Advancing the Future: Unleashing Innovation with 3D Printed Propellers

Remember the pleasure of launching a handmade Balsamu plane, watching it soar? Now imagine being able to design, customize and quickly produce aircraft, and also produce high performance Transmitter Optimized specifically for it – within a few days. This is a feature unlocked by 3D printing technology, especially when used when creating complex propeller emitters. In addition to simple models, these transmitters represent a fusion of advanced engineering, rapid iteration and accessible manufacturing that fundamentally transforms the life of prototypes and functional devices.

For engineers, hobbyists, educators and innovators, seeking dynamic testing platforms (3D printed propeller transmitters) for propulsion systems or driverless cars (UAVS) offer unprecedented freedom.

Why 3D printing is revolutionizing and advancing prototypes

Traditional manufacturing methods of complex mechanical equipment such as propeller emitters often face significant obstacles:

- High cost: The cost of CNC machining or injection molding for single-use or small-batch prototypes is too high.

- Long delivery time: Tools and settings delays kill the innovation cycle.

- Design constraints: Complex internal geometric shapes (gears, ratchets, trigger mechanisms) or organic shapes that are difficult to maneuver effectively.

- Limited customization: Standard emitters that adapt to specific propeller size or thrust requirements are cumbersome.

3D printing, especially industrial technologies, such as selective laser melting (SLM) for metals and advanced SLS/FDM for polymers, mask these obstacles. It enables:

- Geometric freedom: Create complex mechanisms, integrate bearings, internal channels for potential pneumatic integration and seamlessly optimize ergonomic processing in a single print or minimal component.

- Quick iteration: Design defects identified during testing? Adjust the CAD model immediately and print a revised prototype in a few hours to accelerate R&D exponentially.

- Lightweight and topological optimization: The software can only algorithmically remove materials when needed, thereby creating a well-structured ultralight emitter at critical pressure points that does not compromise intensity.

- Custom: Effortlessly tailor the start angle, trigger mechanism resistance, gear ratios for torque multiplication, and fixer sizes to perfectly match unique propeller or project requirements.

- Material Diversity: Take advantage of the specific characteristics of each part – impact polymers of the human body, flexible TPU grips, and high-strength metals such as Alsi10mg, titanium alloy (TI6AL4V) or stainless steel (316L/17-4PH) for critical stress components (such as gears or release rods).

From concept to thrust: Printed launcher journey

Creating a high-performance 3D printed propeller emitter involves a meticulous process that requires engineering creativity and manufacturing accuracy:

- Precision CAD design: Using advanced software (SolidWorks, Fusion 360, NX), engineers design each component – the base frame, winding mechanism (manual crank or gear), a safe propeller cradle, trigger/release mechanism, and potential hydraulic or pneumatic auxiliary ports. Key factors such as bearing friction, inter-gear tolerance (usually down to microns), potential torsion and kinetic energy transfer are accurately modeled. Stress simulation (FEA) predicts performance under load.

- Strategic material selection: Each component has different choices:

- High pressure mechanism: For gears, release hooks, torsion springs, SLM printed metal alloys (Alsi10mg for stiffness/weight, final strength of Ti64, 17-4PH for fatigue resistance) ensure durability and prevent deformation. Greatlight’s expertise in optimizing metal printing parameters ensures minimal porosity and maximum part integrity.

- Structural framework: Rigid polymers such as nylon PA11/PA12, reinforced with rigid metals such as carbon fiber (SLS/FFF) or aluminum alloys, provide strong support.

- Grip and Ergonomics: Flexible filaments like TPUs provide comfort and anti-slip surfaces.

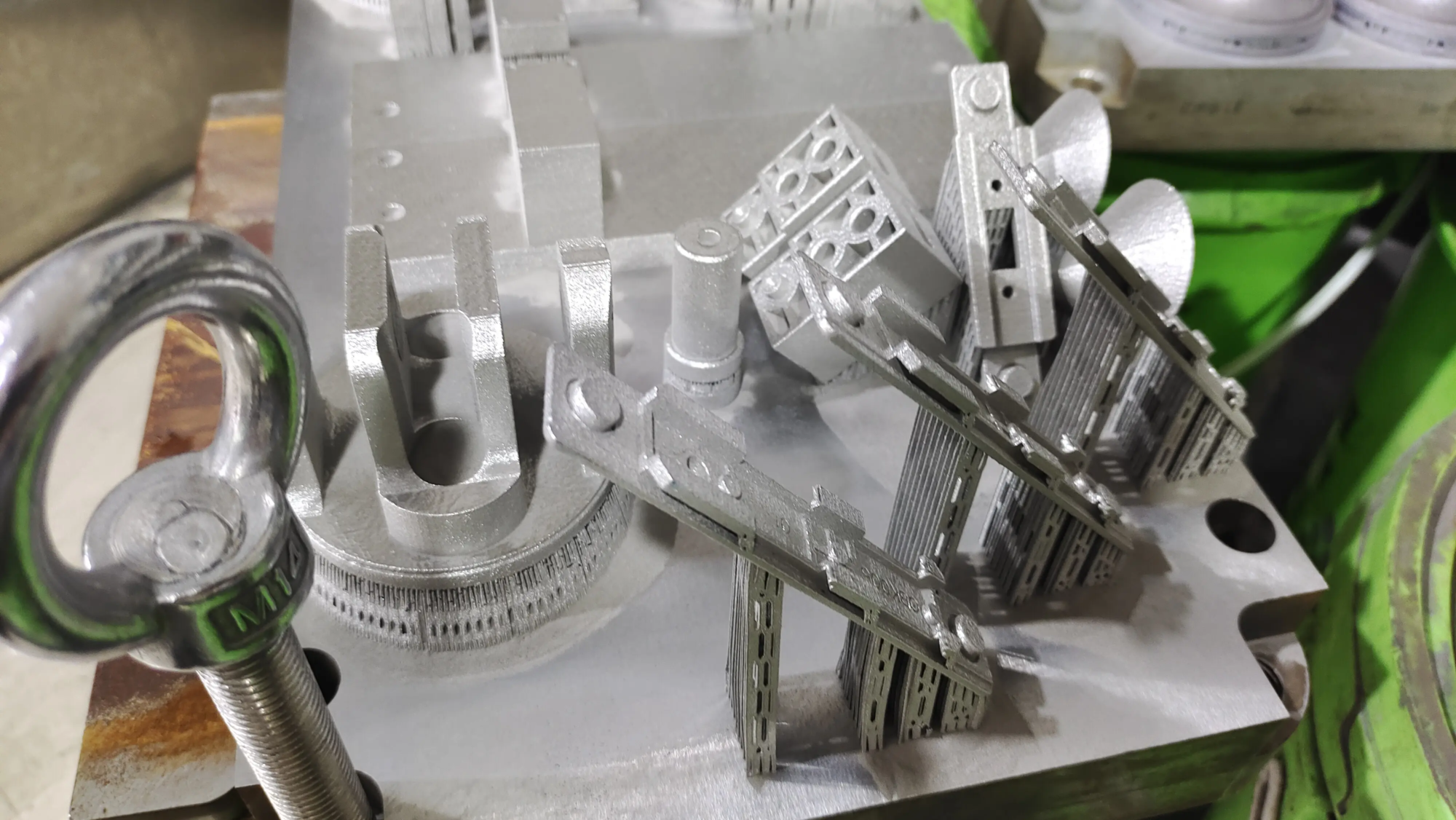

- Advanced 3D printing: Making metal components with Greatlight’s industrial-grade SLM computer ensures precise melting of metal powder layers (down to 20-30 microns) to achieve near-mesh-shaped parts with a strength comparable to forged metals. Use SLS or high temperature FDM to produce polymer parts for dimensional accuracy and detail, including internal channels.

- Key post-processing: The original version needs improvement. Greglight’s comprehensive one-stop organization service processing:

- Support removal: Carefully detach the metal or polymer support structure.

- Surface treatment: Used for polishing, tumbling or smoothing (vapor polishing of polymers) that enhance aesthetics and functionality.

- Heat treatment: Used in critical metal components (especially TI6AL4V or Steels) to relieve internal stress and obtain optimal metallurgical properties.

- Precision machining: Post-print CNC machining of critical interfaces (e.g., bearing seats) is only a separate printing function (usually +/- 0.025mm) to achieve tolerances.

- Assembly and lubrication: Final assembly of moving parts and equipped with appropriate lubricant.

- Strict test: The generator measures the emission force and torque. High-speed camera analyzes release mechanics and rotational dynamics. Iterative redesign based on test data is implemented quickly, taking advantage of the speed of the process.

Unlocking potential: Applications outside the studio

3D printed propeller transmitters far outweigh toys:

- Drone propulsion research: Quickly test and optimize new propeller designs under realistic launch conditions for improvement and efficiency and simulate a variety of drone configurations.

- Educational tools: Physics Laboratories can demonstrate rotational dynamics, angular momentum, energy transfer, and aerodynamics through customizable student safety transmitters.

- Amateurs and Competition: Remote-controlled aircraft enthusiasts have built high-performance custom launchers for specific model requirements or competitions in scale.

- Proof of Concept: Verify the mechanisms and ergonomics of auxiliary propulsion systems before committing to expensive production tools.

- Exploration platform: Potential adaptation includes activating specialized projectiles or sensors in field studies.

in conclusion

3D printed propeller transmitters reflect the transformative power of additive manufacturing in mechanical design. It goes beyond static models to enter the realm of high performance, functional prototypes and end-use components. The ability to iterate rapidly through complex geometries, leverage tailored materials and integrate complex mechanisms paves the way for unprecedented innovation and dynamic testing equipment in the propulsion system. Now, once months of processing and high costs are required, it can be achieved with precision and reliability in a few days.

As a leader in professional rapid prototyping, Gremphime empowers this innovation. With our advanced SLM metal printers and comprehensive material capabilities, we provide the industrial-grade manufacturing muscles needed to turn complex transmitter designs into powerful functional reality. Our one-stop post-processing and finishing services, coupled with deep expertise, ensure that your propeller transmitter not only starts the prototype but also succeeds when it comes to printing optimizing mechanical properties. We effectively address the complex metal rapid prototyping challenges and offer unparalleled customization at competitive prices, which is truly one of China’s major rapid prototyping partners. Ready to quickly create the next breakthrough rapid prototype?

Customize your precision propeller emitter assembly now!

FAQ (FAQ)

-

Q: What are the strength limits for 3D printing transmitter parts, especially gears?

one: It depends on the material and printing technology. Metal components produced by SLMs such as ALSI10MG or TI6AL4V exhibit very close, sometimes exceeding their cast or forged strength, suitable for heavy dynamic loads. High-performance polymers such as carbon fiber reinforced nylon are ideal for many structural components. Greatlight utilizes optimized parameters and post-treatment, such as heat treatment, to provide mechanical integrity and fatigue life specifically for functional mechanisms. -

Q: Can I print the entire propeller emitter in one piece?

one: Although it may be a polymer version in theory, it is usually not practical or desirable. The integrated mechanism (gear, spring, bearing) requires different materials and finishes to smooth the operation. Dividing the starter into key subassemblies (e.g. winding mechanisms, frames, release triggers) allows for optimal material selection, easier maintenance and easier wear-part replacement. Greglight can advise on effective design assembly strategies. -

Q: Can I get the speed of working prototypes?

one: Speed is a major advantage. Within 3-5 working days after finalization of the design, medium-complex polymer emitter prototypes may be delivered within 3-5 working days. Complex metal components that require printing, post-processing, and assembly can take 7-10 business days. Iteratively fast – The design changes that can be changed for the next print are much faster than traditional methods. Gremight stands out with fast turnaround without compromising quality. -

Q: Are 3D printed transmitters safe for high-power applications?

one: Safety is crucial. They can be extremely safe when designed by qualified engineers using appropriate engineering analysis (FEA) and manufactured using industrial grade 3D printers with certified materials. Greatlight specifies materials based on application pressure, ensures careful quality control and recommends the inclusion of a large number of safety factors into the design. Strict testing is crucial before deploying the maximum force. Security protocols are always prioritized. -

Q: What is the cost difference between 3D printing and CNC machining similar starters?

one: For prototypes and low to neutral yields, 3D printing is usually significant Fewer More expensive than CNC processing. This is due to the elimination of expensive tools and complex setups. While mass production may ultimately benefit injection models of polymers, the minimum upfront cost and design flexibility of 3D Printing makes it ideal for development and customization/small batch operations. Greatlight offers competitive prices specifically targeting fast prototype budgets. - Q: Will Greatlight handle design, or only manufacturing?

one: Greglight performs outstandingly in professionally manufactured and finished parts based primarily on the CAD design you provide. We provide comprehensive design for additive manufacturing (DFAM) consultation optimization Your existing 3D printing performance and cost-effective design. For a comprehensive turnkey design service, we can connect you with qualified engineering partners. Our strength lies in the rapid transformation of proven design into high-precision physical parts.