Securely Connected Unsung Hero: 3D Printed Plug Comfort Equipment

We’ve all been there: You can plug in a laptop charger or critical medical device just to plug it, destroying power and productivity. Loose electrical connections are not only annoying, but also pose a security risk, causing damage to the device and triggering data loss. enter Insert comfortable equipment: A deceptive and simple solution designed to lock the plug to the socket. In Greatlight, we use Advanced 3D printing technology To revolutionize the way these devices are made to unlock unprecedented customization, speed and reliability.

Why is a comfortable plug important

The plug sticker has a small but powerful electrical stability guardian. They clamp to the plug and socket, eliminating the disconnection of accidental tugs or vibrations. Ideal for industrial machinery, medical equipment, smart home equipment and rough outdoor tools to ensure uninterrupted operation. Traditional mass-produced versions lack versatility – they "A small suitable person" In this world, sockets, plugs and environmental requirements vary greatly.

This is 3D printing shine.

3D Printing: Custom Plug Comfortable Game Changer

1. Exceeded quantization

There is even greater difference between electrical sockets (in the US Type A and Europe Type C) and industrial plugs. With 3D printing, we create tailor-made plugs for comfort Your exact socket size and plug type. Whether it’s a proprietary medical device plug or a three-pronged industrial connector, we digitally model and print a fit solution.

2. Quick iteration

Prototype is the key. Do you need to design adjustments after testing? Our SLM (Selective Laser Melting) and SLS (Selective Laser Sintering) Metal Printers Generate functional prototypes within 24-48 hours. Compare it to the weeks of traditional tools. Engineers can quickly test changes (adjust grip tension, weight, or reduce stress) without delay.

3. Material flexibility

The plug must be balanced Durability, insulation and flexibility. Greglight offer:

- Engineering thermoplastics: Nylon (PA12) is used for impact resistance, TPU for flexible grips.

- High temperature resin: Take heat near the machine.

- Metal alloy: Stainless steel or aluminum for extreme environments (e.g., oil rigs, aerospace).

4. Functional integration

3D printing can be designed by injection molding. Add cable clamps, water-resistant seals or RFID tags for maintenance tracking – all in a single print.

Greglight’s end-to-end expertise

As a leader Accurate rapid prototypingwe deal with each stage:

- Design support: Our engineers optimized 3D printed CAD files to ensure structural integrity.

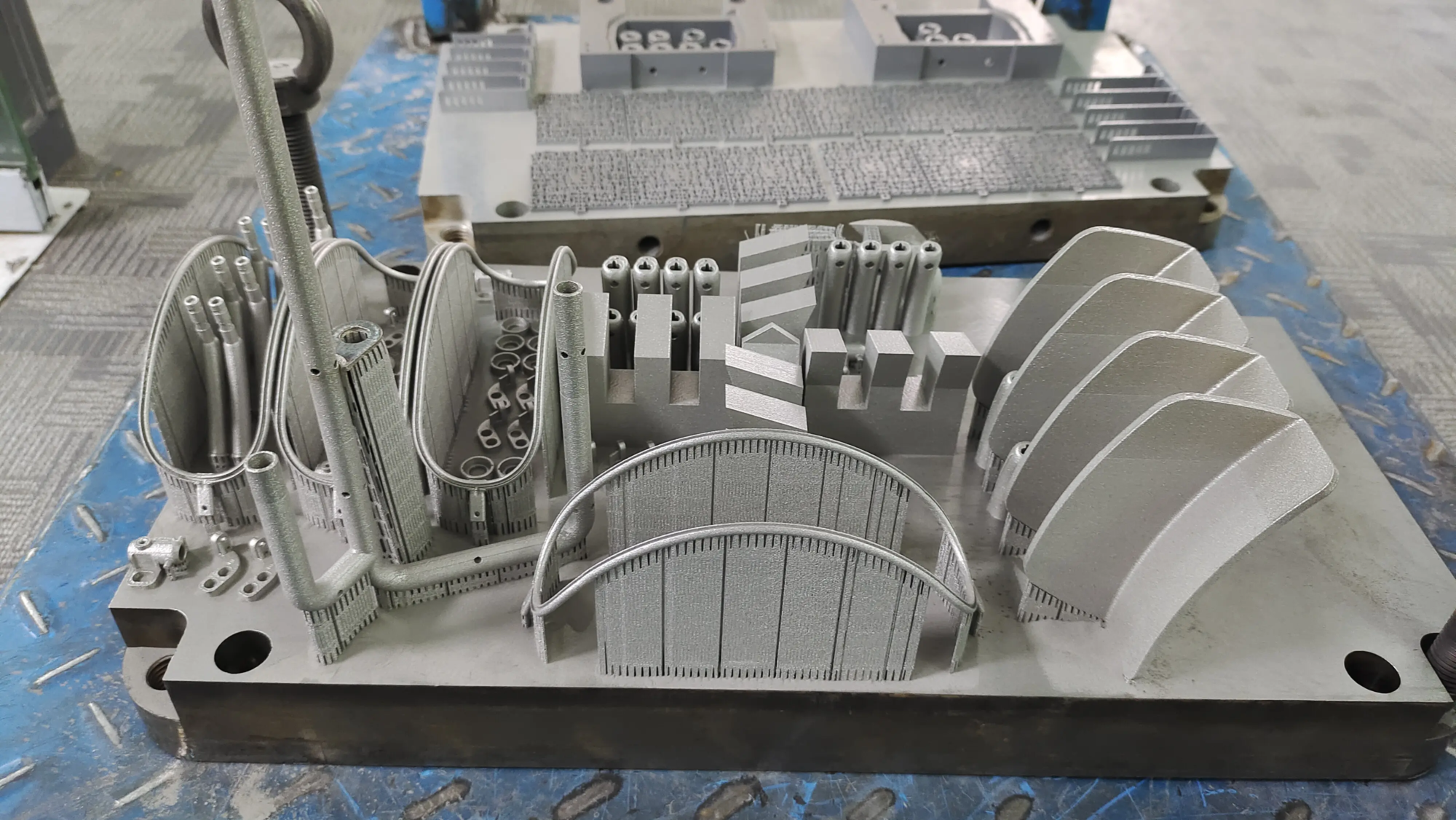

- Advanced Printing: 16+ metal/polymer printer, including SLM 3D Printerachieves an accuracy of ±0.1mm.

- Post-processing: Smoothing, heat treatment, electroplating or powder coating for aesthetics and protection.

- verify: Electrical insulation test, stress simulation and real-world test.

example: A robot customer needs a vibration-resistant plug for offshore drones. We use silicone grips for titanium comfort-salted water exposure and over 200 hours of operation.

in conclusion

The era of universal, fragile plug holders is over. 3D printed plug comfort equipment Combining customization functions with powerful engineering to solve source connection failures. Great One-stop rapid prototyping service The authorized industry demands perfection – whether it is a prototype of 10 units or 10,000 production parts. With cutting-edge technology and materials science expertise, we turn key pain points into seamless solutions.

Text protects your connection. Request a quote today.

FAQ: 3D printed plug comfort equipment

Q1: How comfortable is the plug for 3D printing and the durability of plastic injection?

A: Our nylon or metal 3D printing is comfortable Exceed Injectable version strength. SLM printed metals (such as stainless steel) offer tensile strength up to 1,100 MPa, making them ideal for high-pressure industrial uses. The polymer is subjected to UV/chemical treatment to obtain additional elasticity.

Q2: Can I customize the plug comfort for unique pin configuration?

Answer: Absolute. Share your plug/socket CAD file or dimensions, we will design an exact fit – even for non-standard or oval pins.

Q3: Are 3D printed parts electrically safe?

A: Yes. We use UL 94 V-0 rated (flame retardant) materials and apply thermal insulation coating. Dielectric strength testing ensures no conductivity risk.

Question 4: What time is the turnover time?

Answer: Prototype: 1-3 days. Production batch: 1-2 weeks. An expedited selection is available.

Q5: Can the plug handle harsh environments (heat, chemicals)?

A: The maximum temperature of metal comfort is 1,000°C. For acidic/oil settings, PEK polymer or nickel-plated coatings can add protection.

Question 6: Do you support small batch orders?

A: Yes. Unlike traditional factories, we avoid expensive molds – making small runs cost-effective. Order 1 or 1,000 units, with minimal price difference.

Question 7: How to start a project?

A: Visit Greatlight’s platform, upload specifications, and our team will provide DFM feedback and pricing within 4 hours.

About Greatlime:

Greatlight’s top rapid prototyping partner in China, blending futuristic SLM/SLS 3D printing, CNC machining and post-processing under one roof. We specialize in mission-critical metal and polymer parts, with speed + quality for the automotive, medical technology and robotics fields. Customize your project at a competitive pace, in which case innovation is in line with industrial perseverance.