Unleashing possibilities with 3D printing: Creating an iconic millennium puzzle

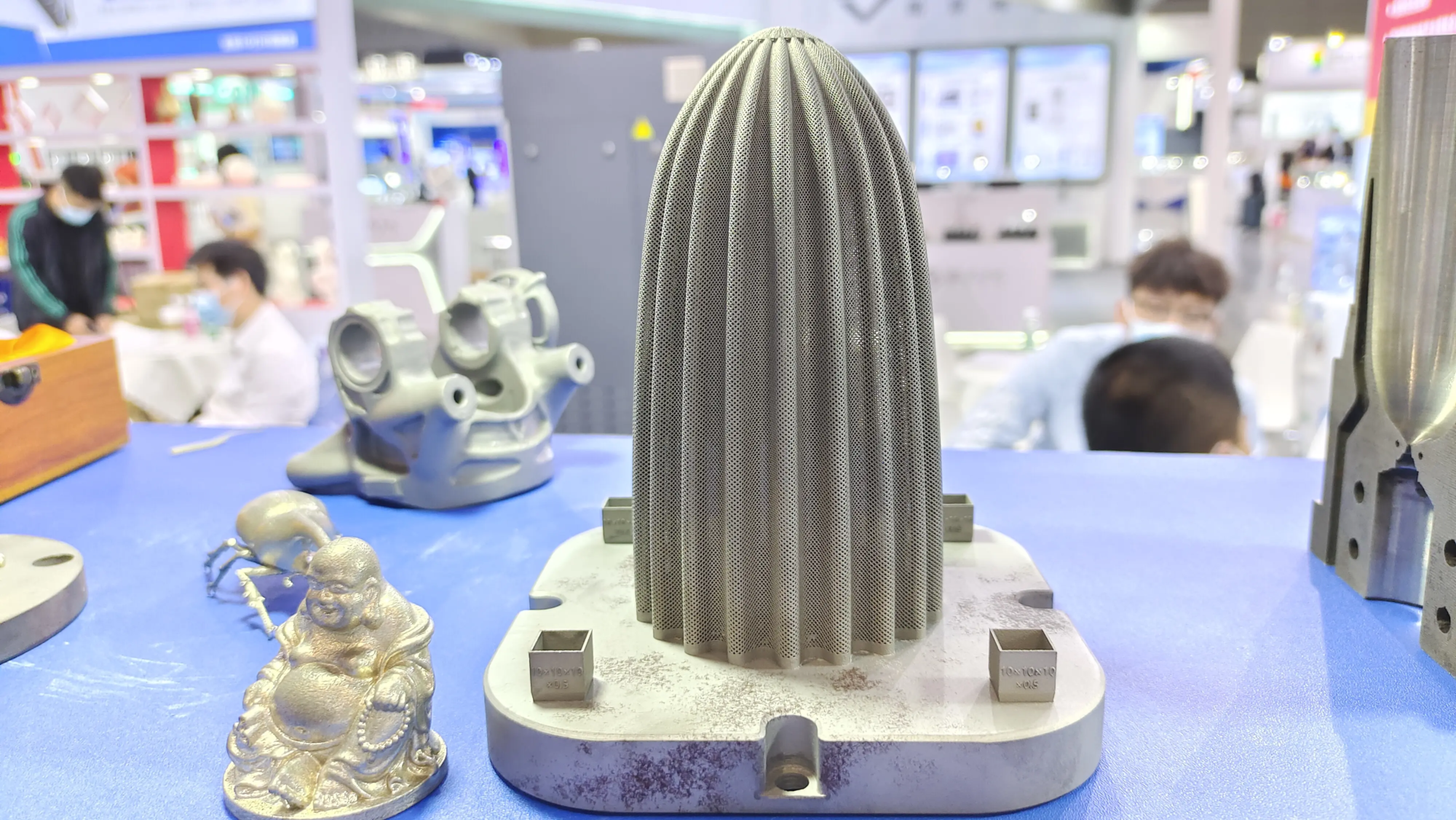

For fans of the legend You-ji-oh! series, the Millennium Puzzle is more than just an artifact; it’s also a work of art. It is a symbol of adventure, challenge and ancient mystery. Recreating this intricate, interlocking symbol once used by the pharaoh Atem is no easy task. Its complex geometry, precise tolerances, and smooth, gold-like finish require exceptional manufacturing skills. This is where the power of modern 3D printing comes into play, transforming digital designs into tangible, stunning objects. At GreatLight, we specialize in bringing these ambitious projects to reality using: Advanced selective laser melting (SLM) technology and meticulous post-processing.

Why 3D print the Millennium Puzzle?

Traditional manufacturing methods such as CNC machining or casting struggle with the internal cavities, sharp corners, and interlocking parts of puzzle pieces. 3D printing, especially metal SLM, has unique advantages:

- Geometric degrees of freedom: SLM builds the object layer by layer from powdered metal, allowing the creation of Puzzle’s complex internal structures and overhang features that would be impossible with subtractive methods.

- Precision and detail: High-resolution SLM printers capture the complex hieroglyphs and sharp edges synonymous with puzzle pieces, ensuring screen-accurate fidelity.

- Material Versatility: Choose sturdy metals like stainless steel, aluminum, or even titanium to create a true heirloom-quality replica with significant weight and feel.

- custom made: Want a larger version? Personalized engraving? Unique plating? 3D printing allows for complete customization that goes far beyond an off-the-shelf replica.

The Great Light Process: From Digital Blueprint to Legendary Artifact

Creating the perfect replica of the Millennium Puzzle is a multi-stage journey, requiring expertise at each step:

-

Expert design optimization:

- Our engineering team starts with an accurate 3D model. We analyze printability geometries and identify areas that require support structures during the printing process.

- Tolerance engineering is critical. Each part must fit together smoothly and securely – we carefully adjust gaps to account for material shrinkage and post-processing.

-

Advanced SLM Metal Printing:

- GreatLight uses state-of-the-art industrial SLM printers. A high-power laser precisely fuses fine metal powders (stainless steel 316L is popular for its strength and polishability) layer by layer according to a digital design.

- SLM’s ability to handle complex internal geometries makes it a perfect fit for Puzzle’s unique locking mechanisms and hollow sections.

- Our strict process controls ensure consistent density and minimize internal stress to ensure dimensional accuracy.

- Comprehensive post-processing – "aurora finish": This is where the magic happens, transforming original printed parts into museum-quality pieces:

- Support removal: Cleverly remove necessary support structures without damaging intricate features.

- Precision machining: CNC machining can be used at specific critical interfaces to achieve an ultra-precise fit between puzzle pieces.

- Surface perfection: Multi-stage process:

- Sand roughly to remove layer lines and support marks.

- Progressive fine sanding and polishing for a mirror-like finish.

- Vibratory tumble provides uniform smoothness, especially in hard-to-reach areas.

- Premium Finish:

- plating: Available in solid gold, rose gold or nickel plating for a signature look and feel.

- Painting and coating: Premium enamel or PVD coating provides long-lasting color and protection.

- Bronze/Antique: For those who crave the beauty of ancient, weathered artifacts.

Overcoming Challenges: Where Precision Meets Art

Bringing millennium-old problems to life with metals presents specific obstacles that GreatLight excels at overcoming:

- Interlocking accuracy: Achieving a perfect friction fit between the pieces requires exceptional dimensional accuracy throughout the printing and post-processing process. Our process controls ensure consistent results.

- Surface perfection: Eliminating 3D printed layer lines on complex curved surfaces requires skilled hand finishing techniques that we have perfected on countless projects.

- Structural integrity: Metal selection and printing parameters are optimized to ensure the puzzle is strong enough for handling and assembly, not just display.

- aesthetics: Matching the signature golden sheen requires expert plating and polishing knowledge – a core benefit of our one-stop-shop service.

Why partner with GreatLight on your Millennium Puzzle project?

as a leading China’s rapid prototyping and precision manufacturing expertGreatLight isn’t just about machines; proficient:

- Cutting-edge SLM technology: Our advanced printers guarantee the complex geometries and precision required.

- End-to-end expertise: From CAD optimization and material science to the most demanding finishing techniques (machining, polishing, electroplating), we handle it all from a single source.

- Unparalleled quality control: Each stage is rigorously inspected to ensure your puzzle meets the highest standards of accuracy, finish and functionality.

- Speed and scalability: Need a perfect prototype or a small batch? Our rapid prototyping ethos delivers quality without compromising lead times.

- Material Versatility: In addition to metal, we also offer high-resolution plastic prints (such as SLS or resin) in lightweight or color versions.

Conclusion: Embracing the Power of Advanced Manufacturing

The Millennium Mystery represents the challenge of turning fantasy into reality. 3D printing, and specifically GreatLight’s SLM capabilities coupled with our comprehensive finishing services, provide the key. We transform complex digital designs into stunning tangible objects with the precision, durability and aesthetic appeal worthy of such an iconic symbol. Whether it’s for cosplay, collectibles, engineering explorations or unique gifts, 3D printing bridges imagination and reality.

Are you ready to take the power of Pharaoh into your hands? For such a complex piece, don’t compromise on quality. Leverage GreatLight’s expertise One of China’s premier rapid prototyping partners. Contact us today for a consultation and quote on your custom Millennium Puzzle or any other complex metal fabrication project. Experience differentiated precision engineering and expert finish manufacturing.

Frequently Asked Questions (FAQ) – 3D Printing Millennium Puzzle

-

Q: What metals can you use to 3D print the Millennium Puzzle?

A: We mainly use stainless steel 316L because it has excellent strength, corrosion resistance and polishability, providing a near-perfect base for gold plating. Aluminum alloys (lightweight) and titanium (high strength, unique finishes) are also popular choices. Discuss your requirements with us!

-

Q: How durable are metal 3D printed puzzles? Can I really assemble/disassemble it?

Answer: Of course. Our SLM process combined with appropriate material selection creates highly robust parts. Post-processing ensures smooth mating surfaces. Properly designed and printed metal puzzles are very durable and can be handled and assembled over and over again, just make sure you don’t force the pieces together.

-

Q: How long does it take to 3D print and complete the Millennium Puzzle?

A: It depends on the size, complexity, material and finish chosen. Printing a standard size core structure may take 1-2 days. this crucial Due to the meticulous hand work and process steps involved, post-processing (support removal, machining, polishing, plating) often adds significant time – often 1-2 weeks or more for top finishes. We provide accurate timelines when quoting.

-

Q: How much does it cost to customize a metal 3D printed Millennium Puzzle?

A: Price depends on size, material selection (steel vs. titanium), complexity and especially Required level of finish (simple polish vs. full gold plating). Simple stainless steel models start in the hundreds of dollars, while larger titanium-plated pieces cost significantly more. Please contact us with your specifications for an accurate quote.

-

Q: Can you paint the puzzle instead of plating it?

Answer: Yes! While electroplating brings a true metallic look, we also offer high-quality painting services. We can achieve a smooth, durable finish in any color using advanced techniques like spray painting with automotive grade paint or PVD coating options.

-

Q: Do I need to provide a 3D model? Or can GreatLight create it?

A: We can handle both situations! If you have a suitable printable CAD file (STEP, STL, etc.) we will optimize it. If you need a model or reference image created from scratch, our design engineering team can develop accurate, manufacturable 3D models of your puzzle pieces. Design services are quoted separately.

- Q: Is plastic 3D printing an option?

Answer: Of course. For lighter weight displays, cosplay, or more budget-conscious projects, we offer high-resolution plastic 3D printing using technologies such as SLS (nylon) or resin (SLA/DLP). They can also be painted or finished to a high standard, although they don’t have the weight of metal.

Unlock your vision with GreatLight – where complexity meets perfection. Get your custom quote today!