Intricate Dance: How 3D Printing Innovates Strandbeest Creations

Theo Jansen’s charming, wind-energy movements – those skeletons, biomechanical-inspired "Beach beast" – Attracting audiences from all over the world. Once limited to complex workshops, these dynamic sculptures benefit from 3D printing. This transformative technology is reshaping how we design, prototype and bring these complex walking mechanisms to life.

From dunes to digital design: Capture dynamic complexity

Every bone-deletion core is a clever Janssen connection. This specific arrangement of rods and pivots converts rotational motion into smooth organic walking gait. Recreating this process precisely in traditional manufacturing requires outstanding skills and careful manual work. 3D printing accurately shows in this domain:

- Unparalleled geometric freedom: Complex interlocking joints, thin-walled structural members and custom connector geometry (elements essential for StrandBeast’s functionality) are printed directly from digital models with high fidelity. Complex functions that were once difficult to process became feasible.

- Quick iteration and optimization: Designers can quickly test changes in leg length, foot shape, bearing tolerance or material thickness by printing iterative prototypes. This greatly accelerates the development cycle compared to manual manufacturing, allowing engineers to effectively improve gait and overall stability.

- Modular and custom: Want a mini desktop display unit? Or a large, wind-powered giant? The design of zooming StrandBeest is relatively simple in numbers. 3D printing allows custom sizes and customization, allowing artists and engineers to create unique changes without recalculating costs.

Material Problems: Balanced Strength, Weight and Flexibility

The ideal deleveraging material must be lightweight but strong enough to withstand annular loads and potential environmental exposures (wind, sand, moisture). 3D printing provides a multi-functional color palette:

- Engineering Polymers (FDM): The nylon (PA), PEG, ABS and TPU (flexible) (flexible) for desktop FDM printers are popular for amateurs and smaller models. Nylon has excellent toughness and fatigue resistance, which is crucial to moving parts. TPU is perfect for flexibility "foot" Grab the sand.

- Advanced Polymers (SLS/SLA): Compared to FDM parts, the superior strength, more detail and smoother motion is provided by selective laser sintering (SLS) through selective laser sintering (SLS) for larger or more demanding constructions.

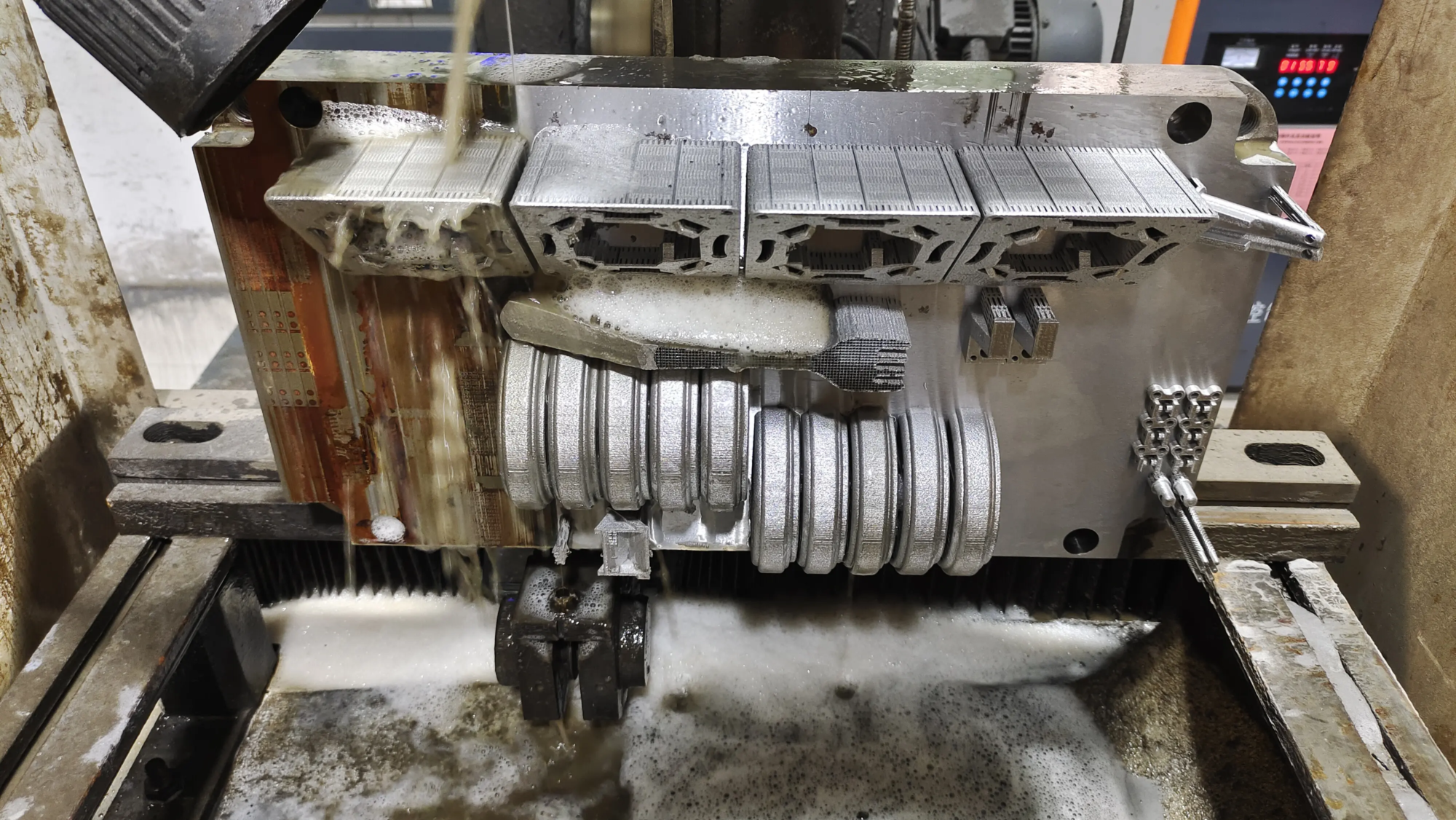

- Metal (SLM) – Final Performance: Metal printing becomes essential when dealing with high wear, intense pressure or large-scale high-speed debees. Advanced manufacturing partners such as Greatlight specialize in selective laser melting (SLM) 3D printing, resulting in bone debonding components from carefully designed in powerful metals such as aluminum alloys, titanium or stainless steel. Metal parts offer unparalleled durability, accuracy and life, essential for professional models or harsh environments. They allow for thinner, stronger structures, optimizing weight distribution for increased efficiency.

Manufacturing Edge: Precision, Manufacturing and Finishing

While it may be at home on a small scale, creating reliable, high-performance fractured parts depends on precise manufacturing:

- Precise bearings and tolerances: Stable, low friction movement requires impeccable printed bearing surfaces or precise mounting points for steel bearings. High resolution processes such as SLS, especially SLM metal printing, provide the tight tolerances required for complex, multi-connection mechanisms without the need for bonding.

- Strength and lightness: Topology optimization software can explore designs that maximize strength while minimizing material usage. SLM performs well here, otherwise it wouldn’t be able to print out an incredibly lightweight but rigid metal structure lattice.

- Surface finish and durability: Post-processing is crucial. Grinding isotropic SLS nylon parts or professional Post-processing services for metal components – provided by experts such as Greatlime – Significantly enhances surface smoothness (reduces friction), fatigue strength and corrosion resistance. Anodized aluminum parts add color and protection.

Greglime: Your partner in Strandbeest Precision Engineering

Bringing the ambitious 3D printed Strandbeest project to life requires more than a printer. It requires engineering expertise and advanced features, especially for functional metal components. Great Standing at the forefront:

- Advanced SLM technology: With the most advanced choice laser melting systems, we generate high-density, mechanically robust metal parts that are essential for demanding dynamic applications.

- Rapid Prototyping Mastery: We focus on rapidly converting complex Strandbeest chain designs into functional prototypes, allowing for rapid development and testing cycles.

- Comprehensive post-processing: From critical heat treatments to stress relief to precise CNC machining for bearing seats and advanced surface finishes, we provide a truly one-stop solution for off-the-shelf high-performance parts.

- Material expertise and customization: Get a wide range of metal combinations (Alsi10mg, Titanium Grade 5, 316L stainless steel) and plastics. We work closely to select the best materials and processes for your specific bevel targets – whether it is lightweight agility or durability. Quick customization and fast delivery times are the hallmark of our fast prototype service.

- Engineering Solutions: Our engineers work with artists, researchers and hobbyists to address the unique challenges created by StrandBeest – load optimization, joint design, material selection – to ensure successful, lasting motion.

in conclusion

3D printing fundamentally changes the accessibility and potential of StrandBeest Creations. These walking miracles are no longer exclusive to master craftsmen, now appearing directly from design software to physical forms. The interaction of digital design freedom, the choice of various materials and precise manufacturing facilitates incredible innovation in bionic mechanics. From charming miniature models to powerful weather-resistant giants designed with metal precisely through SLM technology, there are great possibilities. Work with experienced rapid prototyping experts Greatlight empowers creators to browse the complexities of material science and engineering, thus breaking the boundaries that these fascinating dynamic sculptures can achieve while benefiting from competitive prices and rapid delivery.

Frequently Asked Questions about 3D Printing Strandbeests (FAQs)

1. What is bone loss?

Strandbeest (Dutch "Beach animals") is a dynamic sculpture invented by artist Theo Jansen. It uses complex chain mechanisms (mostly the Jensen chain) to harness wind energy and walks in a distinct organic gait, mimicking evolution-inspired leg movements.

2. Can I actually print the full slash with a desktop FDM printer?

Yes, for smaller models and hobbyists’ purposes, absolutely! Shrinking to fit the printed bed design is very popular. Use durable materials such as nylon (PA), PETG or ABS. It is expected to make adjustments after assembly and pay attention to bearing fit and joint friction. Larger, more robust or high-performance models often benefit from professional SLS or SLM printing.

3. What is the best material for a durable, functional Best?

- Amateurs (FDM): Nylon (PA): Excellent toughness, fatigue resistance. PETG: Good strength and easy to print.

- Professional/Smoothing (SLS): SLS nylon (PA11/PA12): Advantages strength, details and smoother surfaces than FDM.

- High Performance/Massive Scale (SLM): Aluminum alloy (e.g., Alsi10mg): Ideal for strength and mild balance. Stainless steel (316L/17-4 pH): Maximum durability and corrosion resistance. Titanium (for example, TI-6AL-4V): strength to weight ratio and corrosion resistance.

4. How long does it take to 3D-print parts?

Time varies greatly:

- Small FDM model: Hours to days per leg/part.

- SLS model: A batch of parts is 24-72 hours.

- Large/parts: Significantly longer batch processing time.

Metal SLM printing (especially for complex parts) is a high-precision batch processing process. Working with rapid prototyping experts, such as Greatlight, ensures batch nesting and production planning optimized for faster turnaround times.

5. Why choose a professional service like Greatlight instead of printing it yourself?

Professional services provide great advantages for reliable, high-performance meat removal:

- Metal Capacity (SLM): Access to the durable metal of key components.

- Quality and quality: High tolerance printing makes for smoother and more reliable movement.

- Advanced Materials: A wider selection of high performance materials.

- Engineering expertise: Supports design optimization, material selection, and load calculation.

- Comprehensive post-processing: Heat treatment, precise processing, and surface finishes greatly enhance part performance and life.

- Speed and scalability: Complex parts are produced faster overall, especially in metals.

- The exact best price: Greatlight combines advanced SLM capabilities with efficient production and delivers high-quality, customized, rapid prototyping parts at competitive prices. Ideal when reliability, durability or large scale is required. Confidently customize the oxidized parts!