Unlocking Customization and Speed: A Practical Guide to 3D Printing PVC Accessories

PVC (polyvinyl chloride) fittings are ubiquitous in plumbing, irrigation, and industrial applications and are valued for their durability, chemical resistance, and affordability. Custom PVC components have traditionally been manufactured through injection molding, often facing obstacles such as high tooling costs and long lead times. This is where 3D printing emerges as a transformative solution. While presenting unique challenges, additive manufacturing brings unprecedented flexibility for custom parts, rapid iteration and low-volume production. This guide explores the intricacies of the problem, its solutions, and why working with an expert like GreatLight can improve your success.

Why choose 3D printed PVC accessories?

The motivation is clear:

- custom made: Creating complex geometries (threads, unique angles, integrated features) is either impossible or expensive with molds.

- Rapid prototyping: Iterate on designs in hours or days instead of weeks, speeding up development cycles.

- Small batch production: Economically produce small batches without large upfront tool investments.

- Replace as needed: Quickly manufacture obsolete or hard-to-source parts.

- Material optimization: Try using modified PVC blends or performance-specific alternatives.

Meeting the challenge: successfully printing PVC

Printing pure, standard PVC filament is notoriously difficult; Potential danger. When heated beyond its processing point, PVC decomposes, releasing toxic hydrogen chloride (HCl) gas. This requires strict security measures. Additionally, PVC has properties that require careful handling:

-

Toxicity and Safety (Priority #1):

- Ventilation is non-negotiable: always prints on Well ventilated area – It is best to have a dedicated outdoor exhaust device. no way Print PVC in an unventilated room.

- Air filtration: It is highly recommended to use a HEPA filter with activated carbon to capture particulate matter and neutralize acid gases. Enclosed printers are a must.

- Printer upgrade: use All metal hot end Capable of sustained high temperatures (250°C+, see below). Hardened steel nozzles are critical because PVC (especially with additives) can be abrasive.

-

Materials and Filament Alternatives:

- PVC blends: Special filaments such as PVC-U (not plasticized), PVC-C (chlorinated)or proprietary blends (e.g., "PVC-like") formulas from well-known brands that can be printed more easily while retaining key attributes. These typically require lower extrusion temperatures (220-250°C compared to 260°C+ for virgin PVC) and significantly reduce HCl release (although ventilation is still critical).

- Alternative materials: Consider whether specific PVC properties are critical. ABS is tough, nylon (PA) is impact-resistant and chemically stable, and specialty materials such as PP (polypropylene) have good chemical resistance. For pressurized applications, metal printing may be required. GreatLight specializes in identifying the best material alternatives or hybrids for functional parts through SLM/SLS technology, as our expertise has expanded from polymers to advanced metals.

-

Printing parameters and technology:

- High extrusion temperature: Expected temperatures are 230-260°C (always within filament manufacturer specifications). Precise temperature control is crucial.

- Heated build plate (required): 80-100°C can significantly improve the adhesion of the initial layer. Use adhesion aids such as PEI sheets, specialized printing plate surfaces, or carefully selected adhesives.

- Bed leveling and surface preparation: Impeccable first layer adhesion prevents warping. Carefully clean the build surface.

- Printing speed is slow: Optimization range is 30-60 mm/sec. Slow speed (especially the first layer) enhances adhesion and bonding between layers.

- Minimum cooling fan: Disable or significantly reduce fan speed (<20%). The PVC layers need to be fused together; cooling can cause warping and thin layer bonding.

- High retraction setting: Carefully adjust retraction to minimize leakage and stringing.

- Dry filament: PVC blends absorb moisture quickly. Store sealed with desiccant and dry before printing (~40-50°C, 4-6 hours).

- Post-processing:

- Polishing: Achieve a smoother surface for a better seal.

- Chemical Smoothing (with caution): Solvents such as tetrahydrofuran (THF) can work, but they can also be dangerous. Extreme personal protective equipment and ventilation are required – often best left to professionals.

- test: Thoroughly test fittings, especially when replacing traditional PVC parts, for pressure integrity and chemical compatibility. Hydrostatic testing is common in pipeline applications.

Why partner with GreatLight on the 3D printed PVC accessories project?

While DIY printing is possible for experienced users (safety first!), utilizing a professional 3D printing service offers significant advantages, especially for functional or critical components:

- Security expertise and infrastructure: We manage toxic fumes through engineered industrial ventilation, filtration (HEPA + activated carbon) and strict safety protocols in a controlled environment – eliminating DIY risks.

- Advanced materials knowledge: Our engineers guide material selection, whether optimizing PVC blends, engineering-grade alternatives (ABS, Nylon, PP), or transitioning to stronger and more durable materials SLM printed metal parts When ultimate strength, pressure resistance or temperature resistance is critical.

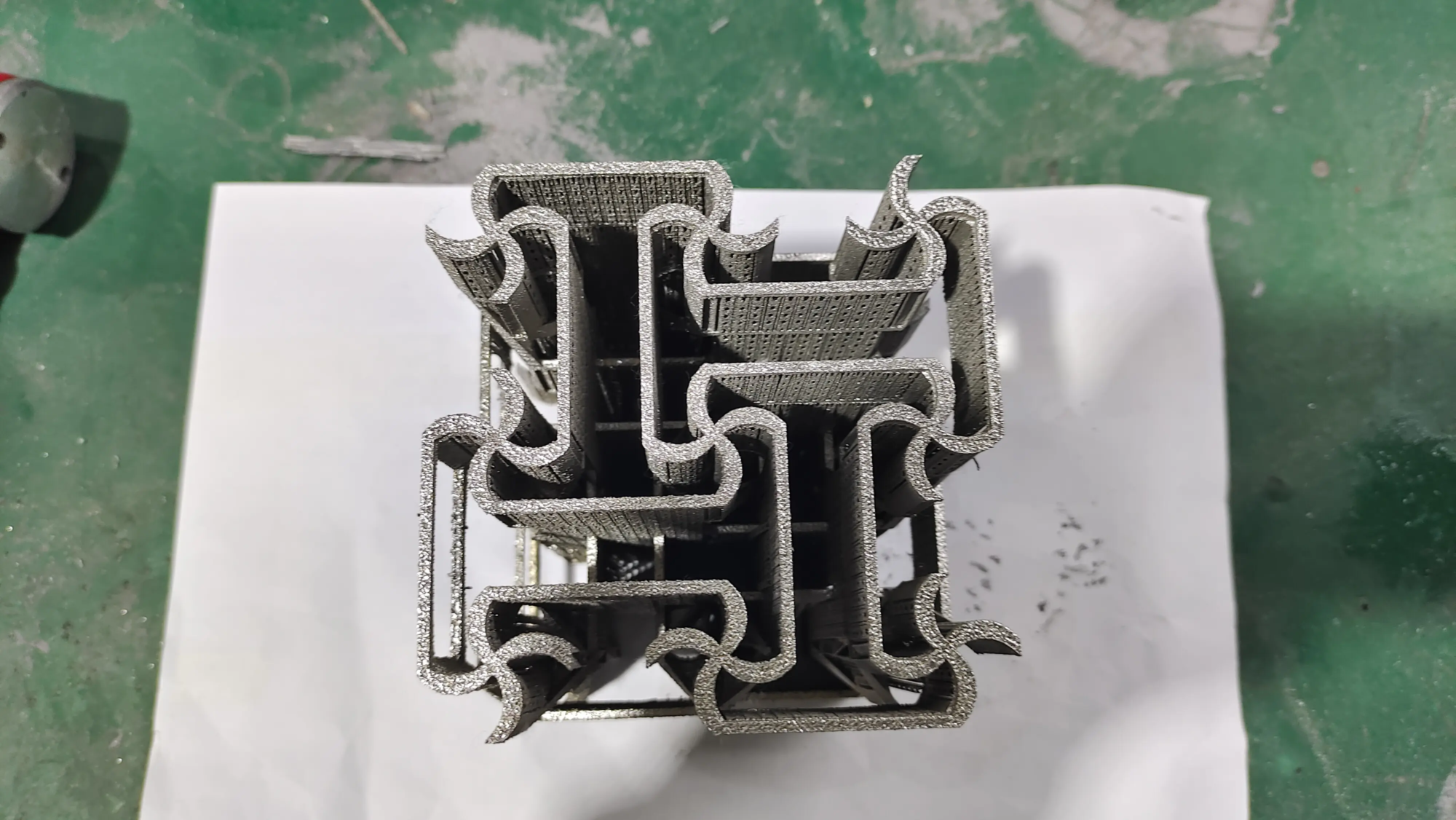

- High-precision equipment: Industrial grade printers (FDM, SLS, SLM) ensure dimensional accuracy, consistency and reliable printing of challenging materials beyond the capabilities of hobbyists. Our SLM technology enables complex, durable metal parts not possible with filament printing.

- Superior surface finish and sealing: Advanced post-processing (precision machining, sandblasting, specialized sealing technology) ensures flawless operation of performance-critical components, guaranteeing tight sealing and long-term reliability under pressure.

- One-stop manufacturing solution: From design optimization and materials consultation to printing, finishing, rigorous testing and quality control – GreatLight provides seamless integration. Avoid juggling multiple vendors.

- Speed and scalability: Quick turnaround time meets urgent prototyping needs. Seamlessly transition from prototype production to low-volume functional production.

in conclusion

3D printed PVC fittings offer exciting opportunities for custom design and rapid manufacturing, requiring respect for material challenges and safety. While hobbyists can achieve results with specialized filaments and meticulous safety procedures, complex applications or critical pressure/vacuum sealing require specialized knowledge. GreatLight provides the EAT (Expertise, Authority, Credibility) necessary to achieve reliable results. We combine advanced technology (including cutting-edge SLM metal printing), deep materials knowledge, strict safety compliance and comprehensive post-processing capabilities to ensure that your PVC or alternative material parts meet the most stringent specifications. Embrace innovation and efficiency – discover how 3D printing can revolutionize your custom accessory solutions.

FAQ: 3D Printed PVC Accessories

Q: Is it safe to 3D print PVC at home?

one: print standard PVC filament is strongly frowned upon for releasing toxic HCl gas, requiring special ventilation and filtration that is difficult to achieve safely in a home environment. specialized "PVC-like" Mixtures with stricter safety data sheets are safer alternatives experienced User use Fully enclosed printer with HEPA + activated carbon filter. However, For PVC or its alternatives, it is always recommended to use a professional printing service like GreatLight Thanks to our industrial security infrastructure.

Q: What are some good alternatives to PVC filament for printing accessories?

one: Viable alternatives depend on functionality:

- ABS: Good toughness and impact resistance. A casing is required to prevent deformation.

- Peteg: Good chemical resistance, strength, easier to print than ABS/PVC. Ideal for less demanding fluid applications.

- Nylon (PA6/PA12): High strength, excellent impact resistance, good chemical resistance (usually equal to/better than PVC). Hygroscopic (absorbs water), may require drying.

- PP (polypropylene): Excellent chemical resistance, flexible and durable. Printing would be challenging without advanced bed bonding technology.

- Metal (SLM/SLS): Meet critical pressure, temperature or chemical resistance requirements (stainless steel 316L, aluminum, titanium). Powered by GreatLight through our advanced SLM capabilities.

Q: Can 3D printed PVC fittings withstand pressure (such as water pipes)?

one: Extreme caution is required. Achieving a watertight or airtight seal is difficult. Printed parts may have microscopic defects that can cause leaks. Under sustained pressure, interlayer adhesion may weaken. Requires extensive post-processing and sealing. Stress capacity is usually Significantly lower than molded PVC. Over-engineered walls and rigorous pressure testing (static/pneumatic) post-production are critical. For critical pressurized systems, printing on metal (SLM) is often safer and more reliable.

Q: How to prevent PVC printed matter from deforming?

one: Focus on: Ultra-clean build surface, Heated bed (80-100°C), closed build room, No cooling fan, Perfect leveling, Big brim/skirt, Good bed bonding aids (e.g. specialty adhesives, PEI)and print slowly as needed For the first layer.

Q: Why choose GreatLight instead of DIY to make PVC-like accessories?

one: GreatLight reduces critical risks (safety, material handling, part failure) and provides guaranteed quality by:

- Industrial scale ventilation and air filtration systems.

- Expertise in material selection, process optimization, and printing challenging polymers or metals.

- Use high-performance industrial printers and post-processing technology.

- Strict quality control and testing protocols for functional parts.

- "one stop shop" Services from file optimization to finished products and test components.

Q: Does GreatLight offer prototypes made from real PVC?

one: Due to significant hazards and material process complexities, we often use advanced PVC replacement filaments for functional polymer prototypes or transition customers to SLS (for complex polymers) or SLM metal printing Suitable for parts requiring similar/better performance (strength, corrosion resistance). This approach ensures safety and part performance while meeting expectations for quick turnaround. Our materials science team can provide recommendations on the best alternatives based on your specific requirements.