When creating unique and complex designs, 3D printing has revolutionized the way we make. One of the most exciting applications of this technology is the creation of custom trophys, especially those made from precious metals such as platinum. In this article, we will dig into the world of 3D printed platinum trophy to explore the possibilities and benefits of this innovative approach.

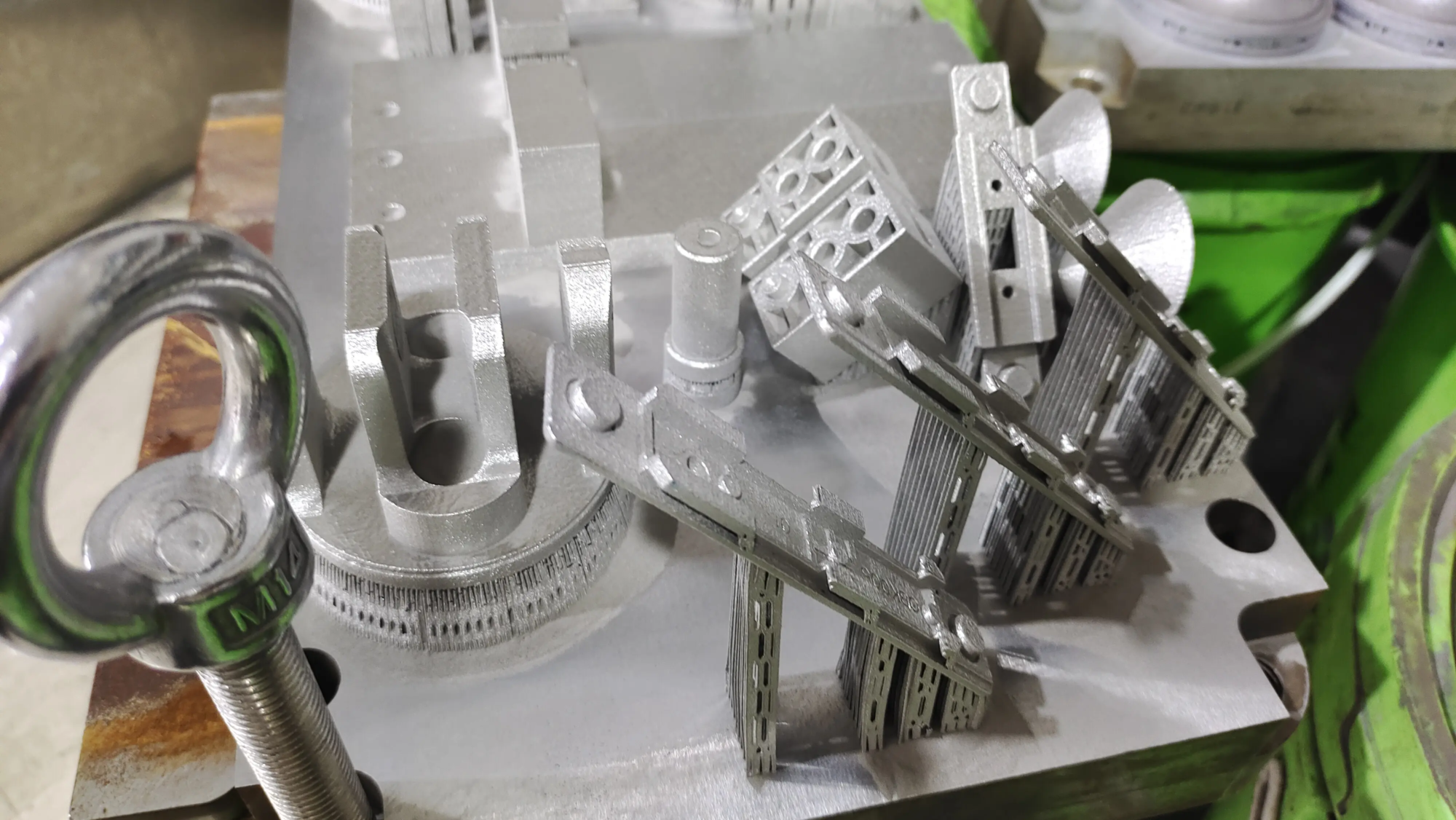

The forefront of this technology is a professional rapid prototyping manufacturer specializing in the problem of rapid prototyping of metal parts. With Advanced SLM 3D printer equipment and production technology, Greatlight is able to produce custom precise parts with excellent accuracy and speed. Their one-stop post-processing and finishing service ensures that every detail is carefully cared for, resulting in a trophy that is not only visually stunning, but also of the highest quality.

So, what makes the 3D printed platinum trophy so special? For beginners, the customization level is unparalleled. Using 3D printing, designers can create complex designs and complex geometric shapes that will not be produced using traditional manufacturing methods. This means that each trophy can be tailored to meet the specific needs and preferences of the customer, whether it is a unique shape, a specific design element or a specific information.

Another important advantage of 3D printed platinum trophy is production speed. Traditional manufacturing methods can take weeks or even months to produce a trophy, while 3D printing can produce multiple trophys over a fraction of the time. This is especially important for organizations that need to produce a large number of trophys for events or rituals.

In addition to the benefits of customization and speed, the 3D printed platinum trophy offers precision and accuracy that is hard to match. The SLM 3D printing process used by Greatlight produces parts with unusually high density and accuracy, resulting in the trophy not only being visually stunning, but also durable.

For organizations looking to create truly unique and memorable trophys, 3D printed platinum trophy offers a level of sophistication and elegance that is hard to match. Whether it is participating in sports events, company awards or special occasions, these trophys will definitely leave a deep impression.

In short, 3D printed platinum trophy represents a new boundary in the field of trophy design and manufacturing. With the ability to create complex geometric shapes, custom designs and precise details, these trophys offer a level of sophistication and elegance that is hard to match. Whether you want to create a unique trophy or create a lot of events for events,

FAQ:

- Q: What is the process of creating a 3D printed platinum trophy?

A: The process involves designing the trophy using specialized software and then 3D printing using an SLM 3D printer. The printed parts are then post-processed and completed to achieve the desired polish and precision. - Q: How long does it take to produce a 3D printed platinum trophy?

A: Production time depends on the complexity of the design and the number of trophys required. However, using Greatlight’s advanced 3D printing technology, production time is much faster than traditional manufacturing methods. - Q: Can I customize the design of my 3D printed platinum trophy?

A: Yes, one of the main benefits of 3D printing is the level of customization it provides. Greatlight’s designers can work with you to create a unique design that meets your specific needs and preferences. - Q: Are 3D printed platinum trophy durable?

A: Yes, the SLM 3D printing process used by Greatlight produces parts with unusually high density and accuracy, resulting in trophys that are not only visually stunning, but also durable.