As a DIY enthusiast or professional contractor, you may be familiar with the Ryobi brand and its wide range of power tools. However, one of the most frustrating problems with these tools is the battery case, which can be damaged or lost. This is where 3D printing is located – this technology has revolutionized the way we design and manufacture custom parts. In this article, we will explore how to print the Ryobi battery case, the benefits of doing so, and what to do to get started.

Benefits of 3D Printing Ryobi Battery Case

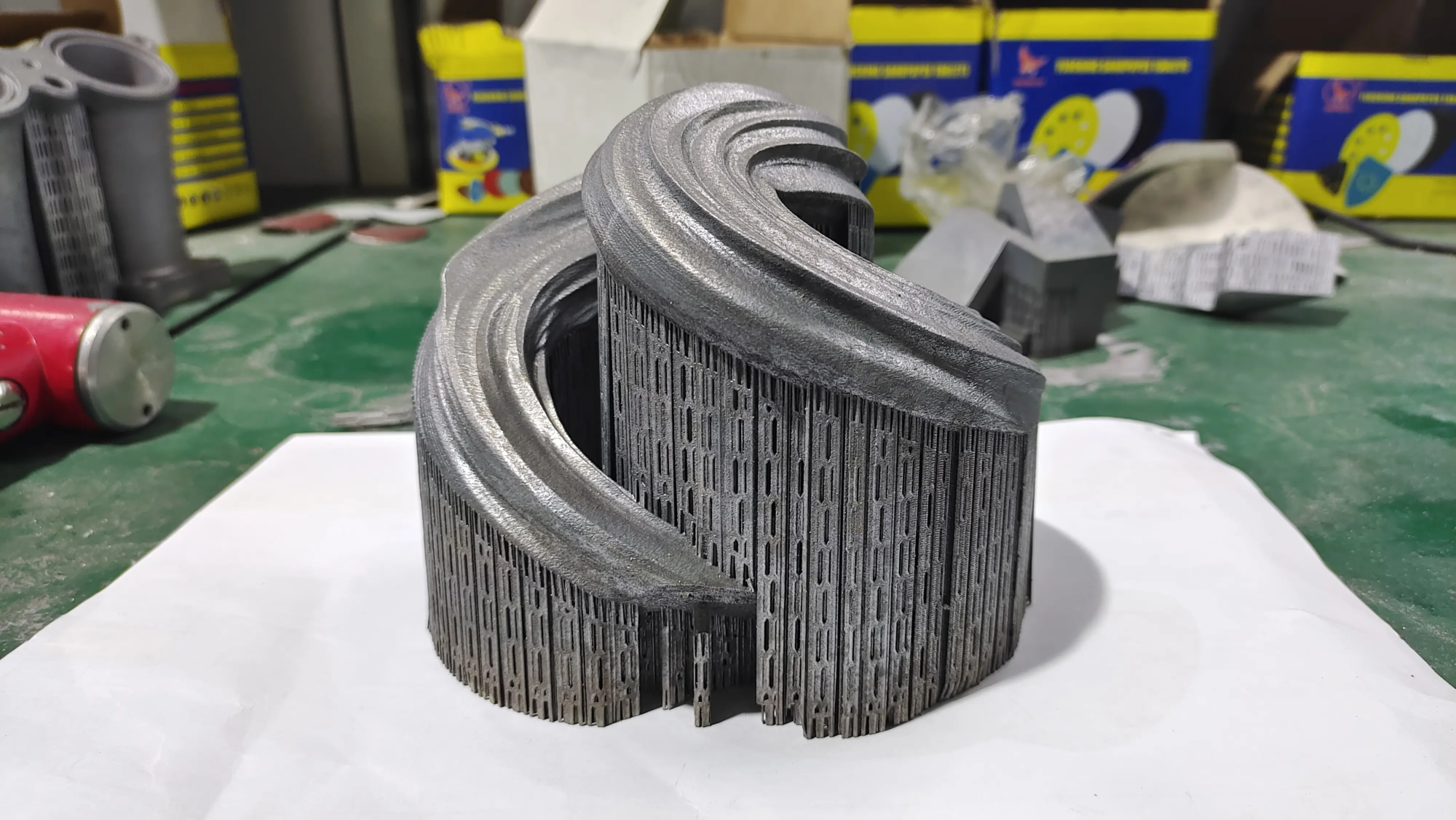

3D printed Ryobi battery boxes have several advantages over traditional manufacturing methods. First, it can be prototyping and production quickly, which means you can quickly create custom battery boxes that meet your specific needs. Furthermore, 3D printing can use complex geometric shapes and designs, and traditional methods are difficult or impossible to produce. This means you can create battery cases using custom features such as other compartments or mounting points, which are tailored to specific use cases.

Another benefit of 3D printing of Ryobi battery cases is cost savings. Traditional manufacturing methods can be expensive, especially for small quantities. With 3D printing, you can produce a single battery box at a fraction of the cost of the traditional method. This is an attractive option for DIY enthusiasts or small businesses who need to produce custom parts.

Design and print battery cases

To 3D print the Ryobi battery case, you need to design the case using computer-aided design (CAD) software. There are many CAD software options available, ranging from free and open source options such as blenders to commercial options like SolidWorks. After designing the case, you can export it as a 3D model file that can be sent to a 3D printer for production.

When printing the battery case, you need to select the material that suits the application. Common materials used for 3D printing include plastics, metals, and ceramics. For Ryobi battery cases, durable plastic or metal materials would be a good choice as it needs to withstand rigorous use as well as potential drops or impacts.

Post-processing and completion

After printing the battery case, you may need to perform some post-processing and finishing operations to give it a professional look and feel. This may include sanding or machining the shell to smooth any rough edges or surfaces and applying paint or finish to protect the material and enhance its appearance.

in conclusion

3D printed Ryobi battery boxes are a great way to create custom parts that meet your specific needs. With rapid prototyping and production, cost savings, and the ability to create complex geometric shapes and designs, 3D printing is an attractive option for DIY enthusiasts and professionals. By designing and printing custom battery boxes, you can create a part tailored to specific use cases and needs and will provide years of reliable service.

FAQ (FAQ)

Q: Which materials can be used for 3D printed Ryobi battery cases?

A: Common materials used for 3D printing include plastics, metals and ceramics. For Ryobi battery cases, durable plastic or metal materials would be a good choice.

Q: How long does it take to 3D print the Ryobi battery case?

A: Printing time will depend on the complexity of the design, the materials used, and the functionality of the 3D printer. Usually, printing time ranges from several hours to several days.

Q: Can I use a 3D printed battery box with other power tools?

A: Yes, you can use a 3D printed battery box with other power tools as long as the box is designed to be compatible with specific tools and batteries.

Q: How much does it cost to 3D print Ryobi battery case?

A: The cost of 3D printing will depend on the materials used, the complexity of the design, and the functionality of the 3D printer. Often, the cost ranges from a few dollars to a few hundred dollars.

Q: Where can I find a 3D printing service that prints my Ryobi battery box?

A: There are many 3D printing services online, including companies such as Greatlight, which provide fast prototyping and production services. You can also check it out at your local 3D printing store or maker space in your area.