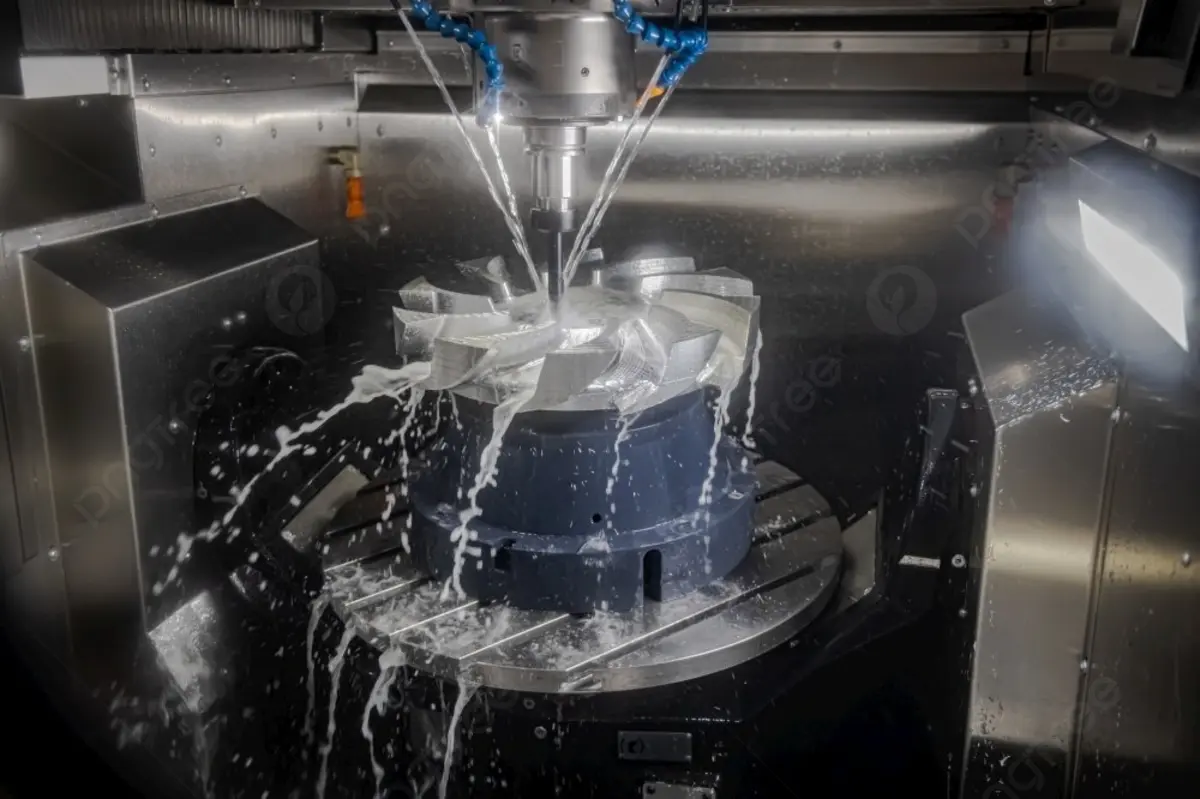

SLM printing process: precise layer by layer

GreatLight uses industrial SLM systems to execute projects:

- Document preparation: The CAD model is sliced into layers (20-50 microns thick).

- print: A laser selectively melts metal powder in an inert argon atmosphere to build the dice layer by layer.

- In-process monitoring: The sensor detects thermal inconsistency and ensures dimensional accuracy (±0.05mm).

Improved post-processing

The original print has residual powder and a rough surface. Gretel’s one-stop services include:

- Remove support: Ultrasonic cleaning can dissolve scaffolding.

- surface strengthening: Steam polishing for mirror effect, sandblasting for matte texture.

- heat treatment: Eliminate internal stress and achieve long-term structural integrity.

For dice, finishing is crucial – a perfect surface