Utilizing innovation: The rise of 3D printed hydroelectric towers with excellent performance

The pursuit of efficient, sustainable and high-performance water management infrastructure has found a strong ally: Metal 3D printing. Hydroelectric towers are key components from hydroelectric power and large-scale cooling towers to advanced hydroponic installations and industrial reservoirs, and have gained enormous benefits from this cutting-edge technology. These structures are traditionally manufactured using casting, forging or processing, and often face limitations of design complexity, lead time and cost, especially for custom applications. Input Selective Laser Melting (SLM) 3D Printing – A game-changer that enables the production of hydraulic towers with unprecedented precision, functionality and speed.

Breaking the Mold: The Limitations of Traditional Manufacturing

Conventional methods for manufacturing complex metal hydroelectric tower assemblies involve multi-step processes. Complex internal cooling channels, optimized aerodynamic profiles or lightweight lattice structures are very difficult, if not impossible, to achieve cost-effectiveness. Customization means expensive tools, longer waiting time and a lot of waste of materials. These limitations often lead to compromises in the hydraulic efficiency, thermal performance, structural integrity or lifetime of the tower.

SLM 3D Printing: Revolutionary Water Tower Manufacturing

Leading metal additive manufacturing (AM) technology, selective laser melting (SLM), solves these challenges directly. The following are:

-

Free design freedom: SLM uses high-power lasers to melt metal powder to build parts layer by layer. This allows creating previously impossible geometric shapes:

- Complex internal channels: Optimized, bionic-like cooling or water flow channels can be printed directly Within The tower structure itself, maximizing heat dissipation or fluid dynamic efficiency.

- Lightweight topology optimization: AI-driven design software combined with SLM can create strong, rigid structures with minimal material that focus on strength only when needed. This reduces weight (critical for rotating components or large structures) and material costs.

- Integrated features: The fins, mounting points, nozzles and sensor housing can be combined into a single printed part, eliminating assembly steps and potential leak points.

-

Outstanding speed in prototyping and production: SLM significantly reduces lead times, especially for complex or custom components. Digital design translates directly into physical components, eliminating the need for expensive and time-consuming tools. Functional prototypes can be tested quickly and accelerated the development cycle. For end-use parts, small batch production (SBP) becomes very economical.

-

Excellent material properties: SLM utilizes high purity metal powders. For hydropower towers, industry-related materials include:

- Stainless steel (316L, 17-4 pH): Excellent corrosion resistance to water environment.

- Lightweight alloy (titanium Ti6al4v, aluminum ALSI10MG): Ideal for structures that require strength to weight ratio.

- Tool Steel (H13, Maraging Steel): High hardness and wear resistance for harsh tribological applications.

- Exotic Alloy (Inconel 625/718): For extremely high heat and corrosion resistance.

Compared with traditional methods, high energy density and rapid cooling in SLM can even lead to finer microstructures, potentially enhancing mechanical properties.

- Reduce waste and cost efficiency: Additive manufacturing is inherently wasteful. Adding the material exactly where it is needed is in sharp contrast to the subtraction method of subtracting up to 80-90% of the material. For high-value metals or complex parts, this means a significant cost savings over the part life cycle.

GRESTLIGHT: Your pioneer in accurate SLM printing hydropower components

At Greatlight, we are at the forefront of leveraging SLM technology to solve complex rapid prototyping and production challenges, including those of hydropower towers. Our commitment is unwavering:

- Advanced SLM Fleet: We operate the most advanced SLM 3D printers with large build volumes and meticulous process controls to handle demanding water tower geometry.

- Material mastery: We offer a wide range of specialized metal powders and have expertise in the best materials for specific tower applications such as corrosion resistance, strength, thermal conductivity.

- Full Spectrum Service: Gremply offers a true one-stop solution:

- Design of Additive Manufacturing (DFAM) Support: Our engineering team works with you to optimize your water tower design for printability, performance and cost.

- Precision printing: A strict quality process ensures dimensional accuracy and consistent mechanical properties.

- Comprehensive post-processing: We handle all necessary completions: pressure relief, heat treatment (HTA), accurate CNC machining of critical interfaces, surface finishes (polishing, bead blasting) and quality inspection (CMM, CT scan, etc.) to meet the exact specifications.

- Quick customization: Whether it is a rapid iteration during R&D or a final use deployment, we can quickly produce custom water tower components. Traditional manufacturing cannot achieve this agility.

Transformative Applications

The impact of 3D printing water towers spans across sectors:

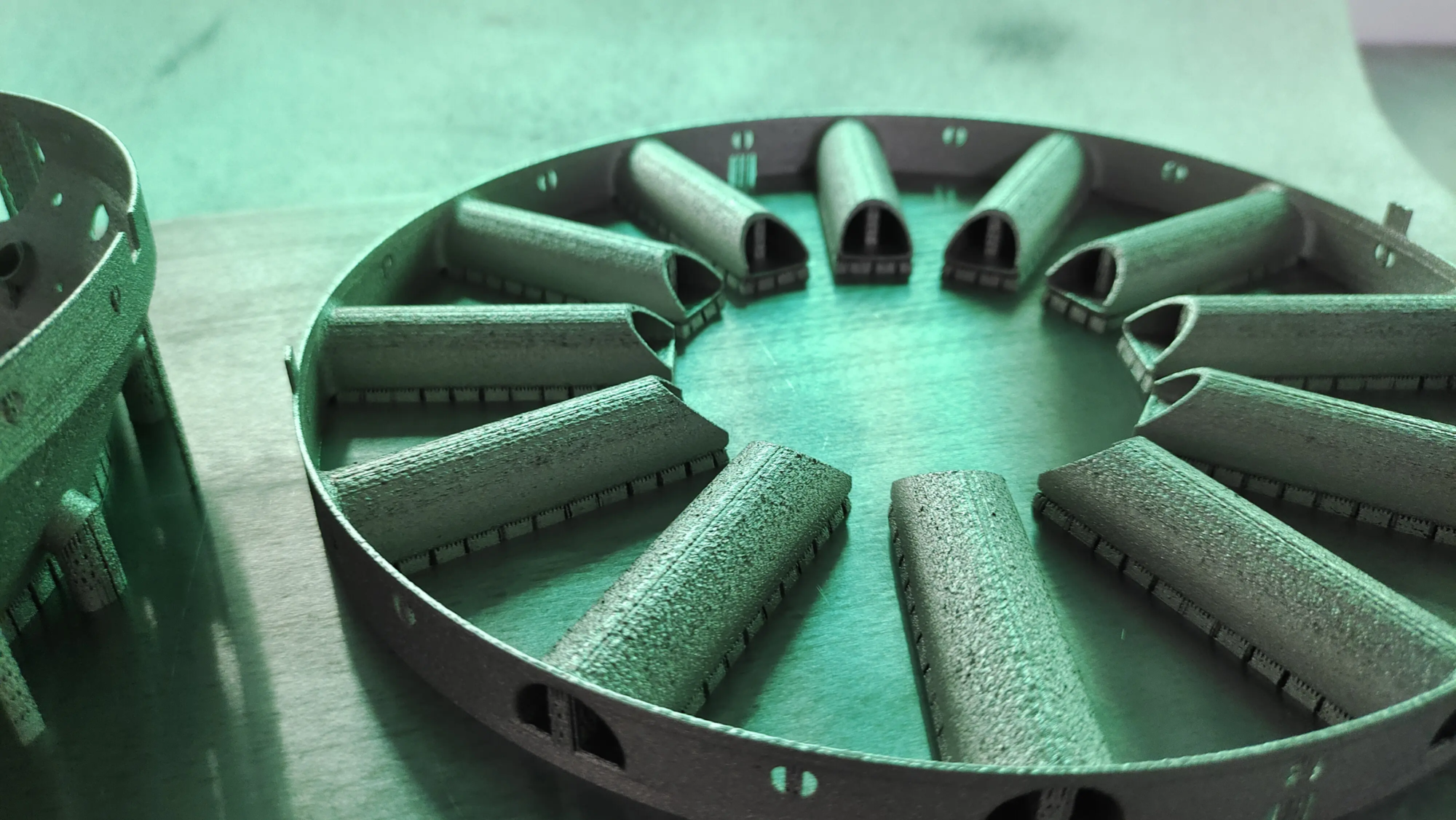

- Hydropower: Lightweight aerodynamic-optimized turbine assembly with integrated cooling nozzle assembly and complex air intake structure.

- Industrial Cooling: Towers with complex internal lattice structures maximize surface area and heat exchange efficiency, potentially reducing water consumption.

- Water treatment and reservoirs: Customizable accessories, filter housing and flow control elements with integrated channels for reagent mixing or sampling.

- Advanced hydroponics method: Efficient nutrient delivery systems, nozzles and structural components that require specific corrosion characteristics.

- R&D: Test rig components and scale models are quickly created for experimentation and optimization.

in conclusion

3D printing, especially SLM metal printing, is driving Hydro Tower design and manufacturing into a new era. It removes the limitations of the legacy process, allowing lighter, stronger, more efficient, more precise custom components to change the performance and sustainability of water-related systems. Greglight is ready as your expert partner on this journey. With our advanced SLM capabilities, deep material knowledge and comprehensive finishing services, we provide high-precision, fast-producing hydraulic tower solutions to meet your most challenging requirements. Embrace the Future of Innovation – Let’s design peak performance together.

FAQ: 3D printing hydropower tower

Q1: What type of water tower can be printed in 3D?

A1: Metal 3D printing stands out on complex components Within Water tower system. This includes impeller, manifold, nozzle assembly, specialized accessories, heat exchanger core with complex internal channels, lightweight structural elements, and custom couplers/covers. The entire large overall tower structure is usually not 3D printed, but is used to optimize subcomponents.

Q2: Why is SLM the preferred 3D printing method for water towers?

A2: Selective laser melting (SLM) can be used with a variety of high-performance metal powders (stainless steel, titanium, aluminum, nickel, nickel alloys) for harsh hydraulic environments (pressure, corrosion, wear). SLM produces fully dense parts with excellent mechanical properties, suitable for critical components for functional prototypes and end-use applications.

Q3: How does 3D printing improve the performance of water towers?

A3: Key benefits include:

- Enhanced hydraulic efficiency: Optimized internal channels minimize friction and pressure drop.

- Excellent cooling/thermal management: Complex conformal cooling channels maximize heat transfer.

- lose weight: Topologically optimized structure reduces quality without sacrificing strength.

- Reduce leak points: Component merger minimizes joints and seals.

- Faster iteration: Rapid prototyping accelerates design optimization.

Question 4: Is 3D printing of metal hydroelectric towers cost-effective?

A4: It can be cost-effective, especially for complex designs or low to medium production. Savings come from:

- Eliminate expensive tools (molds, molds).

- Significantly reduce material waste.

- Reduce assembly costs through part consolidation.

- Shorten the lead time for development and production.

Compared with traditional methods, cost-effectiveness increases significantly with increasing complexity.

Q5: Which materials are suitable for 3D printing hydroelectric towers?

A5: Material selection depends on the application:

- Corrosion resistance (water environment): Stainless steel 316L, duplex steel, titanium Ti6al4v, Inconel 625/718.

- High strength to weight ratio: Titanium Ti6al4v, Aluminum ALSI10MG, ScalMalloy®.

- Wear resistance: Tool steel (H13, Maraging Steel), star alloy.

- High temperature performance: inconel grade, specific tool steel. Greglight provides guidance on material selection.

Q6: What post-processing steps are required to 3D printing water tower parts?

A6: Post-processing is critical to function and durability:

- Support removal: The support structure used during the printing process must be carefully removed.

- Stress relief/heat treatment (HTA): Reduce residual stress and optimize mechanical properties/microstructure.

- Processing: CNC machining critical sealing surfaces, threaded or high resistance interfaces.

- Surface finish: Polish, bead blast or coating to improve corrosion resistance, reduce friction or for aesthetic reasons.

- Quality Control: Non-destructive testing (such as CT scans) and metrology inspection (CMM).

Greglight provides comprehensive internal post-processing.

Question 7: How quickly can Greatlight deliver customized 3D printed water tower components?

A7: The delivery time is much shorter than that of traditional manufacturing. For R&D and rapid prototyping, functional prototypes can often be delivered within days to weeks, speeding up design verification. For end-use serial batch production (SBP), the advance time depends on the complexity and volume of the part, but is usually much faster than casting or complex machining. Direct digital Fabriqués eliminates tool delays.

Customize next-generation hydro tower components with Greatlime. Leverage our expertise in SLM 3D printing and precise completion to achieve excellent performance and efficiency. Contact us now to discuss your project!