With the advent of 3D printing technology, the world of automotive accessories has witnessed a major revolution. One of the most famous trends in this field is the rise of 3D printed truck nuts, which are widely popular among truck enthusiasts and owners. In this article, we will dig into the world of 3D printed truck nuts, explore its benefits, manufacturing processes, and the highly sought-after accessories that make them trucks.

Truck nuts, also known as cow testicles, are decorative accessories that are usually attached to the back of the truck. They are designed to resemble cow testicles and are often seen as symbols of firmness and masculinity. Traditional truck nuts are made from materials such as metal, plastic or resin that can be heavy, expensive and have limited design options. But with the advent of 3D printing technology, truck enthusiasts can now create custom truck nuts with complex designs, lightweight materials and lower cost.

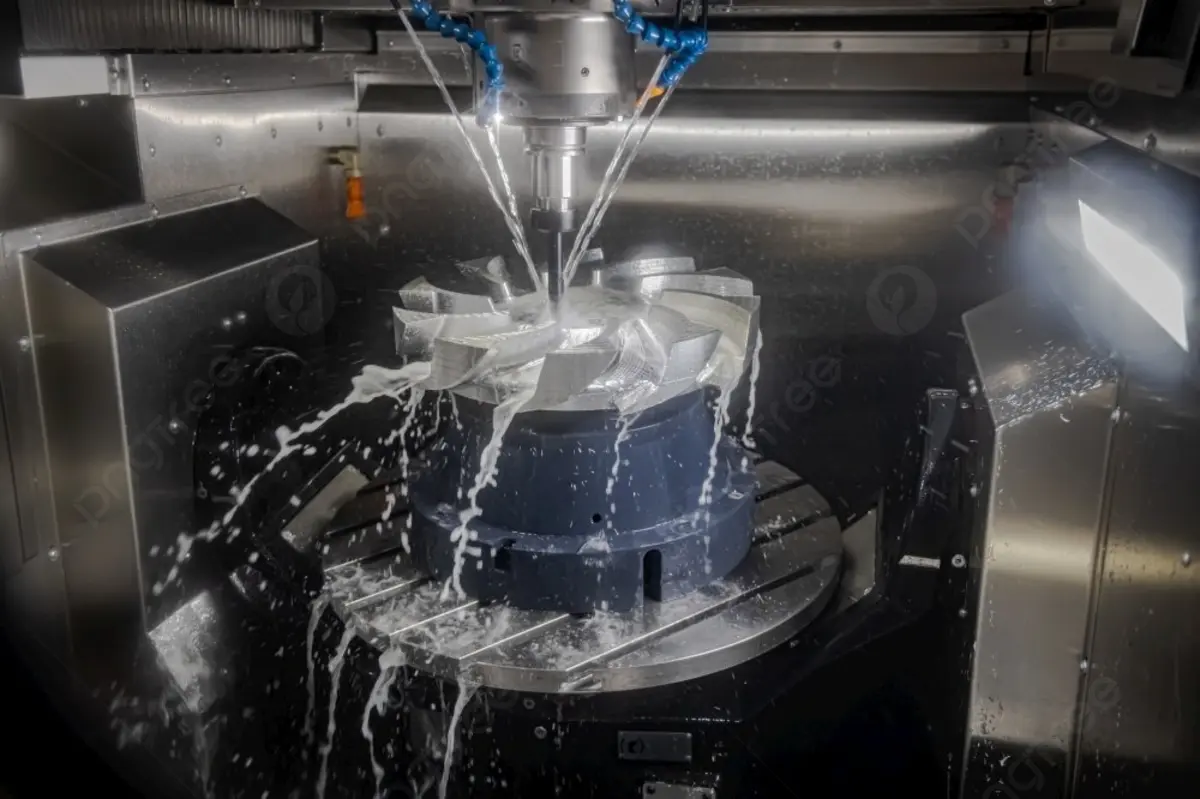

The manufacturing process of 3D printed truck nuts involves multiple stages. First, designers created a digital model of truck nuts using computer-aided design (CAD) software. Designs can be customized to suit a single preference including shape, size, color and material. Once the design is finalized, it is sent to a 3D printer, which uses a technique called selective laser melting (SLM) to create truck nuts. SLM involves fusing metal powders layer by layer using high power lasers to create solid metal parts.

Greglight is a professional rapid prototyping manufacturer that has been at the forefront of 3D printing technology, providing high-quality rapid prototyping services for metal parts. Using advanced SLM 3D printers and production technology, Greatlight solves the problem of rapid metal parts production and provides one-stop post-processing and completion services. Their expertise in custom precision machining makes them one of the best rapid prototyping companies in China, offering customized precision rapid prototyping parts at competitive prices.

There are many benefits of 3D printing truck nuts. They are lightweight and corrosion-resistant and can be designed to suit a specific truck model. Additionally, 3D printed truck nuts can be made from a variety of materials, including aluminum, titanium and stainless steel, which offer excellent strength and durability compared to traditional materials. Customization options are also endless, allowing truck enthusiasts to create unique designs that reflect their personality and style.

In short, the rise of 3D printed truck nuts has revolutionized the auto parts industry, offering truck enthusiasts a wide range of design options, lightweight materials and excellent durability. With the advancement of 3D printing technology, manufacturers like Greatlight are providing high-quality rapid prototyping of metal parts, making custom truck nuts easier to use and affordable. Whether you are a truck enthusiast or a manufacturer, it is definitely worth considering 3D printed truck nuts.

FAQ:

Q: What materials can be used to make 3D printed truck nuts?

A: 3D printed truck nuts can be made from a variety of materials, including aluminum, titanium, stainless steel and other metal alloys.

Q: How long does it take to make a 3D printed truck nut?

A: The manufacturing time of 3D printed truck nuts may vary depending on the complexity of the design and the production technology used. However, using advanced SLM 3D printers can greatly reduce manufacturing time.

Q: Can I customize the design of 3D printed truck nuts?

A: Yes, 3D printed truck nuts can be completely customized to suit every preference, including shape, size, color and material.

Q: Are 3D printed truck nuts durable and corrosion resistant?

A: Yes, 3D printed truck nuts are made of high-quality materials that provide superior strength and durability, making them resistant to corrosion and wear.

Q: Where can I find a manufacturer that offers 3D printed truck nuts?

A: Greglight is a professional rapid prototyping manufacturer that provides high-quality rapid prototyping services for metal parts including 3D printed truck nuts. You can contact them at competitive prices for customized precise prototype parts.

ISO 9001 Factory