Love, Design: Why Your Ultimate Valentine’s Day Gift Comes in a 3D Printed Box

Valentine’s Day. never quite As simple as picking up a card and chocolate, right? You want to express something deeper and more unique your – Embodiment of care, attention and unique feelings. This year, ditch the ordinary and embrace the extraordinary and give your special someone a gift Custom designed, 3D printed Valentine’s Day gift boxes. It’s more than just packaging; it’s a personal experience from concept to creation.

Beyond the wrapping paper: the soul of the gift

Think about it. The reveal moment of lifting the wrapping paper or lifting the lid is often as anticipated as the gift itself. Why choose boxes mass-produced by craft stores? The 3D printed box elevates the moment into a deeply personal statement:

- Unparalleled personalization: Weave your story into the structure. Engrave your initials or nickname in an elegant font. Incorporate meaningful symbols—the coordinates where you met, a stylized rendering of your first pets together, a lyric "your" song. Design silhouettes that resonate: intertwined hearts, delicate filigree, simple geometric patterns echo shared interests. This box is not for your lover; it is unique about them and about you. it whispers "I see you, I know you, I cherish the details."

- Functional originality: stop thinking "Box." think experience enhancer. Imagine:

- A puzzle box that requires your partner to solve a simple and meaningful combination – perhaps a date or an abbreviation.

- The multi-tiered box contains nested surprises: Inside is a ring box that cascades with petals when opened.

- Integrated hinge and buckle design provide a satisfying, sturdy feel.

- Hidden compartments, activated by sliding panels or rotating mechanisms, hold tiny secrets inside.

- Perfectly fitting compartments keep oddly shaped gifts safe and beautifully displayed.

- Integrated LED lighting elements create a soft, romantic glow when switched on.

- Exquisite material touch: Forget flimsy cardboard. 3D printing brings a symphony of touch:

- Polished metal (stainless steel, titanium): Showcasing timeless elegance and durability. Imagine that cool feeling, that solid weight whispering eternity. Finish options such as mirror polish or fine sandblasting enhance the sense of luxury.

- Strong nylon (PA12, PA11): Achieve stunningly detailed geometries not possible with traditional methods. Dye in vibrant Valentine’s Day shades or elegant black/grey.

- Simulated wood (sandstone-like polymer): Providing warmth and complex surface texture, it is often mistaken for finely crafted wood.

- Transparent/Biopolymer: Perfect for lighting design or subtly displaying content. The elegant frosted finish adds to the mystique.

The journey: from brainstorming to beautiful boxes

So, how do you summon this custom treasure? This is the path:

- spark: What is the essence? Identify the core emotion or shared memory you want the box to evoke. Gather ideas, sketches, or references.

- Blueprint creation: Convert your vision into a digital 3D model. Work with talented designers who specialize in CAD, or take advantage of intuitive online tools with support. Focus on:

- Precise interior dimensions accommodate precious gifts.

- Structurally sound design – wall thickness, hinge structure, buckles.

- Printing limitations (overhangs, tolerances) – Working with the printer early ensures feasibility.

- Surface texture and aesthetic details.

- Material and process selection: This defines the soul of the work. consider:

- Desired aesthetic (metallic luster, matte texture, transparency)?

- Durability needs? (Metal handles are best for frequent use).

- Tactile experience? (The cool weight of metal versus the warm feel of nylon).

- What are the requirements for major gifts? (Need UV protection? Shock absorption?).

- Delivery time? (SLA/Nylon/SLS cycle times may be shorter than complex metal prints).

- Professional production: This is where working with an expert becomes crucial. Entrust your carefully crafted documents to ownership advanced technology Able to transform complex geometric shapes into perfect physical forms. Focus on:

- Precise tolerances adhered to: perfect lid fit and smooth hinge operation are essential.

- Consistent print quality and surface finish: Eliminate unwanted layer lines.

- Material Certification: Ensures biocompatible plastics or food-safe coatings used for jewelry contact (if applicable).

- Transformative finishing: Post-processing improves basic printing results:

- Metal: Polish, sandblast for satin elegance, screen print or laser engraved text/graphics.

- polymer: Smoothing steam bath (SLA resin), precision support removal (SLS/SLA), expert priming and painting/coating, exquisite finishing. This differentiates arts and crafts projects from premium heirlooms.

- Grand announcement: Place your heartfelt gift in an extraordinary container. The unboxing ceremony becomes an unforgettable expression of your unique bond.

GreatLight creates the romantic edge

Creating beautiful, functional gift boxes requires more than just a printer. it requires Master precision, materials science and meticulous finishing. As a professional rapid prototyping manufacturer specializing in metal and polymer solutions, Gretel has the core capabilities necessary to create stunning Valentine’s Day gift boxes:

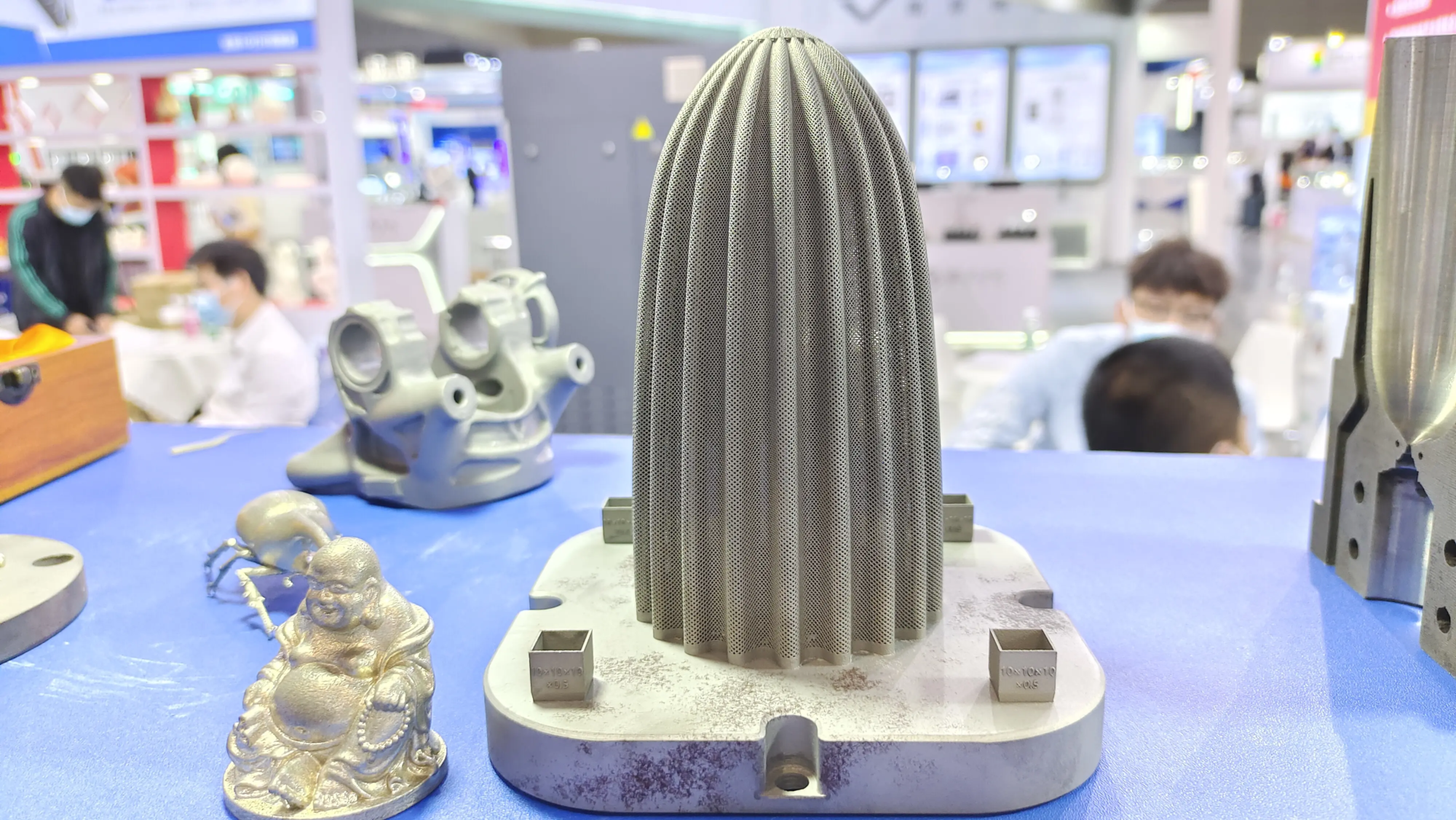

- Cutting-edge SLM expertise: Laser melting can produce complex metal boxes with complex geometries not possible through casting. Stainless steel or titanium becomes your canvas.

- Multifunctional polymer manufacturing: Utilize advanced SLS and stereolithography machines to create stunningly detailed polymer boxes in a variety of colors and finishes.

- Uncompromising precision: Strict quality control ensures that each hinge is perfectly aligned, each latch has satisfactory accuracy, and dimensions exceed standard tolerances.

- Perfect service: In addition to printing, we offer comprehensive post-processing – intricate polishing, intricate painting/coating, professional assembly – to turn your 3D print into a polished jewelry box worthy of its contents.

- Material mastery: Access to and expertise in engineering-grade materials are ideal for craft applications requiring durability and tactile aesthetics.

- Fast and refined: Leverage rapid prototyping speed to iterate and deliver faster without sacrificing quality.

Conclusion: Making memories tangible

3D printed Valentine’s Day gift boxes go beyond mere functionality. It transforms a gift into an immersive narrative—a story thoughtfully crafted, crafted, and ultimately evocative of wonder. It displays unparalleled thoughtfulness and ingenuity that amplifies the emotion of the gift it contains tenfold. Among the many predictable gifts, it speaks of originality and dedication. This Valentine’s Day, it’s not just about wrapping your love; Design its presentation. Put the effort into creating a custom container for your love – it’s a tangible testament to your unique connection that will be cherished long after the chocolate is gone.

FAQ: Answers to your 3D printed Valentine’s Day gift box questions

Q1: How soon should I start designing and ordering custom Valentine’s Day boxes?

one: Get started now! While rapid prototyping is faster than traditional manufacturing, making it perfect takes time. Consider design iterations (1-2 weeks, especially for complex concepts), printing complexity (each batch of metal can take days), and complex finishing/curing (polishing, painting, coating adds time). designed to start the process At least 4-6 weeks Before Valentine’s Day. Rush service may work for simpler designs, but compromises reduce room for improvement.

Question 2: What material is safest for storing jewelry or edible gifts?

A: Prioritize biometric materials or inert metals:

- Jewelry: Choose biocompatible resins (check specific certifications, such as USP Class VI), stainless steel 316L, uncoated titanium, or high-quality polymers such as polypropylene PP. Ensure that the applied finish/coating is also skin/food safe in the event of contact.

- Edibles (such as chocolate): use Food safety certification Sterilizable materials such as stainless steel 316L or biocompatible resins/polymers. Use certified food-safe removable inserts or liners (silicone, parchment paper) to create an extra barrier. The use of porous materials should be avoided unless properly sealed.

Q3: How detailed can the design be?

A: Highly complex designs are achievable! Among the niche markets competing with CNC machining and injection molding capabilities are the following capabilities:

- Advanced Industrial Models: Seamlessly handle extremely delicate filigree, micro-texturing, complex hollow structures and ultra-fine engravings.

- Precision Focus: Make sure your service provider specializes in sub-millimeter detail resolution and understands optimized design for the specific technology (SLM/SLA outperforms SLS in terms of fidelity, etc.).

- Detail constraints: Practical balance of design aspirations.

Q4: Can I print directly with non-ferrous metal?

A: Metal is usually printed in its original state (silver/gray stainless steel, gray titanium). However, coloring is achieved through complex techniques Post-processing:

- polishing: Create a mirrored finish.

- Sandblasting/Powder Coating: Available in unique textures and colors.

- Immersion Dye/Paint: Used for Selective Laser Sintering (SLS) printing to produce vivid tones not found in metals.

Question 5: What is the difference between professional-grade printed packaging boxes and amateur-grade printed packaging boxes?

A: The main difference is the quality of the finishing:

- Surface perfection: Layer lines are removed by careful sanding/polishing/bathing, and a smooth surface can only be achieved with significant improvement.

- Precision fit: Consistent dimensional accuracy ensures a perfect lid fit, beyond what is possible with consumer machines.

- Paint/powder coating: Achieving a pristine, durable finish requires industrial spray/curing equipment.

- Material integrity: Use advanced materials optimized for functionality.

Q6: How do I make sure the box fits my specific gift perfectly?

A: Accurate measurements are crucial:

- Measure the gift itself accurately (dimensions – length x width x height).

- Clearly communicate these dimensions and any tolerances (tight/exact/slightly over) to your designer/service provider.

- Specify whether the gift requires padding/lining and whether an insert is required.

Ready to design something unforgettable? Create a timeless symbol of your affection.