As we continue to push the boundaries of innovation and technology, the world of 3D printing opens new avenues for creative expression and functional design. One such example is the 3D printed water plant holder, which demonstrates the versatility and accuracy of 3D printing technology. In this article, we will dig into the world of 3D printed water plant holders, exploring its advantages, design possibilities, and the role of professional rapid prototyping manufacturers such as Greatlime in bringing these innovative products into reality.

The concept of 3D printing has revolutionized the way we approach design and manufacturing. By allowing the creation of complex geometric shapes with unprecedented precision and custom products, 3D printing makes it possible to produce items that were previously unfabricated using traditional methods. 3D printed water plant holders are a great example of such a combination of aesthetic appeal with simplicity of functionality.

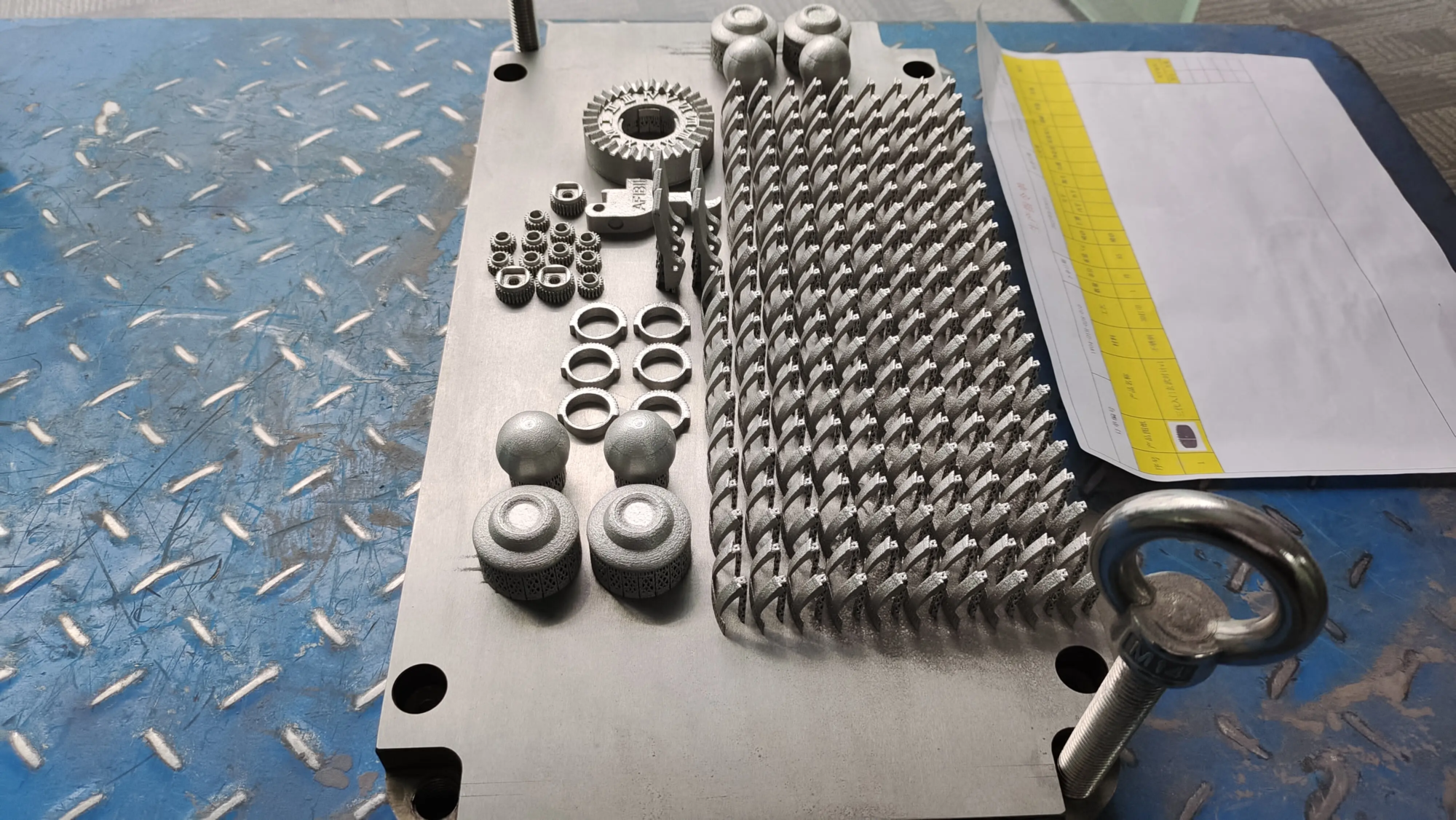

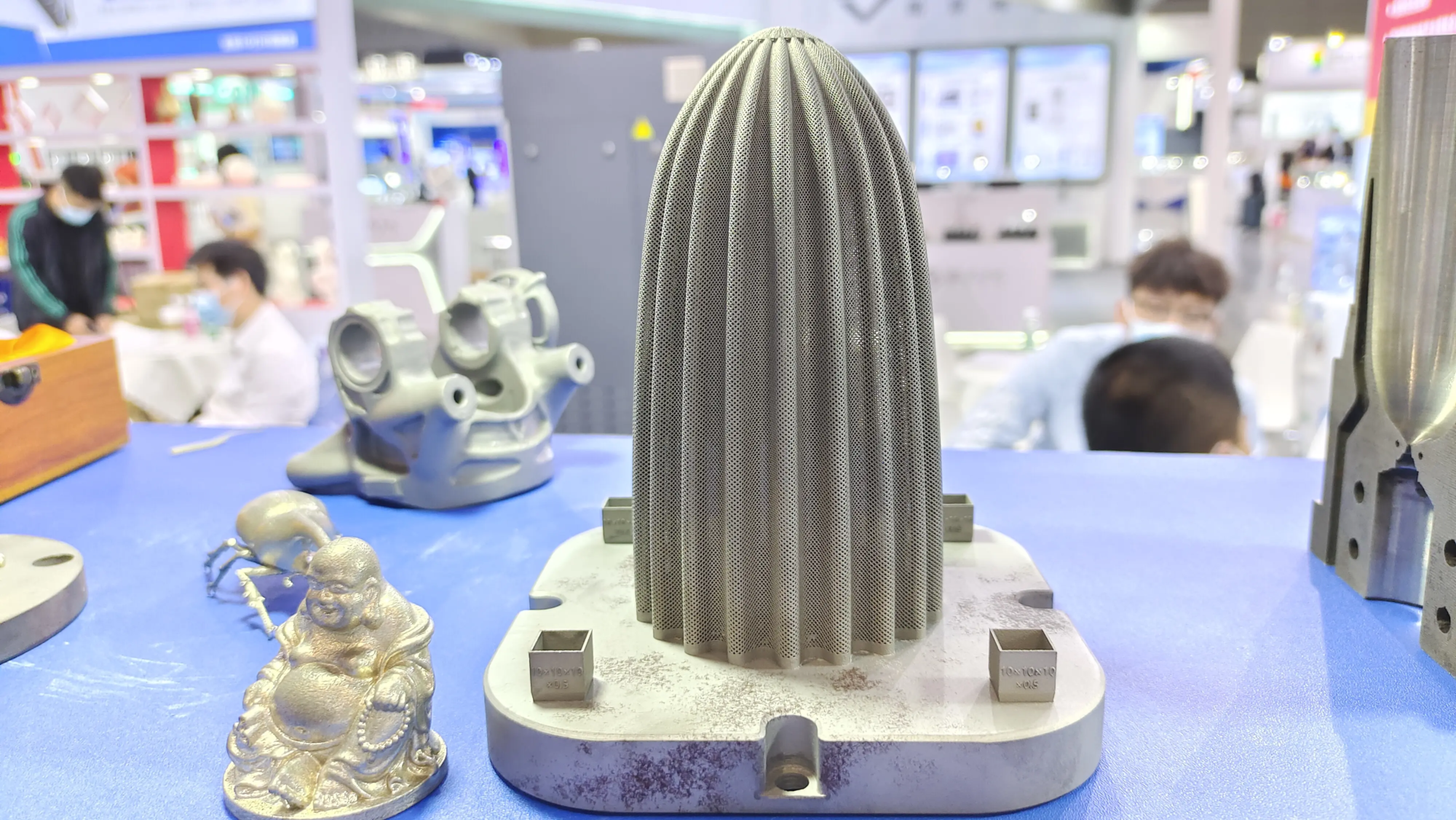

Designers and engineers can now create complex and beautiful designs for water plant holders, taking into account the specific needs of the plants and the aesthetic preferences of the customers. Using advanced SLM (selective laser melting) 3D printers such as Greatlime, high-quality metal parts with complex geometries can be produced, allowing for the creation of plant scaffolds that are not only visually stunning, but also long-lasting.

One of the important advantages of 3D printed water plant holders is their customization potential. Using 3D printing, designers can take into account factors such as root depth, water circulation, and light exposure, creating holders tailored to specific plant species. This level of customization can lead to healthier, more prosperous plants, and a unique and personalized aesthetic that reflects the owner’s style and preferences.

In addition, using 3D printing technology can create complex internal structures and geometric shapes, which can enhance the growth and well-being of plants. For example, designers can build complex networks of water access and aeration systems to ensure the factory gets the best water and oxygen. This level of precision and control can improve plant health, reduce maintenance, and a more sustainable and environmentally friendly plant care approach.

Professional rapid prototyping manufacturers, such as Greatlight, play a crucial role in bringing these innovative products to life. With their expertise in rapid prototyping of SLM 3D printers and metal parts, they can produce high-quality water plant holders with complex geometric shapes and custom designs. Greatlight is committed to providing one-stop post-processing and completion services, ensuring that the final product meets the highest standards of quality and accuracy, making it an ideal partner for designers and entrepreneurs to bring their innovative ideas to the market.

In short, 3D printed water plant holders represent a cutting-edge fusion of technology, design and sustainability. This innovative product has the potential to customize, sophisticated designs and improve plant health and will revolutionize the way we approach plant care and home decor. As technology continues to evolve and improve, we can expect to see more exciting and innovative applications of 3D printing in water plant holders and beyond.

FAQ:

Q: What is 3D printing and how does it work?

A: 3D printing is a manufacturing process that creates digitally designed physical objects by layering materials such as metal, plastic and ceramics. The process involves the use of a 3D printer that reads design files and lays out material layer by layer according to design specifications.

Q: What are the benefits of 3D printing of water plant holders?

A: The benefits of 3D printing of water plant holders include customization potential, complex design possibilities, improved plant health and durability. They can also be designed to be sustainable and environmentally friendly, making them an attractive choice for environmentally friendly consumers.

Q: How to customize my 3D printed water plant holder?

A: You can customize 3D printing of aquaplant holders by working with designers or engineers to create unique designs that meet your specific needs and preferences. This can include factors such as plant species, deep roots, water circulation and light exposure, as well as aesthetic considerations such as color, texture and shape.

Q: What materials can 3D printed water plant holders use?

A: Various materials can be used in 3D printing water plant holders, including metals, plastics and ceramics. The choice of materials will depend on durability, sustainability and aesthetic appeal, as well as specific requirements of the plant and the environment in which it is placed.

Q: How do I take care of my 3D printed water plant holder?

A: To take care of your 3D printed water plant holder, follow the manufacturer’s instructions for maintenance and maintenance. This may include regular cleaning of the holder, monitoring water levels and circulation, and ensuring that the plants get the best light and nutrients. Regular maintenance will help extend the lifespan of the holder and ensure the health and well-being of the plants.

ISO 9001 Factory